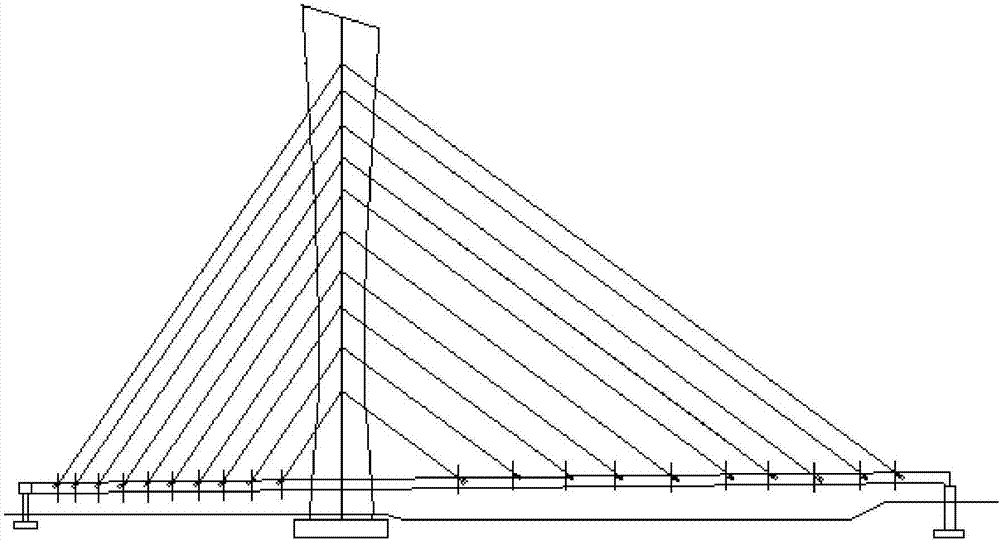

Horizontal rotation structure of ultra-large-tonnage asymmetric hybrid girder cable-stayed bridge and construction method thereof

A technology with super large tonnage and construction method, which is applied in the direction of bridges, bridge construction, erection/assembly of bridges, etc., can solve the problems of complex construction process and high construction cost, and achieve the effects of clear force, short construction period and safe construction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

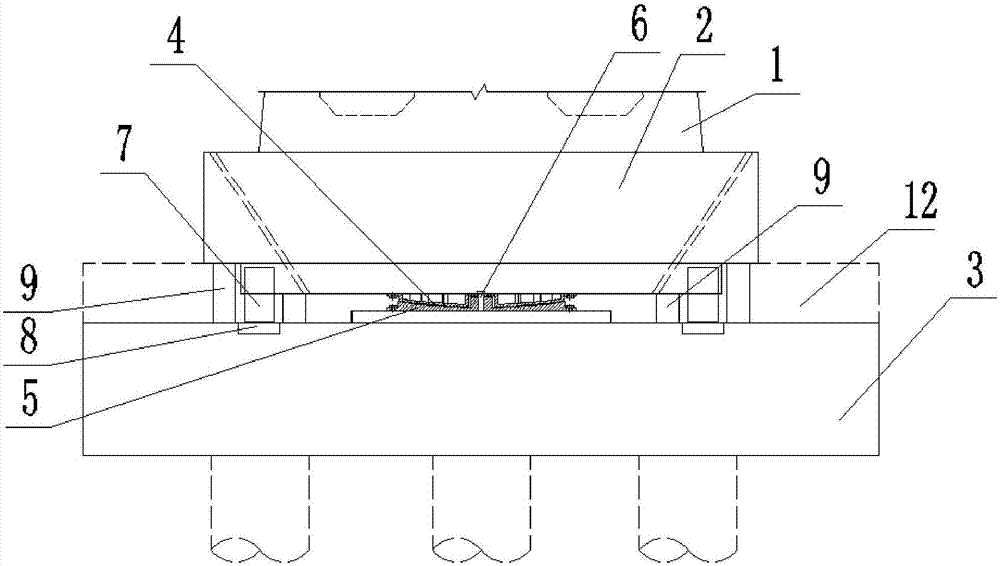

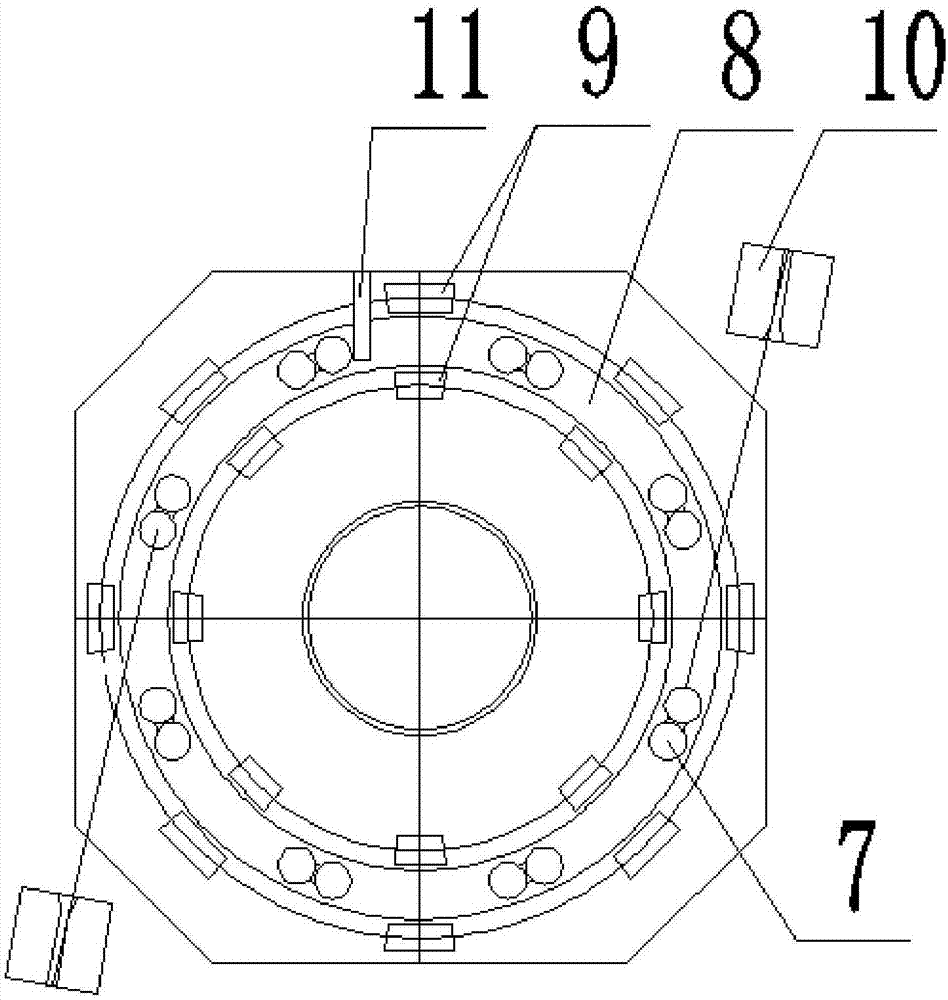

[0063] The horizontal swivel structure of a super-large tonnage asymmetric mixed girder cable-stayed bridge includes concrete foundation piles 1, caps, turntables, and swivel slide rails. The caps are divided into upper caps 2 and lower caps 3, and swivel slide rails Divided into support feet 7 and slideways 8, the upper platform 2 is provided with an upper turntable 4 and support feet 7, the lower platform 3 is provided with a lower turntable 5, positioning pins 6 and slideways 8, the upper turntable 4 and the lower The turntable 5 is connected by a positioning pin shaft 6, the upper turntable 4 is bonded to the lower turntable 5, and the support foot 7 is bonded to the slideway 8.

[0064]It also includes a support sand box 9, which is arranged on both sides of the support foot 7, and the support sand box 9 is supported between the upper bearing platform 2 and the lower bearing platform 3. The upper turntable 4 and the lower turntable 5 are bonded in spherical contact. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com