A method and system for preparing pulp using grass straw as raw material

A technology of grasses and straws, which is applied in the field of pulp preparation, can solve the problems of impossible extraction of lignin and five-carbon sugar, reduction of pulp whiteness, and increase of pulping cost, so as to reduce pollutant discharge, low processing temperature, The effect of ensuring whiteness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

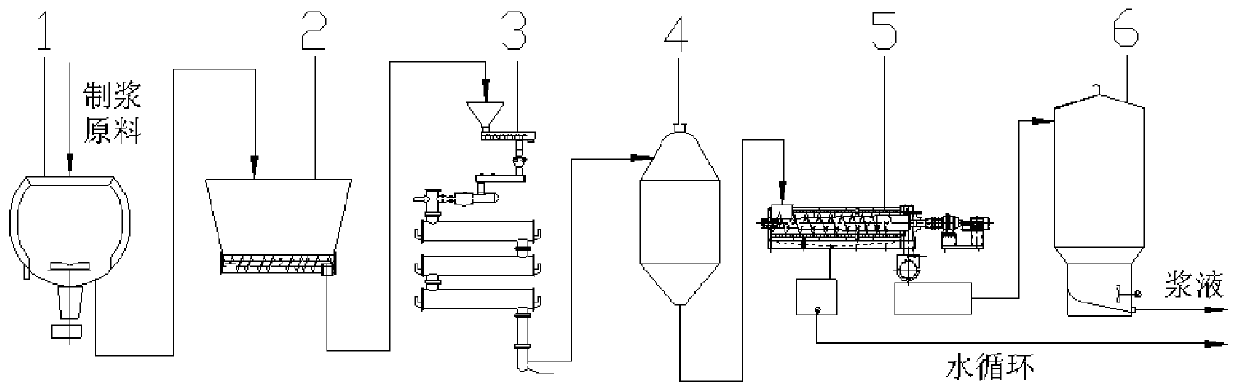

Image

Examples

Embodiment 1

[0044] 1. Pretreatment

[0045] Cutting the rice straws bundled into a round or square shape (i.e. pulping raw materials with a moisture content of 10-14%) so that the length of more than 80% of the cut rice straws is less than 25 mm; subsequently, removing the rice straws Sand, dust, leaves with low cellulose content, ears and other impurities in the rice straw to obtain pretreated rice straw.

[0046] 2. The first enzymatic treatment

[0047] Mix the pretreated rice straw and water according to the mass ratio of 1:6, adjust the pH value of the mixture to about 6, and raise the temperature to about 40°C, keep it warm, and then add laccase with an enzyme activity of 10000U / g for the second step. 1. Enzyme hydrolysis treatment, wherein the dosage of laccase is 0.1% (that is, 0.1kg laccase is used for 100kg of pretreated rice straw and water mixture); after about 2 hours of the first enzymolysis treatment, the first enzymolysis treatment product is obtained.

[0048] The ligni...

Embodiment 2

[0059] 1. Pretreatment

[0060] Cut the wheat straw (moisture content 12%), so that the length of more than 80% of the wheat straw after cutting is less than 25mm; then, remove impurities such as sand, dust, and leaves with low cellulose content in the wheat straw , to obtain pretreated wheat straw.

[0061] 2. The first enzymatic treatment

[0062] Mix the pretreated wheat straw and water according to the mass ratio of 1:6, adjust the pH value of the mixture to about 5, and raise the temperature to about 50°C, keep it warm, and then add laccase with an enzyme activity of 10000U / g for the second step. 1. Enzymatic hydrolysis treatment, wherein the dosage of laccase is 0.05%; about 2 hours after the first enzymatic hydrolysis treatment, the product of the first enzymatic hydrolysis treatment is obtained; after the first enzymolysis treatment, the dissolution rate of lignin is 73%, The dissolution rate of pentosan was 40%.

[0063] 3. Cooking treatment

[0064] Add sodium hy...

Embodiment 3

[0071] 1. Pretreatment

[0072] Cut the straw straw (moisture content is about 12%), so that the length of more than 80% of the straw straw after cutting is less than 25mm; then, remove sand, dust, and leaves with low cellulose content in the straw straw and other impurities to obtain pretreated rice straw.

[0073] 2. The first enzymatic treatment

[0074] Mix the pretreated rice straw and water according to the mass ratio of 1:8, adjust the pH value of the mixture to about 7, and raise the temperature to about 60°C, keep it warm, and then add laccase with an enzyme activity of 10000U / g for the second step. 1. Enzymolysis treatment, wherein the amount of laccase is 0.2%; after about 1 hour of the first enzymolysis treatment, the product of the first enzymolysis treatment is obtained; after the first enzymolysis treatment, the dissolution rate of lignin is 58%, The dissolution rate of pentosan was 40%.

[0075] 3. Cooking treatment

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com