Liquid water-retaining agent and preparation method thereof

A water-retaining agent and liquid technology, applied in the agricultural field, can solve the problems of unfavorable mechanized farming, inability to mix the water-retaining agent with the soil, poor water-retaining effect, etc., and achieve good water-absorbing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

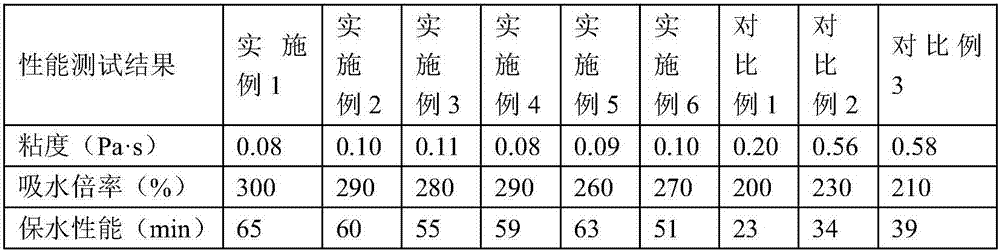

Examples

Embodiment 1

[0025] S1: Add 210kg of acrylic acid to 425kg of water and mix evenly, then add sodium hydroxide to the reaction system to adjust the pH of the reaction system to 5.5, wherein the concentration of acrylic acid is 0.6g / L, and the concentration of sodium hydroxide is 0.7g / L;

[0026] S2: Raise the temperature of the reaction system to 63°C, add 5kg of sodium persulfate, 2kg of N,N-dimethylacrylamide, and 4kg of N,N-methylenebisacrylamide to the reaction system, and the reaction time is 70min. After the reaction, add hydrochloric acid to adjust the pH of the reaction system to 7.1 in the reaction system, wherein the concentration of hydrochloric acid is 0.2g / L;

[0027] S3: Raise the temperature of the reaction system to 72° C., add 10 kg of sodium sulfate and 65 kg of modified silicone resin to the reaction system, and react for 30 minutes. After the reaction is completed, a liquid water retaining agent is obtained.

Embodiment 2

[0029] S1: Add 200 kg of acrylic acid to 400 kg of water and mix evenly, then add sodium hydroxide to the reaction system to adjust the pH of the reaction system to 5.1, wherein the concentration of acrylic acid is 0.7 g / L, and the concentration of sodium hydroxide is 0.9 g / L;

[0030] S2: Raise the temperature of the reaction system to 60°C, add 5kg of potassium disulfate, 3kg of N,N-dimethylacrylamide, and 2kg of N,N-methylenebisacrylamide to the reaction system, and the reaction time is 60min. After the reaction, add hydrochloric acid to the reaction system to adjust the pH of the reaction system to 6.8, wherein the concentration of hydrochloric acid is 0.1g / L;

[0031] S3: Raise the temperature of the reaction system to 74°C again, add 6 kg of sodium sulfide, 6 kg of sodium sulfate, and 60 kg of modified silicone resin to the reaction system, and react for 30 minutes. After the reaction is completed, a liquid water retaining agent is obtained.

Embodiment 3

[0033] S1: Add 220 kg of acrylic acid to 400 kg of water and mix evenly, then add sodium hydroxide to the reaction system to adjust the pH of the reaction system to 5.1, wherein the concentration of acrylic acid is 0.7 g / L, and the concentration of sodium hydroxide is 0.5 g / L;

[0034] S2: Raise the temperature of the reaction system to 66°C, add 9kg of hydrogen peroxide, 3kg of N,N-dimethylacrylamide, and 2kg of N,N-methylenebisacrylamide to the reaction system, and the reaction time is 80min. After the reaction, add hydrochloric acid to the reaction system to adjust the pH of the reaction system to 6.8, wherein the concentration of hydrochloric acid is 0.1g / L;

[0035] S3: Raise the temperature of the reaction system to 74° C., add 8 kg of sodium sulfate and 70 kg of modified silicone resin to the reaction system, and react for 40 minutes. After the reaction is completed, a liquid water retaining agent is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com