Water-diversion-type, water-tower-type, vertical-type and continuous-type hydroelectric power generation mode

A technology of water towers and water diversion pipes, which is applied in the directions of hydropower generation, engine components, machines/engines, etc., can solve the problems of low power generation, high cost, affecting fish migration, etc., and achieve the effect of reducing investment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

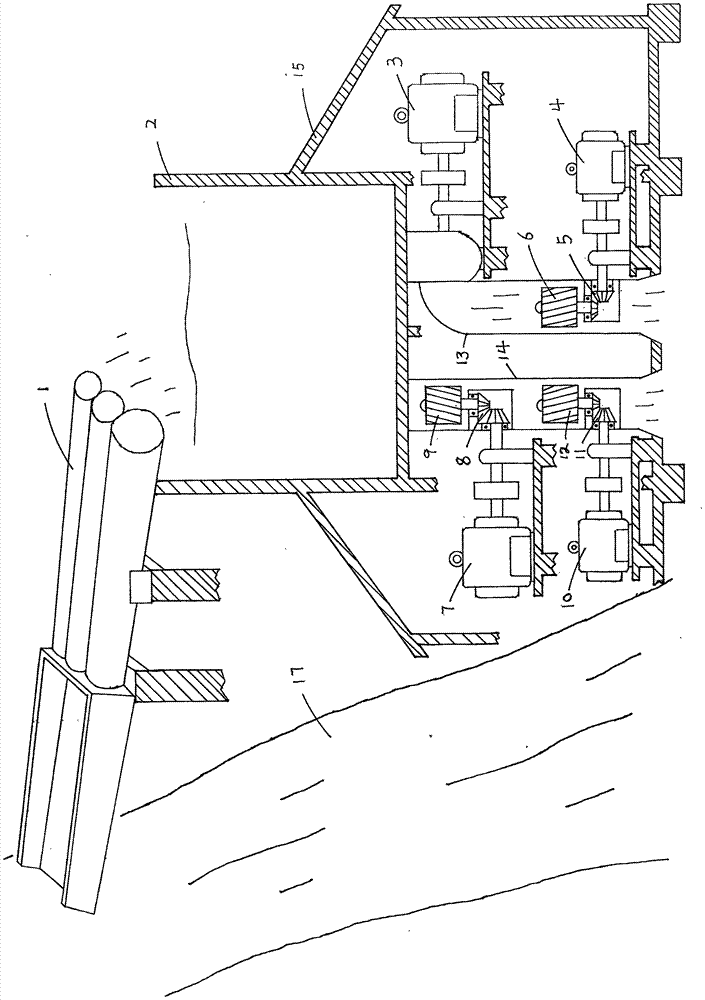

[0015] Water diversion, water tower, vertical, continuous hydroelectric power generation, including canal and water diversion pipe (1), diverting water from river (17) to water tower (2), there is a vertical circular hole power generation channel (13) at the bottom of the water tower in Erfang (15) ), the inside directly installs the mixed-flow hydroelectric generating set (3), and the bottom is the shaft-through water turbine (6), which drives the bevel gear drive (5), drives the shaft-through generating set (4), and realizes the continuous installation of the generating set up and down. A shaft-through water turbine (9) is installed vertically and directly in the round hole power generation channel (14), which drives the bevel gear transmission (8) and drives the generator set (7). (11), drives generator set (10), realizes generator set is installed continuously up and down. The diversion length is 50 meters, the height of the water tower is 5 meters, and the length and widt...

Embodiment 2

[0017] Embodiment 2 is basically the same as Embodiment 1, except that the length of water diversion is 2000 meters, the height of the water tower is 15 meters, and the length and width of the water tower are 15 meters. Larger generator sets and more circular hole power generation channels can be installed.

Embodiment 3

[0019] Embodiment 3 is basically the same as Embodiment 2, except that the length of water diversion is 4000 meters, the height of the water tower is 30 meters, the length and width of the water tower are 30 meters, larger generator sets can be installed, and more circular hole power generation channels can be installed.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length and width | aaaaa | aaaaa |

| Length and width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com