High-temperature-resistant auxiliary steam-driven oil-displacing agent for thermal oil recovery and application thereof

An auxiliary steam and thermal oil recovery technology, applied in the field of high temperature resistant auxiliary steam flooding oil displacement agent and surfactant for thermal oil recovery, to achieve good oil displacement effect and high recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

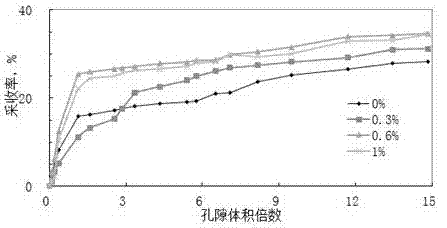

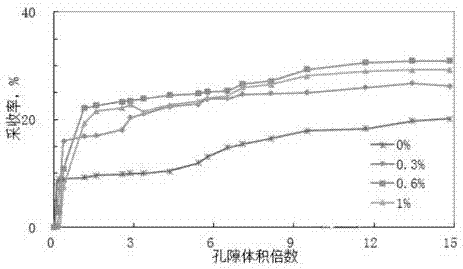

Image

Examples

Embodiment 1

[0026] Embodiment 1 A kind of high temperature resistant auxiliary steam flooding oil displacement agent for thermal oil recovery

[0027] Preparation method: mix a mixture of N-methylolacrylamide, dimethylaminoethyl acrylate, and 3-acrylamido-3-methylbutyrate sodium (number ratios are 300,000, 20,000, and 120,000) with complexing agent ethylene glycol The high temperature resistant oil displacement agent can be obtained by performing mixed copolymerization reaction of amine tetraacetic acid di, co-solvent urea, solubilizer sodium lauryl sulfate and redox-azo water-soluble composite initiator.

[0028] The obtained oil displacement agent is composed of structural units of the following formulas (I), (II), and (III);

[0029]

[0030]

[0031] Wherein, M in the formula (III) is a sodium ion; the number of structural units in the formulas (I), (II), and (III) is 300,000, 20,000 and 120,000.

Embodiment 2

[0032] Embodiment 2 A high temperature resistant auxiliary steam flooding oil displacement agent for thermal oil recovery

[0033] The difference between the preparation method and Example 1 is that the quantity ratios of N-methylolacrylamide, dimethylaminoethyl acrylate and 3-acrylamido-3-methylbutyrate are 100000, 40000 and 80000; other same Embodiment 1;

[0034] The oil displacement agent that obtains is connected by the structural unit of formula (I), (II), (III) and forms (with embodiment 1); Wherein, M is potassium ion in formula (III); Formula (I), (II) , The number of structural units of (Ⅲ) is 100000, 40000 and 80000, and others are the same as in Example 1.

Embodiment 3

[0035] Embodiment 3 A kind of high temperature resistant auxiliary steam flooding oil displacement agent for thermal oil recovery

[0036] The difference between the preparation method and Example 1 is that the quantity ratios of N-methylolacrylamide, dimethylaminoethyl acrylate, and 3-acrylamido-3-methylbutyrate are 500,000, 2,000, and 250,000; Embodiment 1;

[0037] The oil displacement agent that obtains is connected by the structural unit of formula (I), (II), (III) and forms (with embodiment 1); Wherein, M is ammonium ion in formula (III); Formula (I), (II) ), (Ⅲ) the number of structural units is 500000, 2000 and 250000, other with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com