Sewage treatment system with ultrafiltration structure

A sewage treatment system and filter mechanism technology, applied in water/sewage treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve the problems of poor filtering effect, easy clogging and hardening of filter elements, etc. , to improve the filtering effect, prevent clogging and solve the clogging effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

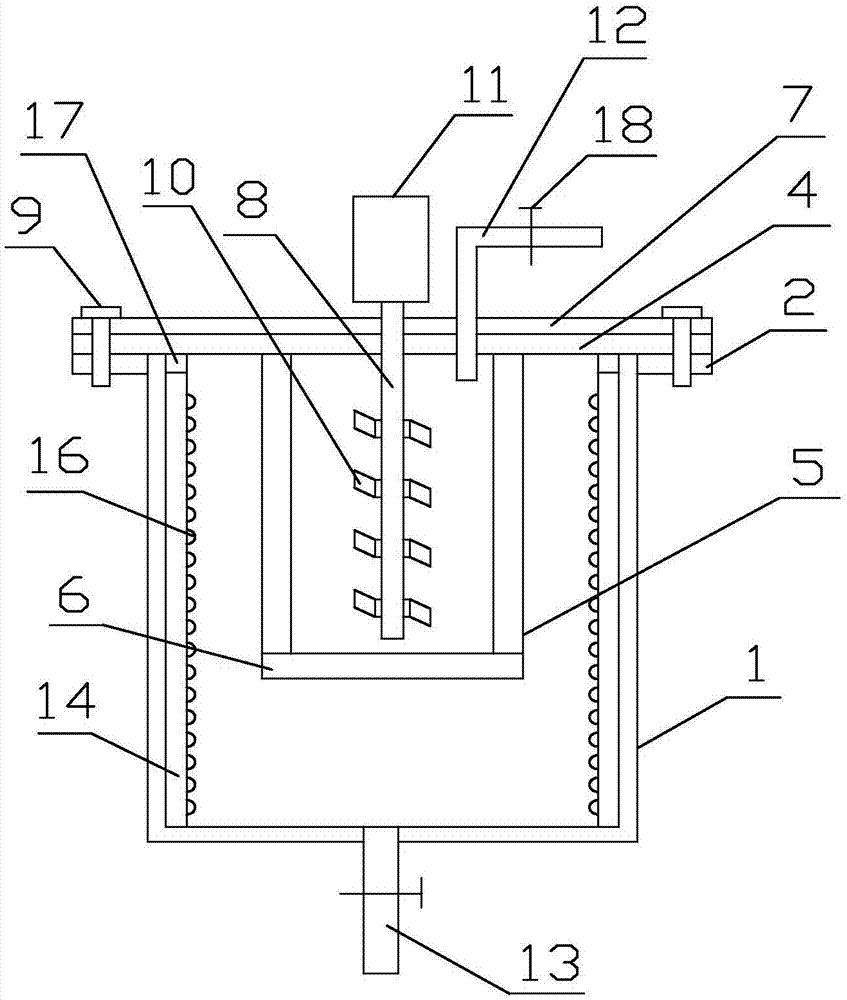

[0024] Such as figure 1 and figure 2 As shown, the sewage treatment system with ultrafiltration structure of the present invention includes a vertical cylinder 1, the bottom of the cylinder 1 is closed, the top is open, and the side wall of the open end of the cylinder 1 along the axis The ring is provided with a mounting flange 2; it also includes a filter mechanism and a stirring mechanism, and the filter mechanism includes an installation top plate 4, a filter cartridge 5 and an installation bottom plate 6, and the filter cartridge 5 is arranged between the installation top plate 4 and the installation bottom plate 6 , the filter cartridge 5 is set on the ultrafiltration membrane, the installation top plate 4 is set on the open end of the cylinder body 1, and the filter cartridge 5 is placed in the cylinder body 1; the stirring mechanism includes a mounting base plate 7 and a stirring shaft 8 , the bolts 9 sequentially pass through the installation base plate 7, the insta...

Embodiment 2

[0026] As a further improvement on the basis of Example 1, the stirring blade 10 is provided with a filter bag 14 . An auxiliary sleeve 15 is sleeved inside the cylinder 1 , the outer wall of the auxiliary sleeve 15 is in contact with the inner wall of the cylinder 1 , and several protrusions 16 are arranged on the inner wall of the auxiliary sleeve 15 . The axial bottom end of the auxiliary sleeve 15 is in contact with the inner bottom wall of the cylinder body 1, and a sealing rubber ring 17 is arranged on the edge of the axial top port along the circumferential ring, and the lower surface of the installation top plate 4 is transition-fitted with the sealing rubber ring 17. Tight fix.

Embodiment 3

[0028] As a further improvement on the basis of Embodiment 2, a water flow control valve 18 is provided on the water inlet pipe 12 and the water discharge pipe 13 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com