Preparation method and application of ternary nano composite of reduced graphene oxide, iron(II,III) oxide and polyaniline

A nano-composite material, ferric oxide technology, applied in anti-corrosion coatings, coatings, etc., can solve the problems of limiting the popularization and application of graphene anti-corrosion coatings, and graphene is difficult to disperse, and achieve excellent chemical resistance and salt spray resistance. , the effect of excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

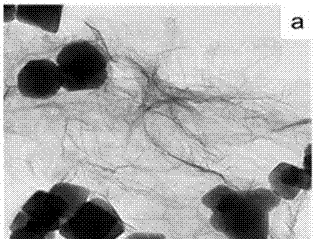

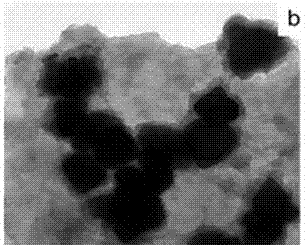

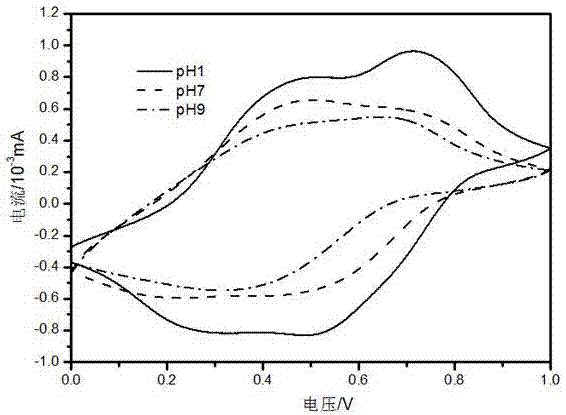

[0022] 1. Preparation of rGO / Fe 3 o 4 / PANI ternary nanocomposite material:

[0023] Weigh 0.279g of graphite oxide (rGO), 0.372g of ferric oxide (Fe 3 o 4 ) was dispersed in 150ml distilled water, transferred to a 250ml three-neck flask, and stirred ultrasonically for 30min. Then add 0.558g of aniline, and heat in a water bath at 95°C for 4 hours at a constant temperature; then cool the water bath to 0-5°C, add acetic acid, and adjust the pH of the mixed system to 1.

[0024] Weigh 1.824g of the initiator ammonium persulfate (APS) and dissolve it in 50ml of aqueous solution, transfer it to a constant pressure dropping funnel, and slowly add it dropwise to the system for 60 minutes. Reacted for 24h under ice bath conditions.

[0025] After the reaction, the product was washed with ethanol and water, and finally vacuum-dried and ground at 80°C to obtain rGO / Fe 3 o 4 / PANI (3:4:6) ternary nanocomposite material, in which the mass ratio of graphene oxide, ferric oxide and ...

Embodiment 2

[0030] 1. Preparation of rGO / Fe 3 o 4 / PANI ternary nanocomposite material:

[0031] Weigh 0.279g of graphite oxide and 0.651g of ferric oxide and disperse them in 150ml of distilled water, transfer them to a 250ml three-necked flask, and stir ultrasonically for 30min. Then add 0.558g of aniline, and heat in a water bath at 95°C for 4 hours at a constant temperature; then cool the water bath to 0-5°C, add acetic acid, and adjust the pH of the mixed system to 1.

[0032] Weigh 1.824g of initiator APS and dissolve it in 50ml of aqueous solution, transfer it to a constant pressure dropping funnel, and slowly add it dropwise to the system for 60 minutes. Reacted for 24h under ice bath conditions.

[0033] After the reaction, the product was washed with ethanol and water, and finally vacuum-dried and ground at 80°C to obtain rGO / Fe 3 o 4 / PANI ternary nanocomposite material, wherein the mass ratio of graphene oxide, ferric oxide and aniline is 3:7:6.

[0034] 2. Preparation o...

Embodiment 3

[0037] 1. Preparation of rGO / Fe 3 o 4 / PANI ternary nanocomposite material:

[0038] Weigh 0.279g of graphite oxide and 0.651g of ferric oxide and disperse them in 150ml of distilled water, transfer them to a 250ml three-necked flask, and stir ultrasonically for 30min. Then add 3.348g of aniline, and heat in a water bath at 95°C for 4 hours at a constant temperature; then cool the water bath to 0-5°C, add acetic acid, and adjust the pH value of the mixed system to 1.

[0039] Weigh 4.5g of the initiator APS and dissolve it in 50ml of aqueous solution, transfer it to a constant pressure dropping funnel, and slowly add it dropwise to the system for 60 minutes. Reacted for 24h under ice bath conditions.

[0040] After the reaction, the product was washed with ethanol and water, and finally vacuum-dried and ground at 80°C to obtain rGO / Fe 3 o 4 / PANI ternary nanocomposite material, wherein the mass ratio of graphene oxide, ferric oxide and aniline is 3:7:12.

[0041] 2. Prep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com