Titanium-based amorphous/titanium alloy layered composite material and preparation method thereof

A technology of layered composite materials and amorphous alloys, applied in the direction of metal layered products, chemical instruments and methods, lamination, etc., can solve the problem of difficulty in preparing prefabricated bodies with regular layer and layer arrangement, unfavorable mechanical properties of composite materials, Unable to obtain multi-layer composite materials and other problems, to achieve good chemical compatibility, good physical compatibility, and good interface bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Prepare 100g of titanium-based master alloy by using arc melting equipment, the composition is: Ti 32.8 Zr 30.2 Ni 5.3 Cu 9 be 22.7 (atomic percent), and then the master alloy was prepared into an amorphous strip of 10 mm×50 μm (width×thickness) in a single-roller stripping device. Cut the amorphous strips to a length of 50 mm, stack them alternately with pure titanium strips (purity greater than 99%), and clamp them in a device to obtain a titanium-based amorphous / pure titanium preform. After vacuum packaging, heating and water quenching, a composite material sample with a size of 50mm×10mm×6.5mm (length×width×thickness) was obtained.

[0046] The process parameters are as follows:

[0047] Vacuum degree: 2×10 -3 Pa;

[0048] Insulation temperature: 865°C;

[0049] Heat preservation time: 180s.

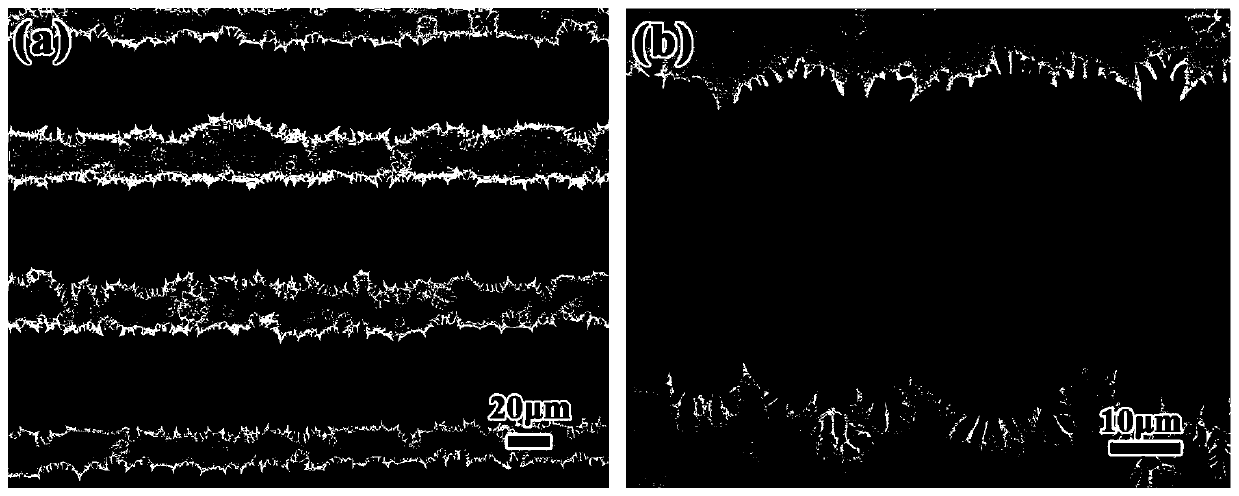

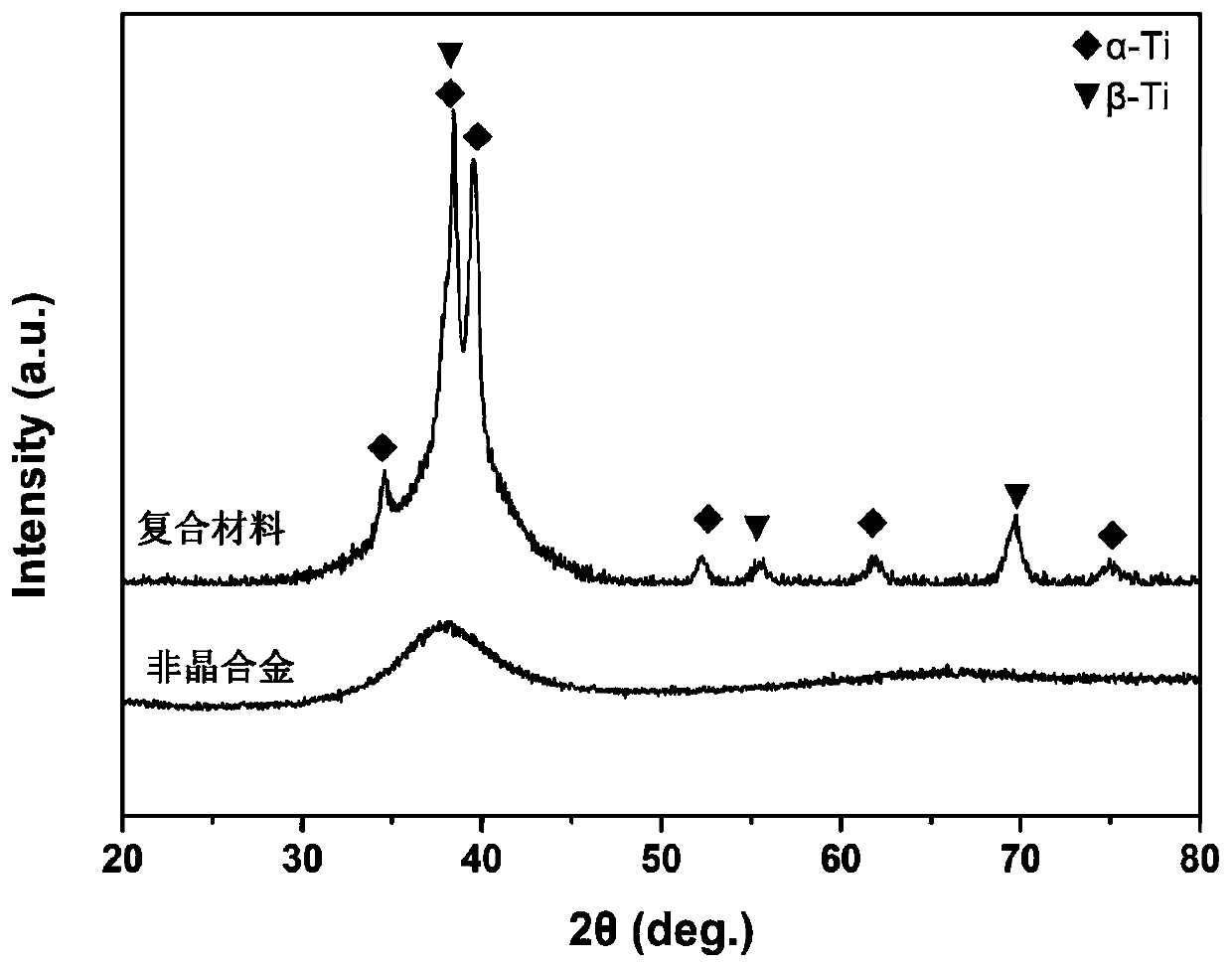

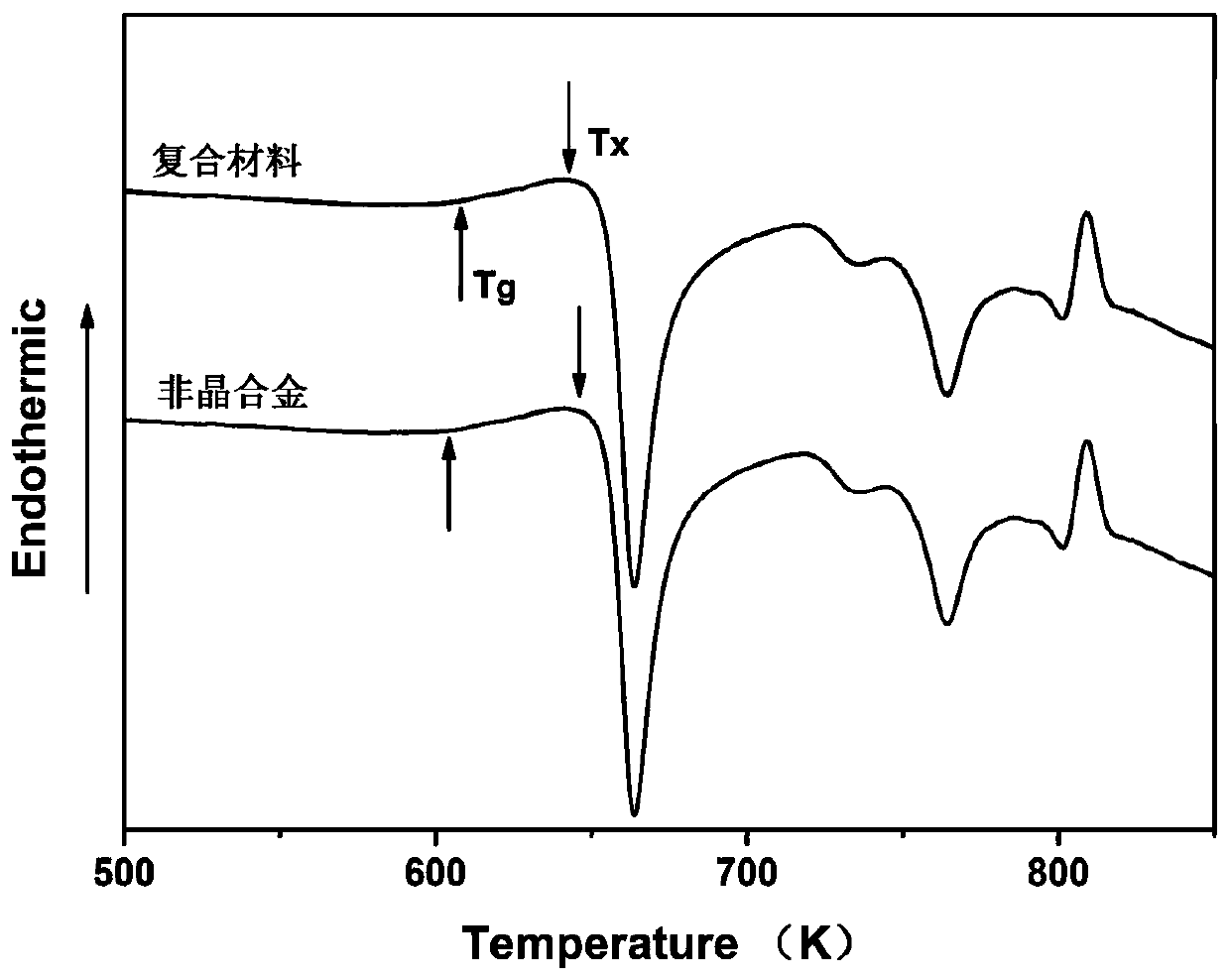

[0050] The microstructure of the composite material is as follows figure 1 As shown, the amorphous phase and Ti are uniformly distributed, and no defects such as hol...

Embodiment 2

[0053] The difference from Example 1 is that the composition of the titanium-based amorphous alloy strip is specifically shown in Table 1, and the rest are the same as in Example 1.

[0054] Table 1 Titanium-based amorphous alloy strip composition

[0055]

[0056]

[0057] The microstructure of the prepared composite material was detected by XRD and SEM. The results showed that the composite material was composed of amorphous phase, α-Ti and β-Ti, and the titanium-based amorphous layer and titanium alloy layer were uniformly arranged, and the interface was free of Formation of defects such as holes.

Embodiment 3

[0059] The difference from Example 1 is that the composition of the titanium alloy strip is specifically shown in Table 2, and the rest are the same as in Example 1.

[0060] Table 2 Titanium alloy strip composition

[0061] serial number Composition (atomic percent) 1 Ti 75 Zr 23 Cu 2

[0062] Characterized by XRD, DSC and SEM detection means, the prepared composite material presents typical interphase distribution characteristics of amorphous layer and titanium alloy layer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com