Sucker for pipettor

A pipette and suction port technology, applied in the field of pipettes, can solve problems such as operation influence and suction port blockage, and achieve the effect of improving efficiency and saving experimental time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

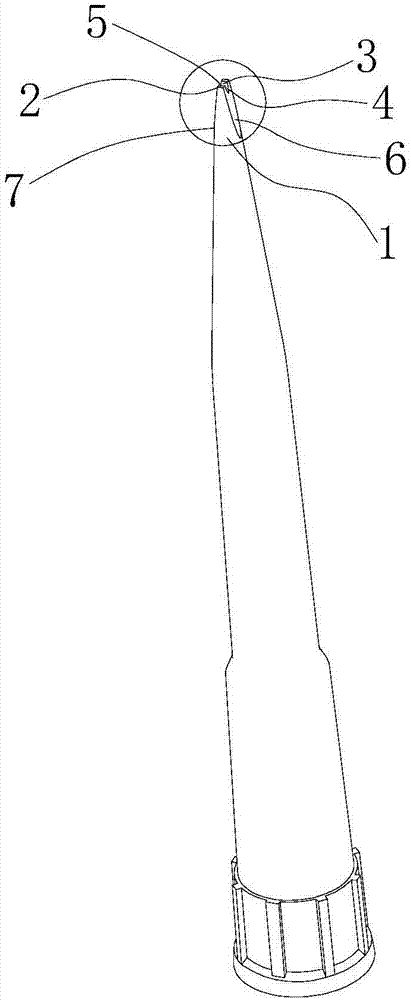

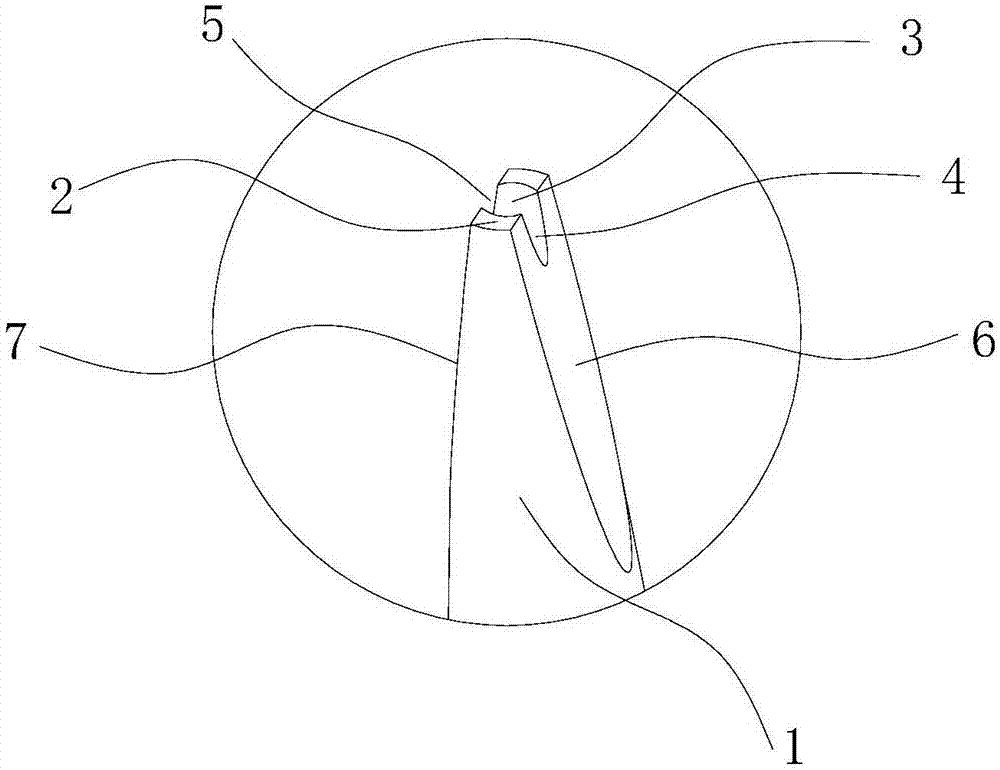

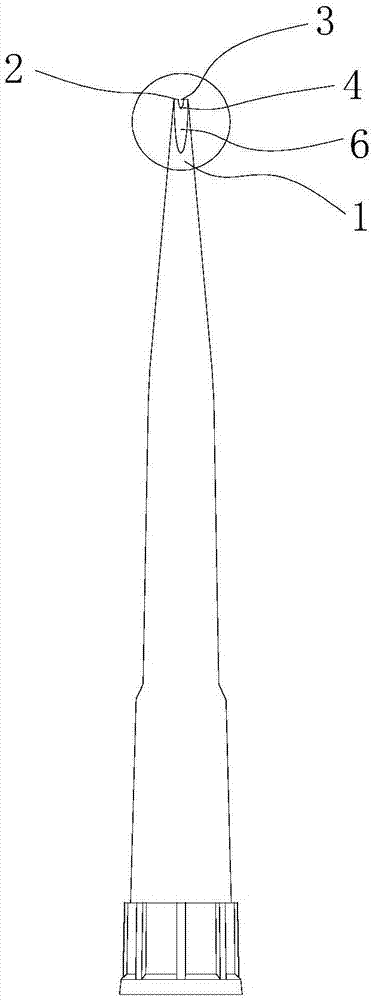

[0024] combine Figure 1 to Figure 5 , to describe this embodiment in detail. In this embodiment, the diameter of the liquid suction port is 0.5 mm, and the distance between the two intersection lines is 0.2-0.4 mm, which is 0.35 mm in this embodiment. The range of the included angle between the first cut plane and the second cut plane is 18-20°, and 19° is selected in this embodiment. The distance between the apex of the opening and the liquid-absorbing end surface is 0.4-1.0 mm, and in this embodiment, it is 0.6 mm. The distance between the vertices of the first cut plane and the second cut plane and the liquid-absorbing end face is 3-6 mm, which is 3.5 mm in this embodiment.

Embodiment 2

[0026] In this embodiment, the diameter of the liquid suction port is 0.5 mm, and the distance between the two intersection lines is 0.2-0.4 mm, which is 0.2 mm in this embodiment. The range of the included angle between the first cut plane and the second cut plane is 18-20°, and 18° is selected in this embodiment. The distance between the apex of the opening and the liquid-absorbing end surface is 0.4 mm, and in this embodiment, it is 0.6 mm. The distance between the vertices of the first cut plane and the second cut plane and the liquid-absorbing end face is 3-6 mm, which is 3 mm in this embodiment.

Embodiment 3

[0028] In this embodiment, the diameter of the liquid suction port is 0.5 mm, and the distance between the two intersection lines is 0.2-0.4 mm, which is 0.4 mm in this embodiment. The range of the included angle between the first cut plane and the second cut plane is 18-20°, and 20° is selected in this embodiment. The distance between the apex of the opening and the liquid-absorbing end surface is 1.0 mm, which is 0.6 mm in this embodiment. The distance between the vertices of the first cut plane and the second cut plane and the liquid-absorbing end face is 3-6 mm, which is 6 mm in this embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com