Rotary solid material fermentation device

A technology of a solid material and a fermentation device, applied in the field of fermentation, can solve the problems that the stirring equipment cannot achieve the stirring effect, the free water cannot be dispersed and removed in time, and the fermentation quality of the material is affected, so as to improve the drying efficiency and fermentation quality, and the drying effect is good. , the effect of improving drying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in detail below in conjunction with the embodiments, so that those skilled in the art can implement it with reference to the description.

[0030] It should be understood that terms such as "having", "comprising" and "including" as used herein do not denote the presence or addition of one or more other elements or combinations thereof.

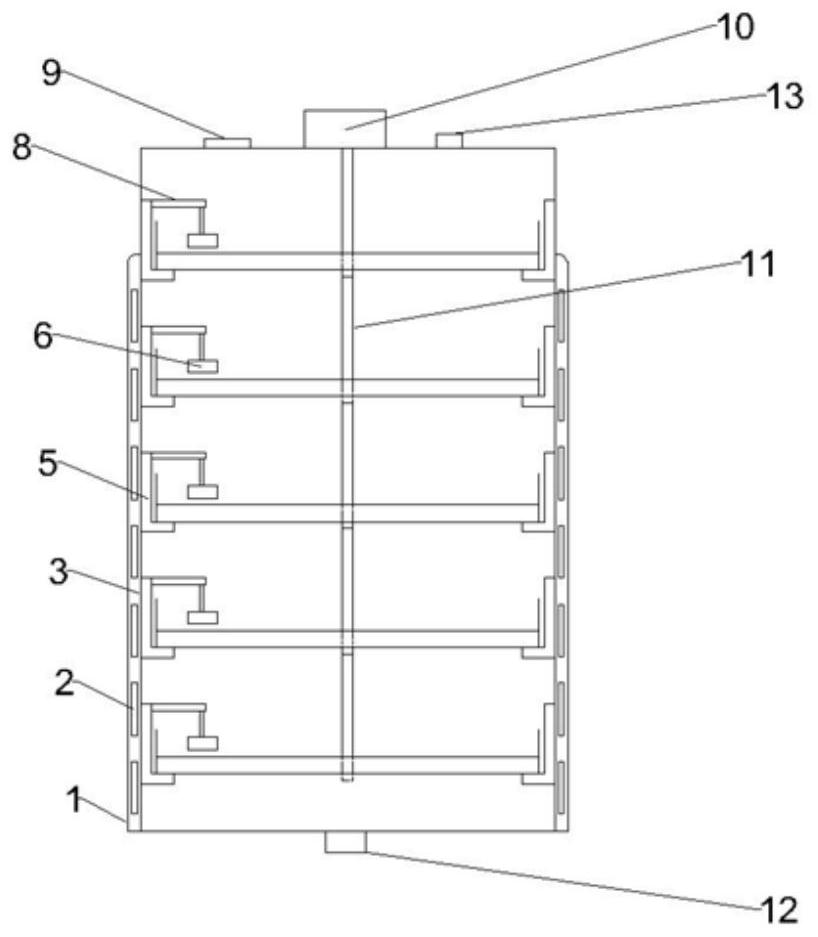

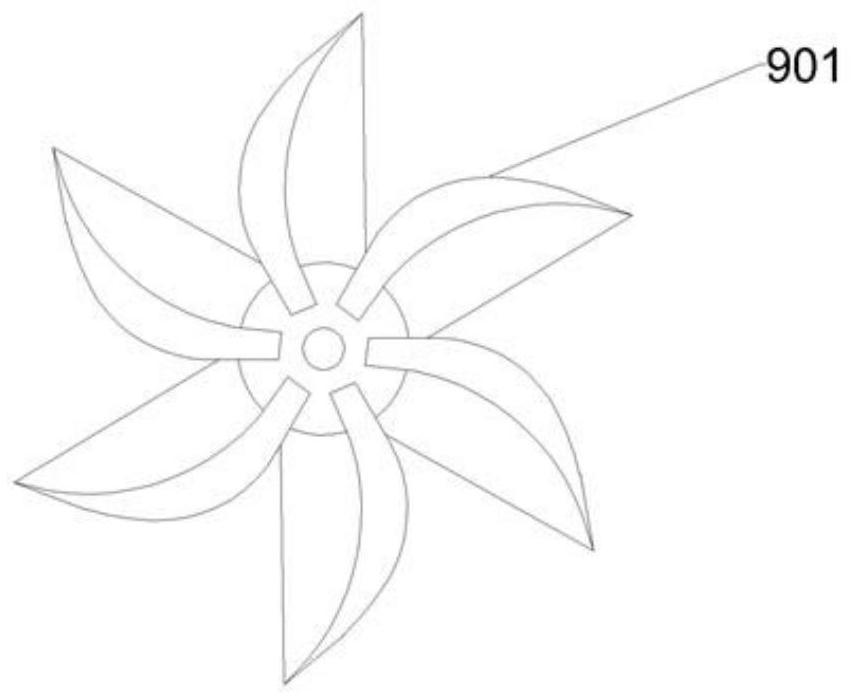

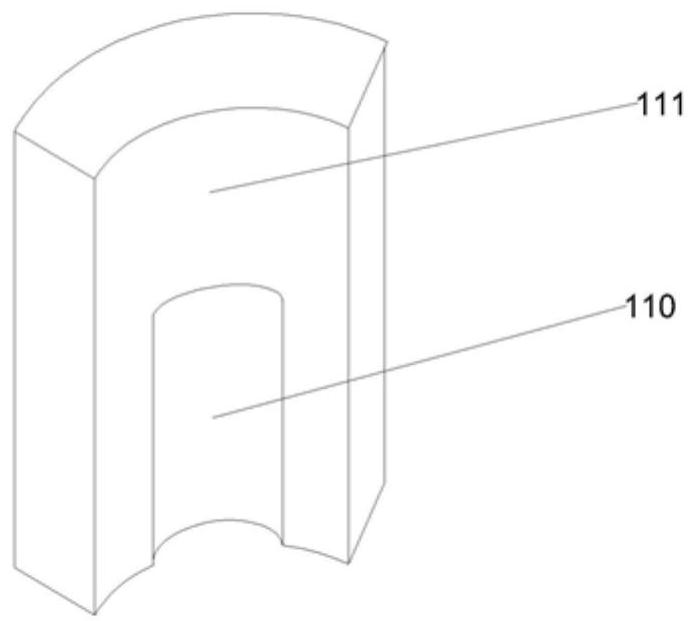

[0031] Such as figure 1 , 2 , Shown in 3, 4, a kind of rotary solid material fermenting device comprises:

[0032] Housing 3, the top of the housing 3 is provided with a feed port 9 and an exhaust port 13, and the bottom of the housing 3 is provided with a discharge port 12, wherein the outer wall of the housing 3 is provided with a thermal insulation cover 1 , a heat preservation chamber is formed between the housing 3 and the heat preservation cover 1, and a plurality of heating plates 2 are arranged at intervals in the heat preservation chamber;

[0033] Motor 10, which is fixed on t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com