Separation method for propane dehydrogenation reaction gas

A propane dehydrogenation and separation method technology, which is applied in the purification/separation of hydrocarbons, chemical instruments and methods, hydrocarbons, etc., can solve the problems of poor separation effect and high energy consumption, and reduce investment and energy consumption. The effect of low consumption and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

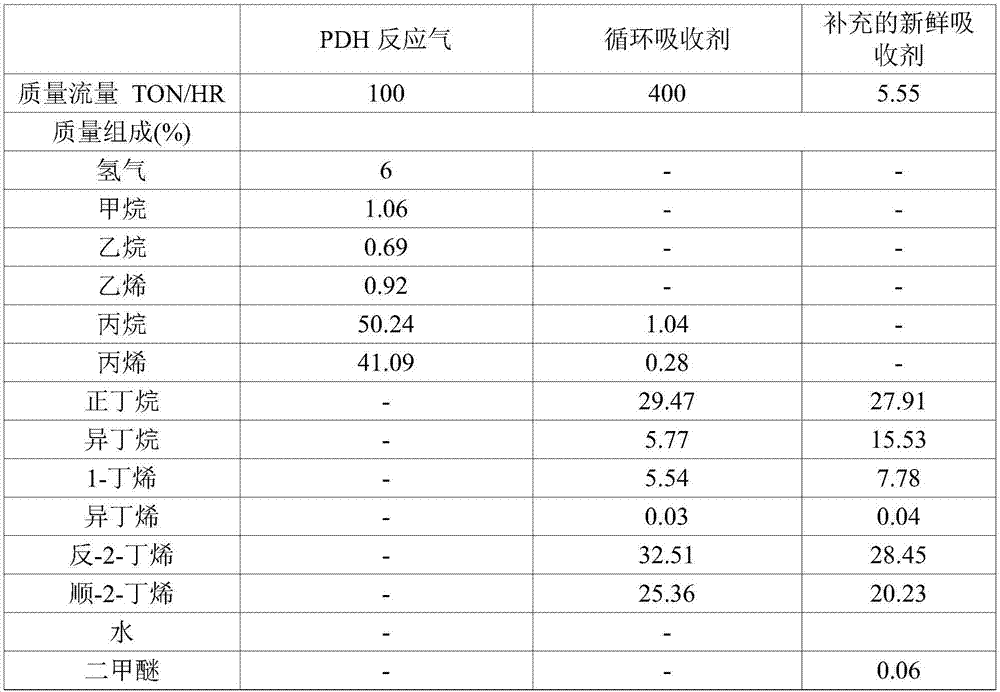

[0059] This embodiment is used to illustrate the separation method of the propane dehydrogenation reaction gas of the present invention.

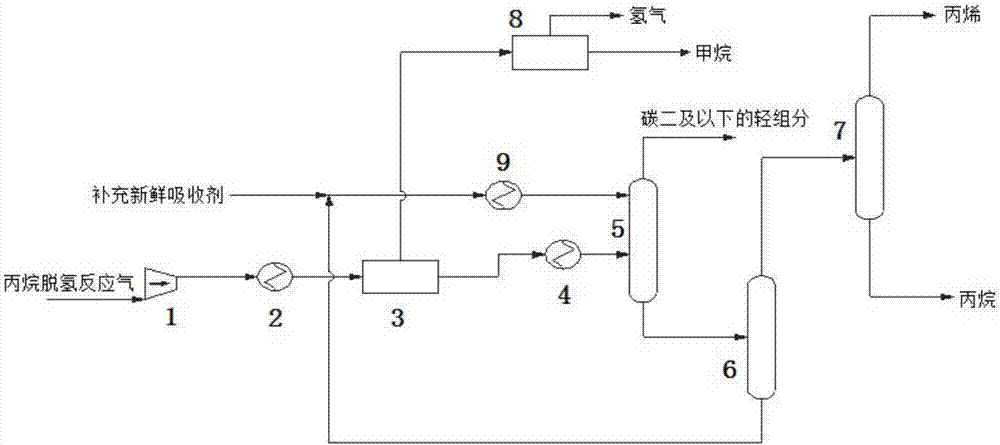

[0060] (1) if figure 1 Said, the PDH gas from the outlet of the PDH reactor (see Table 1 below for its specific composition) is compressed to 2MPa through a compressor 1 with three compression sections, and then passed into the first cooler 2 to cool to 20°C;

[0061] (2) passing the cooled gas into the membrane separation system 3 and carrying out membrane separation at an operating pressure of 2 MPa to obtain permeate gas containing methane and hydrogen and non-permeate gas rich in hydrocarbons;

[0062] (3) Pass the above-mentioned hydrocarbon-rich non-permeate gas into the second cooler 4 to cool to 15° C., and pass the above-mentioned permeate gas containing methane and hydrogen into the pressure swing adsorption hydrogen production system 8 for pressure swing adsorption production. Hydrogen, wherein the conditions for producing hydro...

Embodiment 2

[0070] This embodiment is used to illustrate the separation method of the propane dehydrogenation reaction gas of the present invention.

[0071] (1) if figure 1 As stated, the PDH gas from the outlet of the PDH reactor (see Table 2 below for its specific composition) is compressed to 3.0 MPa by a compressor 1 with three compression sections, and then passed into the first cooler 2 to cool to 30°C;

[0072] (2) Pass the cooled gas into the membrane separation system 3 and carry out membrane separation at an operating pressure of 3.0 MPa to obtain permeate gas containing methane and hydrogen and non-permeate gas rich in hydrocarbons;

[0073] (3) Pass the above-mentioned hydrocarbon-rich non-permeate gas into the second cooler 4 to cool to 13° C., and pass the above-mentioned permeate gas containing methane and hydrogen into the pressure swing adsorption hydrogen production system 8 for pressure swing adsorption production. Hydrogen, wherein the conditions for producing hydrog...

Embodiment 3

[0082] This embodiment is used to illustrate the separation method of the propane dehydrogenation reaction gas of the present invention.

[0083] (1) if figure 1 Said, the PDH gas from the outlet of the PDH reactor (see Table 3 below for its specific composition) is compressed to 2MPa by a compressor 1 with three compression sections, and then passed into the first cooler 2 to cool to 15°C;

[0084] (2) passing the cooled gas into the membrane separation system 3 and performing membrane separation at an operating pressure of 1.5 MPa to obtain permeate gas containing methane and hydrogen and non-permeate gas rich in hydrocarbons;

[0085] (3) Pass the above-mentioned hydrocarbon-rich non-permeate gas into the second cooler 4 to cool to 15° C., and pass the above-mentioned permeate gas containing methane and hydrogen into the pressure swing adsorption hydrogen production system 8 for pressure swing adsorption production. Hydrogen, wherein the conditions for producing hydrogen b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com