Non-contact type electromagnetic brake

An electromagnetic brake, non-contact technology, applied in the direction of electric brake/clutch, permanent magnet clutch/brake, electric components, etc., can solve the problems of high noise, high brake friction and dust pollution, large device loss, etc. Noise, the effect of solving the poor braking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention is further described below in conjunction with accompanying drawing:

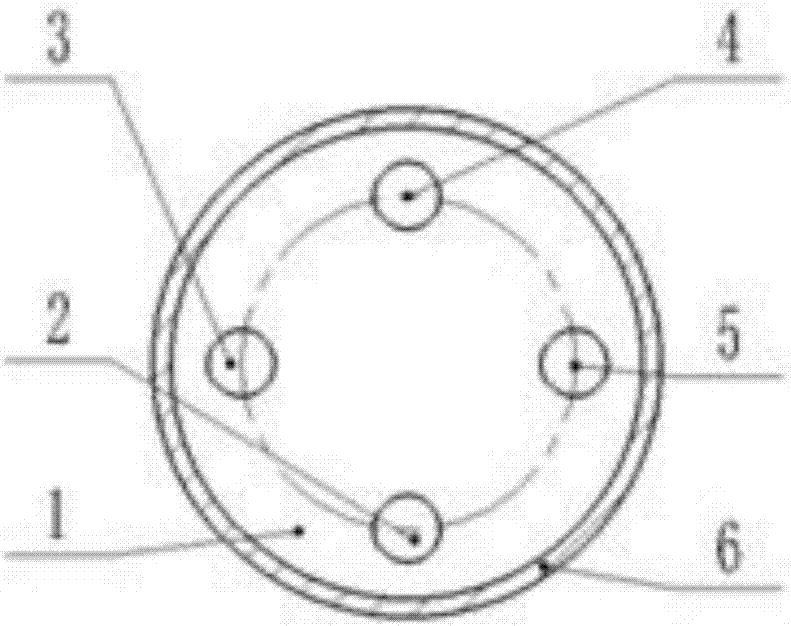

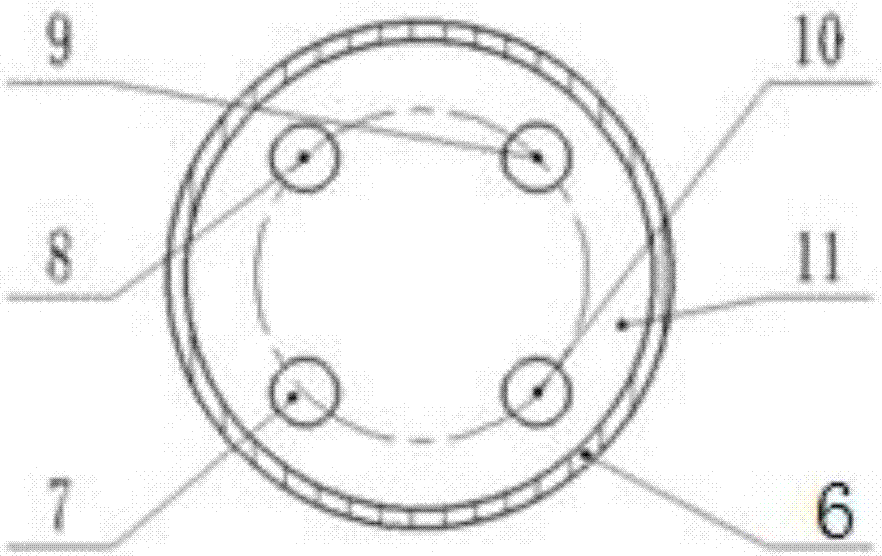

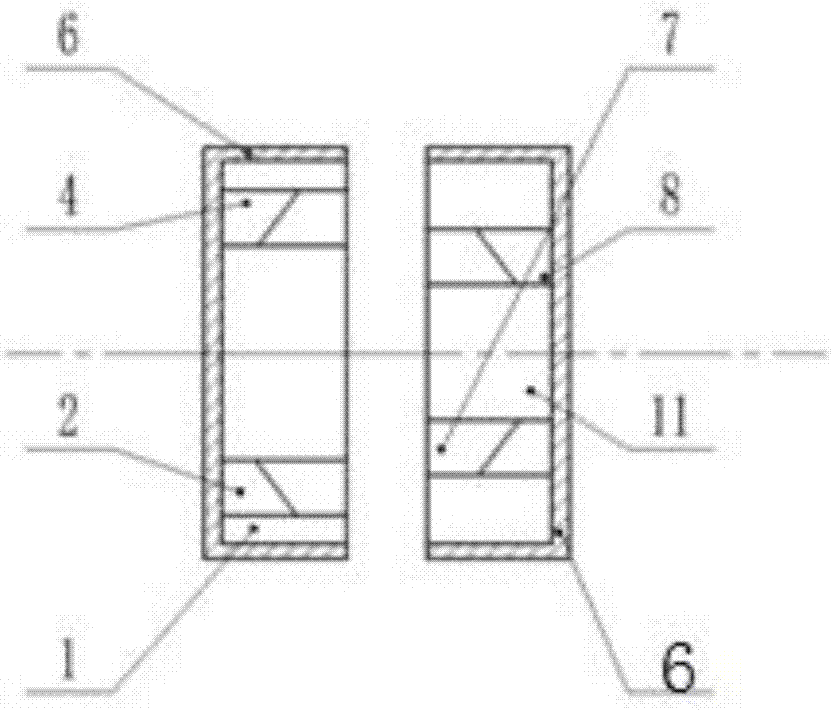

[0019] see Figure 1-Figure 4 , a non-contact electromagnetic brake, including a fixed plate 1, a moving plate 11, a fixed plate electromagnet and a moving plate electromagnet; The radian is provided with several mounting holes, and the fixed plate electromagnet is fixedly arranged in the mounting holes; the moving plate 11 is concentrically arranged on the side of the fixed plate 1 in parallel with the fixed plate 1, and there is a gap between the moving plate 11 and the fixed plate 1; The mounting holes corresponding to the fixed plate 1 are arranged on the plate 11, and the moving plate electromagnets are fixedly arranged in the mounting holes; The pole direction of the moving disk electromagnet facing the fixed disk 1 side on the disk 11 is arranged alternately, and the pole direction of the moving disk electromagnet facing the fixed disk 1 side can be changed to ensure the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com