Hydraulic fixing type sampler and sampling method thereof

A sampler and fixed technology, applied in the field of hydraulic fixed samplers, can solve the problems of single sampling tube, high sampling cost, inability to adapt to sampling tube, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

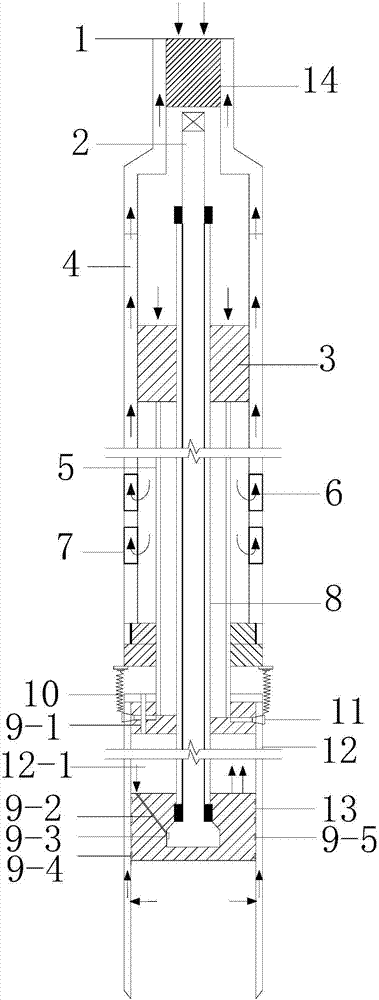

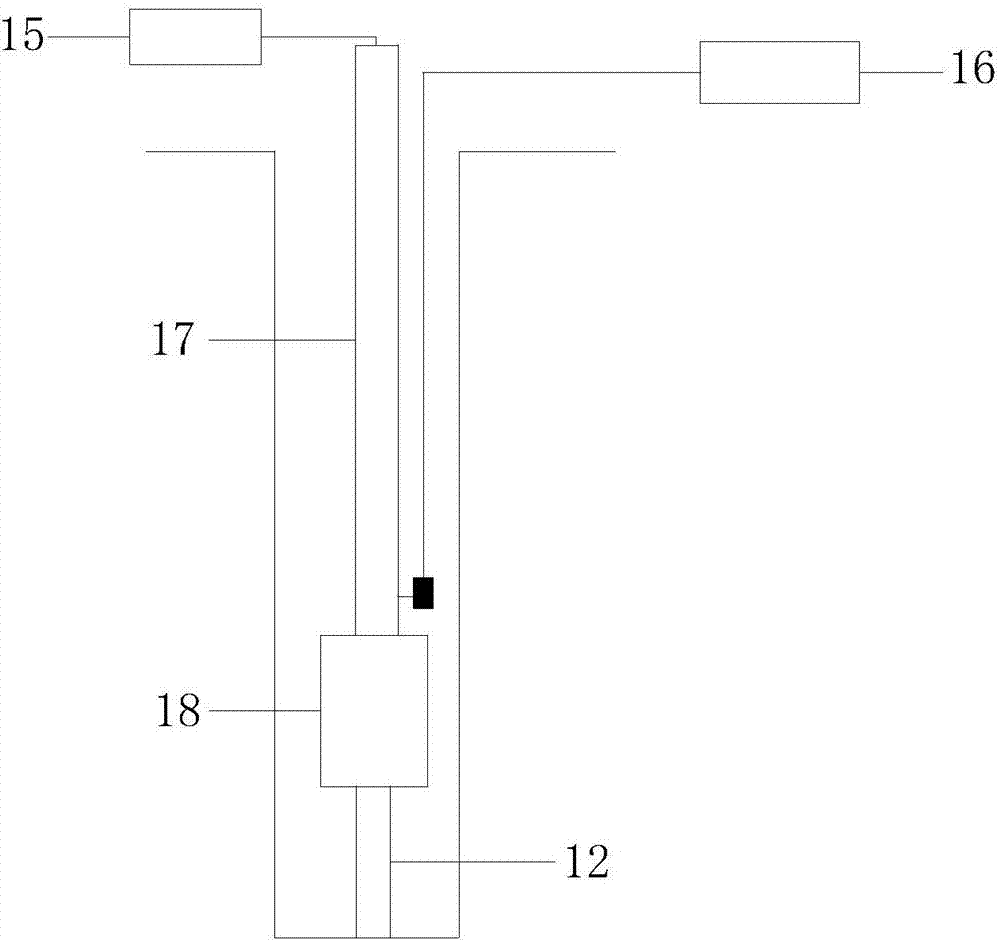

[0028] The working principle of a novel hydraulic fixed sampler of the present invention will be further described below in conjunction with the accompanying drawings.

[0029] An improved hydraulic sampler, see figure 1 , including: vacuum inner tube 2, annular piston 3, cylinder barrel 4, piston rod 5, pressure release hole 6, drain hole 7, fixed tube 8, exhaust hole 9-1, fixed ring 11, sampling tube 12, fixed piston 13. Drill pipe joint 14.

[0030] In the present invention, the vacuum inner tube 2 is the vacuum breaker added thereto, and its length spans the entire hydraulic sampler to provide a sufficient vacuum environment. The air in the sampling tube is sucked away to ensure the quality of the sample, and the upper and lower parts of the sampler are connected together with the fixed tube 8, so that the sampling tube can be continuously, stably and repeatedly sampled under the action of hydraulic pressure.

[0031] In the present invention, the fixed tube 8 is positio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com