Multifunctional deburring equipment for aluminum alloy production

An aluminum alloy, multi-functional technology, applied in the direction of metal processing equipment, grinding/polishing equipment, grinding machine tool parts, etc., can solve problems such as single, no waste slag recovery structure, lack of protective structure and functions, etc., to achieve operation Convenient and quick, conducive to the deburring operation and the effect of protecting safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

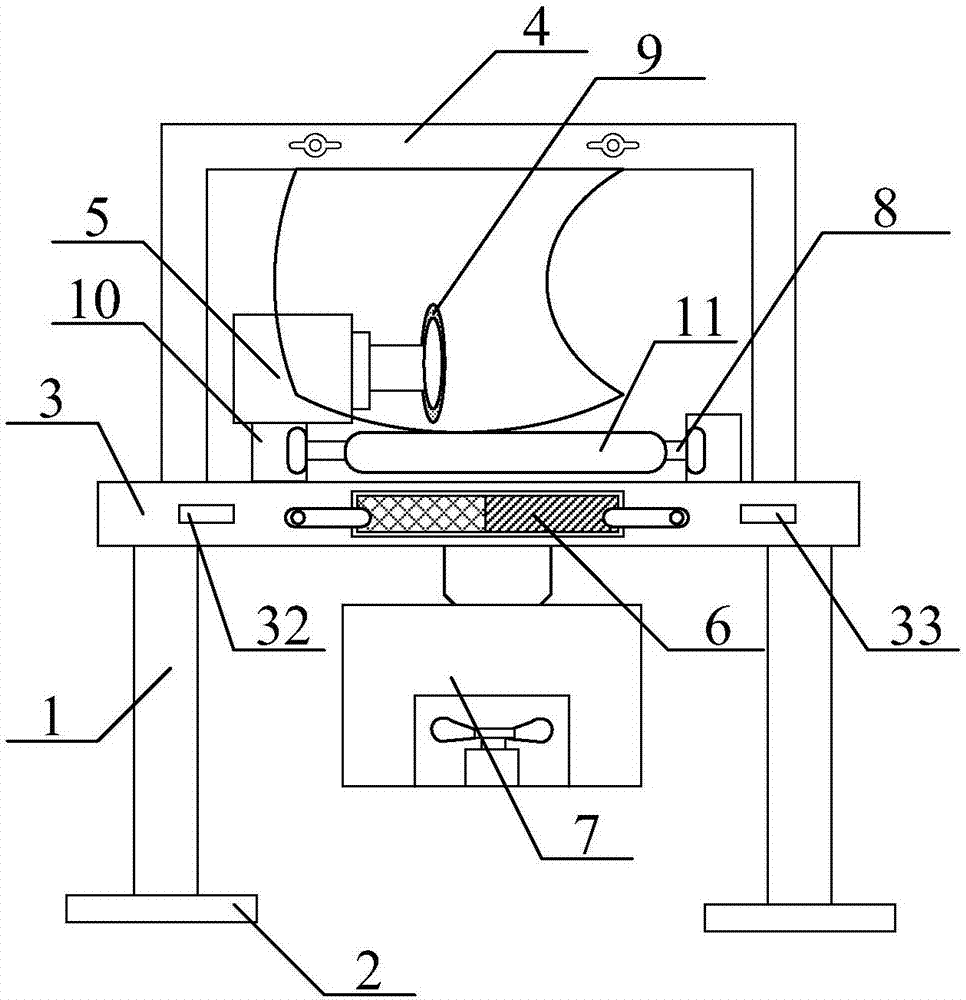

[0033] as attached figure 1 to attach Figure 4 shown

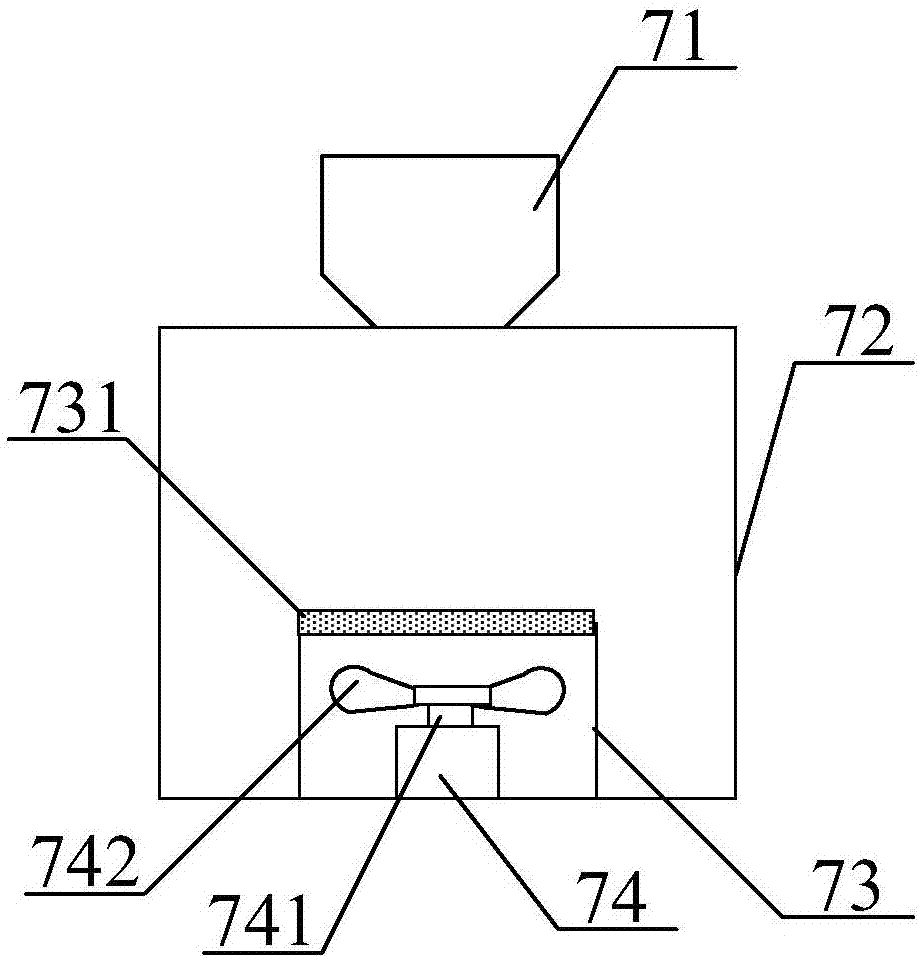

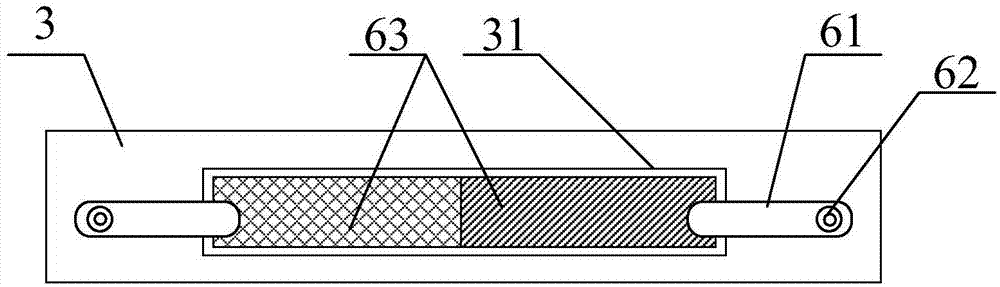

[0034] The present invention provides a multifunctional deburring equipment for aluminum alloy production, which includes a support column 1, a shock absorber 2, a workbench 3, a protective curtain structure 4, a motor 5, a polishing stone structure 6, a waste residue box structure 7, and a roller 8. The grinding wheel 9, the support block 10 and the cylinder 11, the support columns 1 are respectively bolted to the four corners of the lower surface of the workbench 3; the shock absorber 2 is bolted to the lower end of the support column 1; The protective curtain structure 4 is welded on the upper surface of the workbench 3; the motor 5 is bolted to the upper surface of the support block 10 provided on the left; the grinding stone structure 6 is clamped in the middle of the front surface of the workbench 3 position; the waste slag box structure 7 is bolted to the middle of the lower surface of the workbench 3; the roller...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com