FCT probe testing instrument

A technology of testing instruments and probes, which is applied in the testing field, can solve the problems of reducing detection efficiency, immovability, time-consuming and labor-intensive, etc., and achieve the effects of improving detection efficiency, reducing detection cost, and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

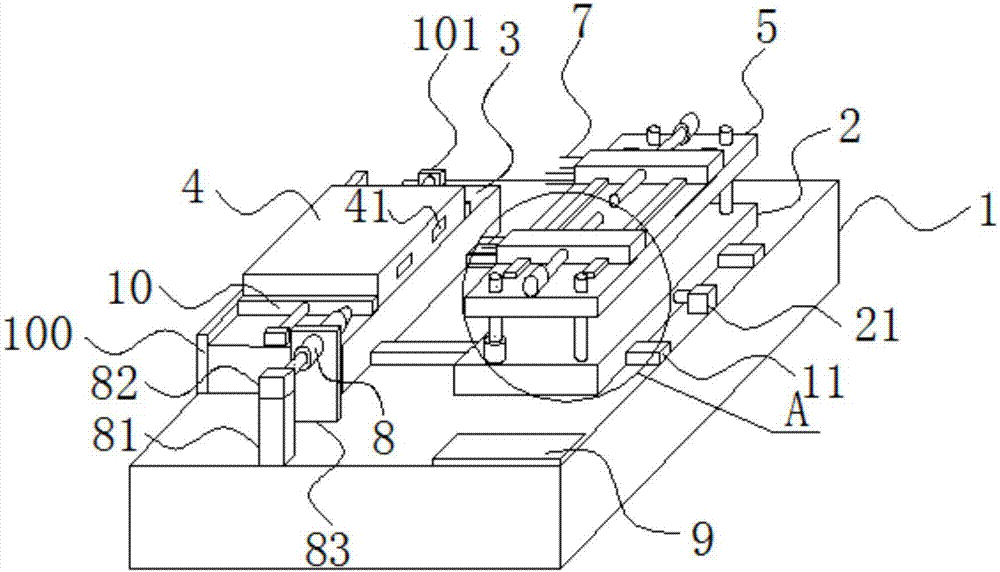

[0031] Embodiment: a kind of FCT probe test instrument, as Figure 1-Figure 4 As shown, it includes a control box 1, a movable plate 2 and a carrier plate 3, the carrier plate 3 and the movable plate 2 are all located above the control box 1, and the movable plate 2 and the carrier plate 3 are respectively Located on opposite sides of the upper surface of the control box 1;

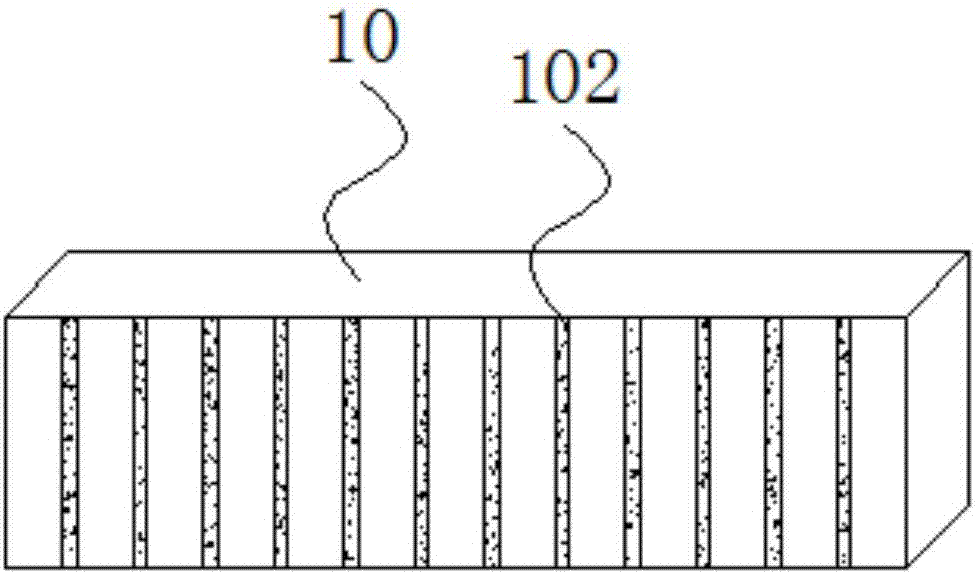

[0032] Two left and right positioning blocks 10 matching the left and right sides of the ECU box 4 are arranged on the top of the carrier plate 3, and the two positioning blocks 10 are close to or far away from each other by a clamping drive mechanism to clamp or loosen. Open the ECU box 4;

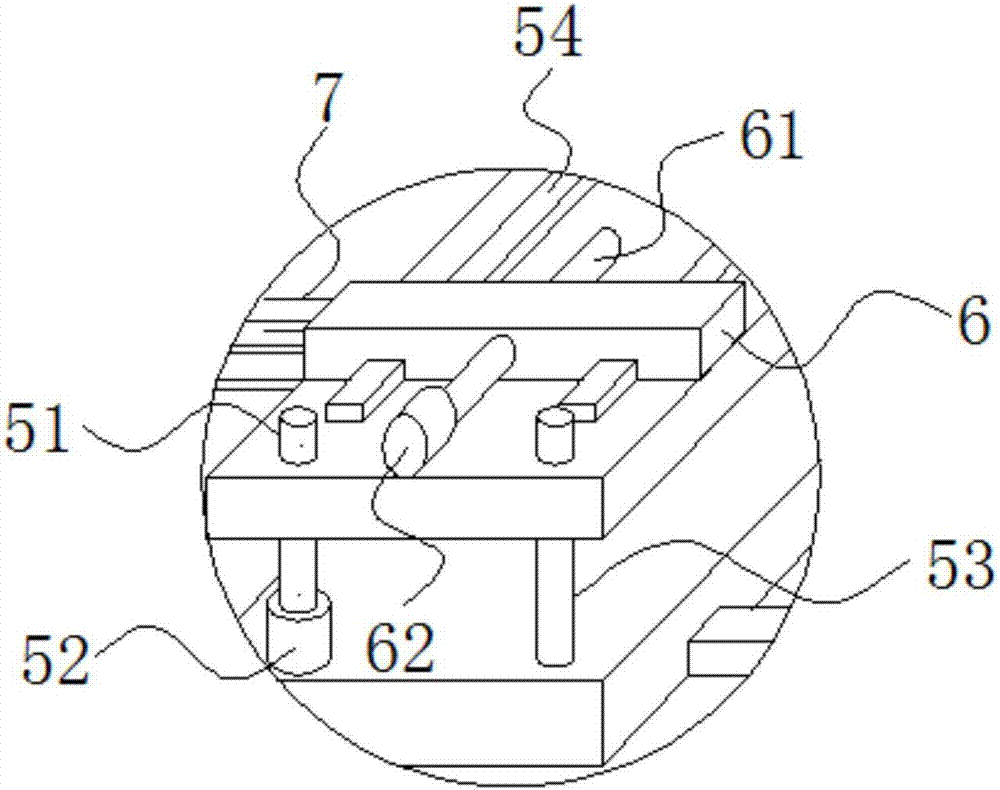

[0033] The direction of the movable plate 2 relative to the carrier plate 3 is defined as the front, the movable plate 2 is provided with a moving drive mechanism that drives it to move back and forth, the top of the movable plate 2 is provided with a needle plate 5, the The left and right sides of the needle plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com