Fireproof type bus duct with heat dissipation rings

A technology of bus duct and heat dissipation ring, which is applied in cooling bus device, fully enclosed bus device, etc., can solve the problems of weak overload capacity of bus duct, rarely using fireproof material for bus duct shell, and poor fire resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

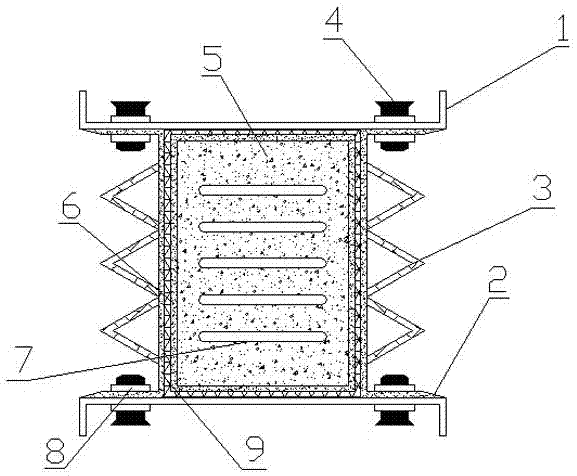

[0024] Such as figure 1 As shown, a fire-resistant bus duct with a heat dissipation ring has the following structure: the upper and lower ends of the bus duct are fixedly provided with a cover plate 1, the two sides of the bus duct are fixedly provided with side plates 2, and the side plates 2 are fixedly provided with heat dissipation rings 3. Fixing screws 4 are fixed on the cover plate 1, fixing washers 8 are fixed on the fixing screws 4, a number of conductive plates 7 are evenly arranged inside the bus duct, and a refractory filling layer with a rectangular cross section is fixed outside the conductive plates 7 5. An insulating layer 6 is fixedly arranged on the outer side of the refractory filling layer 5 , and an electromagnetic shielding layer 9 with a rectangular cross section is fixedly arranged on the outer layer of the insulating layer 6 .

[0025] The above-mentioned cover plate 1 and side plate 2 are both made of a magnesium-aluminum alloy material, wherein: the ...

Embodiment 2

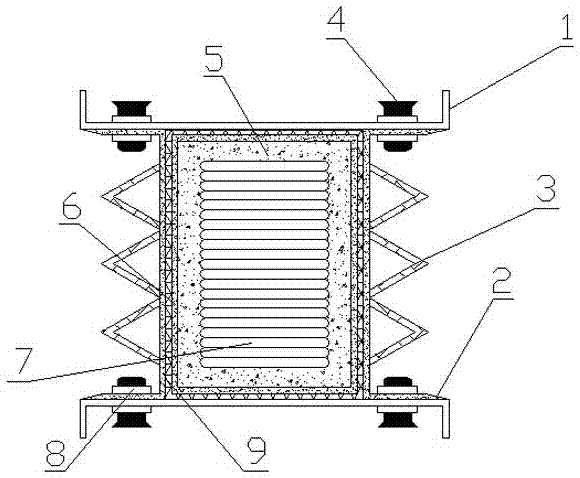

[0035] Such as figure 2 As shown, a fire-resistant bus duct with a heat dissipation ring has the following structure: the upper and lower ends of the bus duct are fixedly provided with a cover plate 1, the two sides of the bus duct are fixedly provided with side plates 2, and the side plates 2 are fixedly provided with heat dissipation rings 3. Fixing screws 4 are fixed on the cover plate 1, fixing washers 8 are fixed on the fixing screws 4, a number of conductive plates 7 are evenly arranged inside the bus duct, and a refractory filling layer with a rectangular cross section is fixed outside the conductive plates 7 5. An insulating layer 6 is fixedly arranged on the outer side of the refractory filling layer 5 , and an electromagnetic shielding layer 9 with a rectangular cross section is fixedly arranged on the outer layer of the insulating layer 6 .

[0036] The above-mentioned cover plate 1 is designed as a groove-shaped structure with a groove depth of 2 cm. There are at ...

Embodiment 3

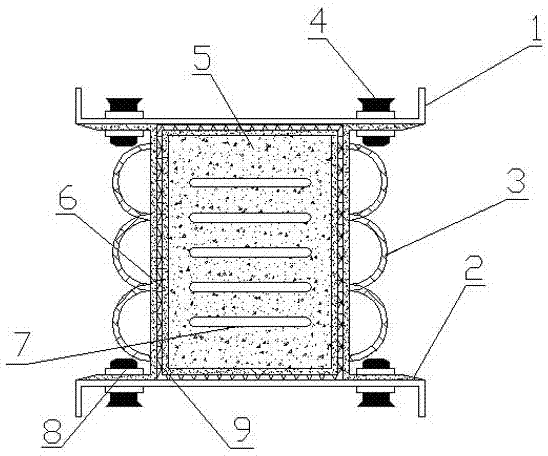

[0043] Such as image 3 As shown, a fire-resistant bus duct with heat dissipation ring has the following structure: the upper and lower ends of the bus duct are fixedly provided with cover plates 1, the two sides of the bus duct are fixedly provided with side plates 2, and the side plates 2 are fixedly provided with heat dissipation The ring 3, the cover plate 1 is fixed with a fixing screw 4, the fixing screw 4 is fixed with a fixing gasket 8, a number of conductive plates 7 are uniformly arranged inside the bus duct, and a refractory filling with a rectangular cross section is fixed outside the conductive plate 7 layer 5, an insulating layer 6 is fixedly arranged on the outside of the refractory filling layer 5, and an electromagnetic shielding layer 9 with a rectangular cross section is fixedly arranged on the outer layer of the insulating layer 6.

[0044] The above-mentioned cover plate 1 is designed as a groove structure with a groove depth of 3 cm, at least two fixing s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com