Sleeve type component coiling classified circling device and method

A sleeve-type and grading technology, used in manufacturing tools, metal chains, metal processing equipment, etc., can solve the problems of uneven outer diameter dispersion, large and small heads, and poor roundness, and achieve good results, stable performance, and avoidance of hair pulling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with accompanying drawing and embodiment the present invention is described in further detail:

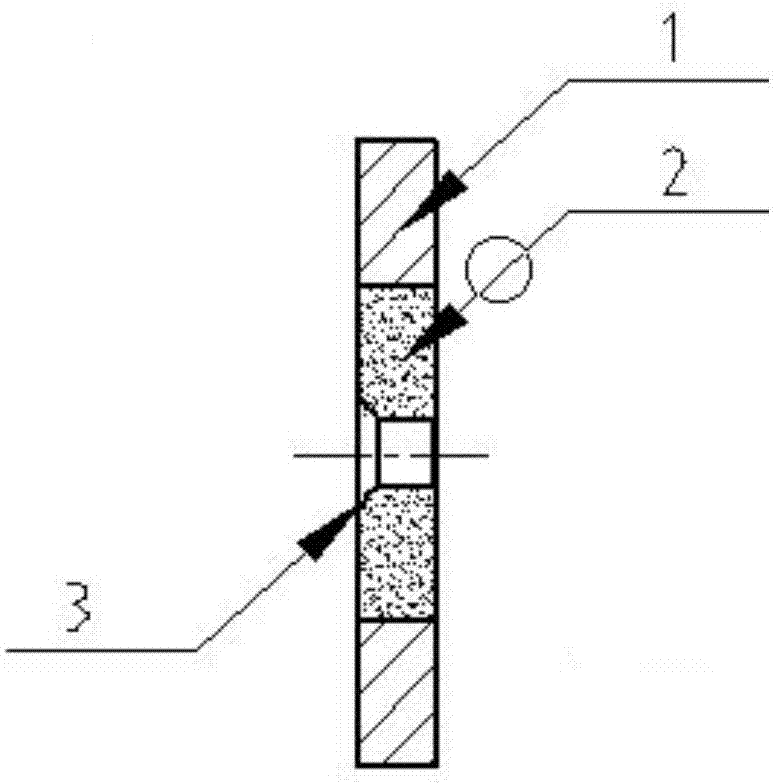

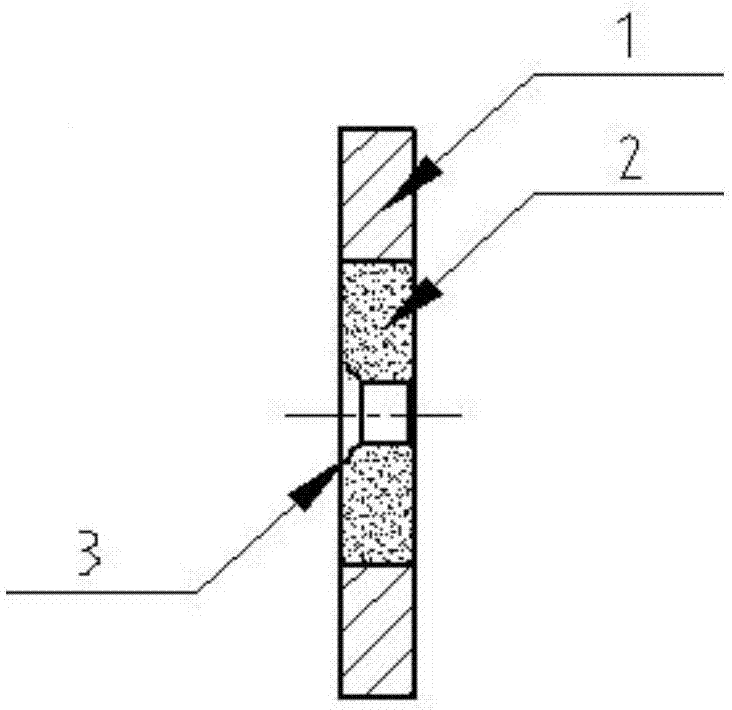

[0022] As shown in the figure: 1. Cylindrical ordinary metal fixing block, 2. Circular alloy rounding station, 3. Rounding blanking hole, 4. Graded rounding die fixing seat, 5. Grading rounding die installation and fixing holes, 6. Grading rounding die Holes for mounting bolts.

[0023] A rolling and grading and rounding device for sleeve-like parts, the operation steps are as follows:

[0024] After the pipe coiler is shut down, the original rounding device is removed, which mainly includes the fixed seat 4 of the graded rounding die and the rounding die installed in the installation and fixing hole 5 of the graded rounding die is replaced with a newly designed rounding die according to Schematic Diagram of Arrangement and Combination of Round Dies Three graded round dies are respectively installed in the fixing holes 5 of the graded round dies in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com