Preparation method and preparation system of enhanced hollow fiber micro-filtration membrane

A preparation system and enhanced technology are applied in the field of preparation of polymer hollow fiber membranes, which can solve the problems of high production cost, unsatisfactory processing effect, complicated processing, etc., achieve less labor input, save adjustment and cleaning work, Guaranteed uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

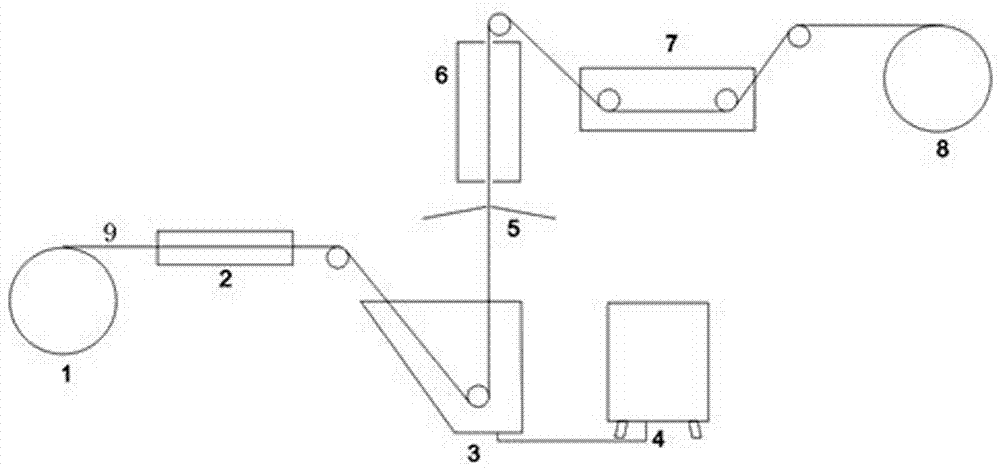

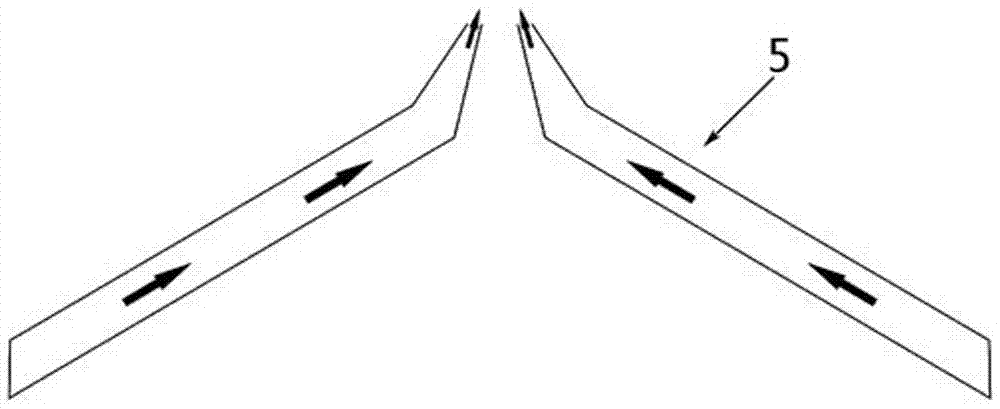

[0025] A simple and stable method for preparing a reinforced hollow fiber composite microfiltration membrane provided by the present invention, the steps are as follows (please combine figure 1 , 2 ):

[0026] Step 1: Pre-processing

[0027] Contaminants and moisture on the surface of the braided tubing are removed first. The specific treatment method can be selected according to the situation, such as pulling the braided pipe to the pre-treatment facility 2, cleaning the rinsing tank, and then drying with hot air. It is also possible to modify the surface properties of the braided tube first, such as plasma treatment, so that the surface has new functional groups to obtain special properties.

[0028] Step 2: Dip Coating

[0029] Pull the braided tube that removes pollutants and moisture into the casting solution tank of the coating device 3 filled with protective gas, dip it in the casting solution, and then pull the braided tube impregnated with the casting solution ver...

Embodiment 1

[0036] Embodiment 1: Preparation of polyvinylidene fluoride (PVDF) film

[0037] The ratio of casting liquid is PVDF 16wt%, PEG400 5wt%, PVP30K 4wt%, Tween 2wt%, pure water 0.5wt%, DMAc72.5wt%. Pour the above-mentioned materials into the casting solution tank 4, at 70°C, stir evenly for defoaming, then inject nitrogen gas to pressurize to 2 atm, and send the casting solution into the casting solution tank 3 for use.

[0038] Select a polyester low-elastic yarn braided tube 9 with an outer diameter of 2.0 mm, and send it to the pre-treatment device 2 after being pulled by the unwinding device 1, and dried at 60°C for 0.5 minutes, and then pulled and sent to the casting solution tank 3 for casting. The temperature in the membrane liquid tank 3 is 70° C., so that the braided pipe 9 passes through the conduction wheel immersed in the casting liquid 12 cm below the liquid surface. The braided pipe 9 coated with the casting solution enters the steam bath 7 after passing through the...

Embodiment 2

[0040] Embodiment 2: Preparation of polysulfone PS membrane

[0041] The ratio of casting solution is: PS 18wt%, PEG400 4wt%, PVP30K 6wt%, pure water 1.5wt%, DMAc 70.5wt%. The temperature of the casting bath was set at 60°C. Other processing parameters are identical with embodiment 1.

[0042] Performance test: After testing, the pure water flux of the obtained enhanced hollow fiber microfiltration membrane is 1158L / m2h (0.1MPa, 25°C), the bubble point of the membrane filament is greater than 0.25MPa, and the burst strength is greater than 0.60MPa. The enhanced PS obtained in the present invention The combination strength of microfiltration membrane and braided tube is high.

PUM

| Property | Measurement | Unit |

|---|---|---|

| bursting strength | aaaaa | aaaaa |

| bursting strength | aaaaa | aaaaa |

| bursting strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com