A deep cavity component track crawling robot type automatic processing device and method

A technology of automatic processing and track crawling, which is applied in the direction of manipulators, manufacturing tools, program-controlled manipulators, etc., can solve the problems of insufficient rigidity of cantilever equipment, and achieve the effects of avoiding vertical axis conversion errors, improving rigidity, and improving machining accuracy and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The specific embodiments of the present invention will be described in detail below in conjunction with the technical solutions and accompanying drawings.

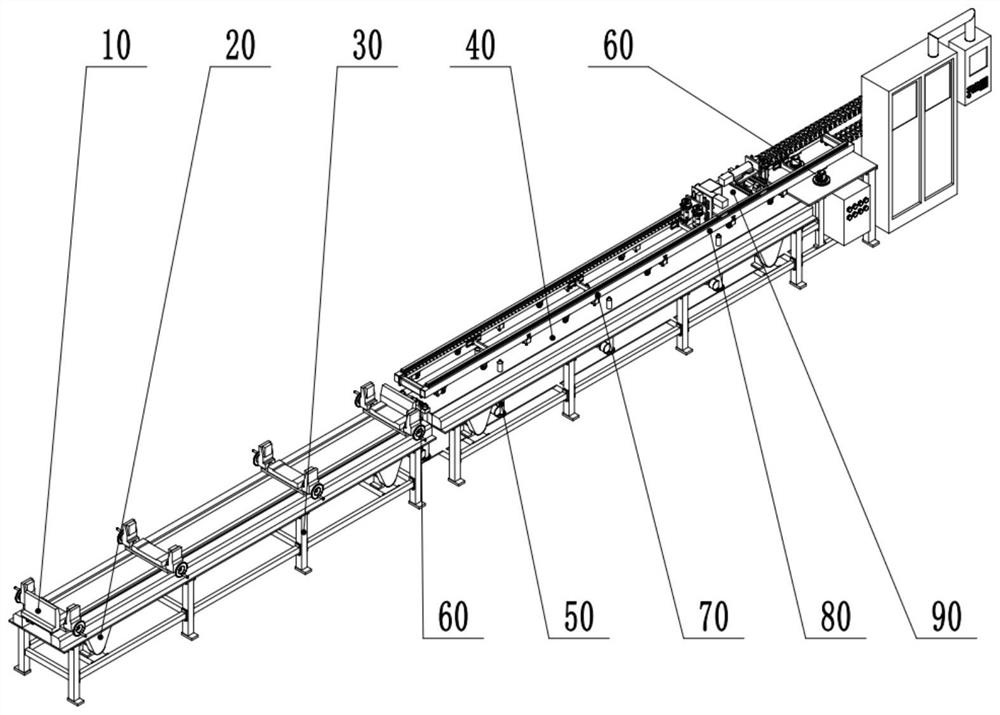

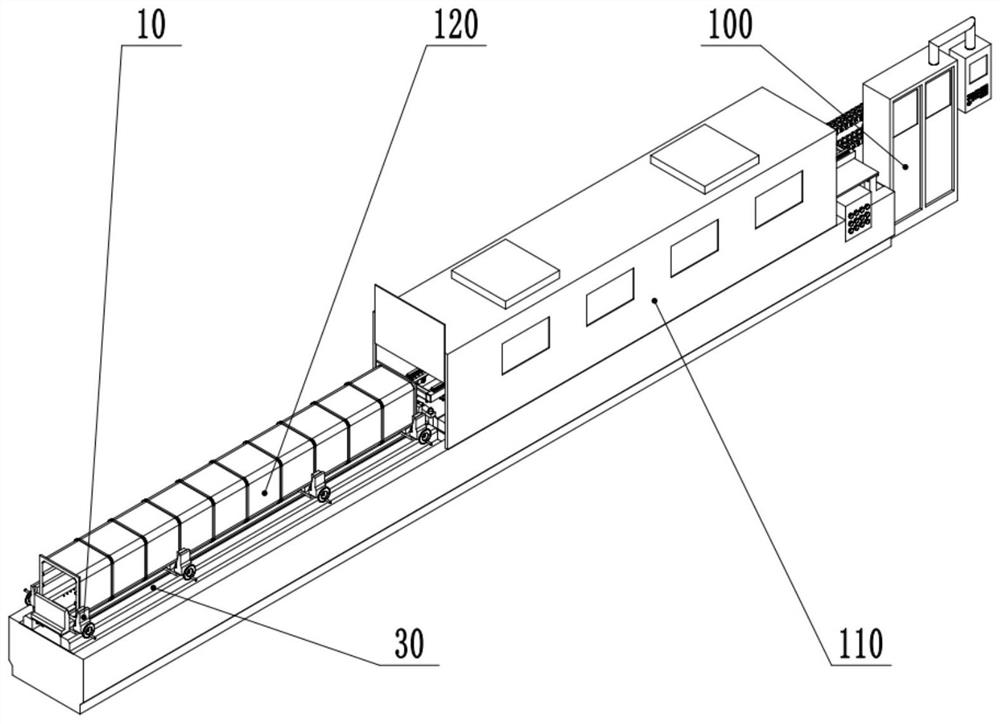

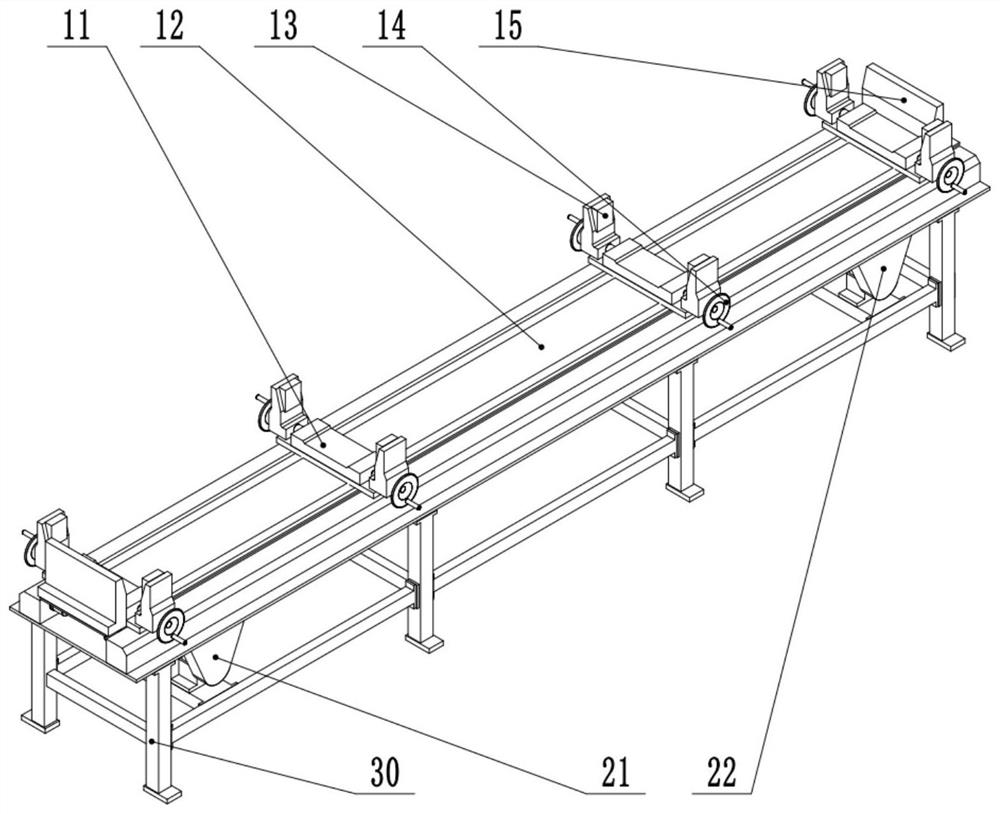

[0040] Such as Figure 1-5 As shown, a crawling robot-type automatic processing device for deep cavity components includes a clamping and positioning device 10, a conveying system 20, a clamping workbench 30, a processing workbench 40, a self-avoiding support system 50, and a guide rail positioning and lifting system 60. , a clamping system 70, a guide rail 80, a processing system 90 and a numerical control system 100; the deep cavity component is a component 120 with an aspect ratio greater than 2;

[0041] The clamping and positioning device 10 is installed on the conveying system 20, and the conveying system 20 is installed on the clamping workbench 30, and is connected with the numerical control system 100; the clamping workbench 30 is connected with the processing workbench 40, and through the foot Installed o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com