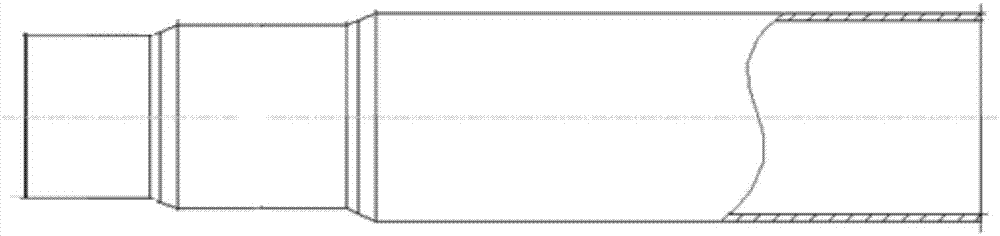

Tubular product multi-section one-time closing-in forming die and forming method

A one-time, forming mold technology, applied in the direction of metal extrusion molds, etc., can solve the problems such as the inability to ensure the uniformity of the benchmark, and achieve the effect of easy guarantee, easy mastery and low manufacturing cost of mold manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

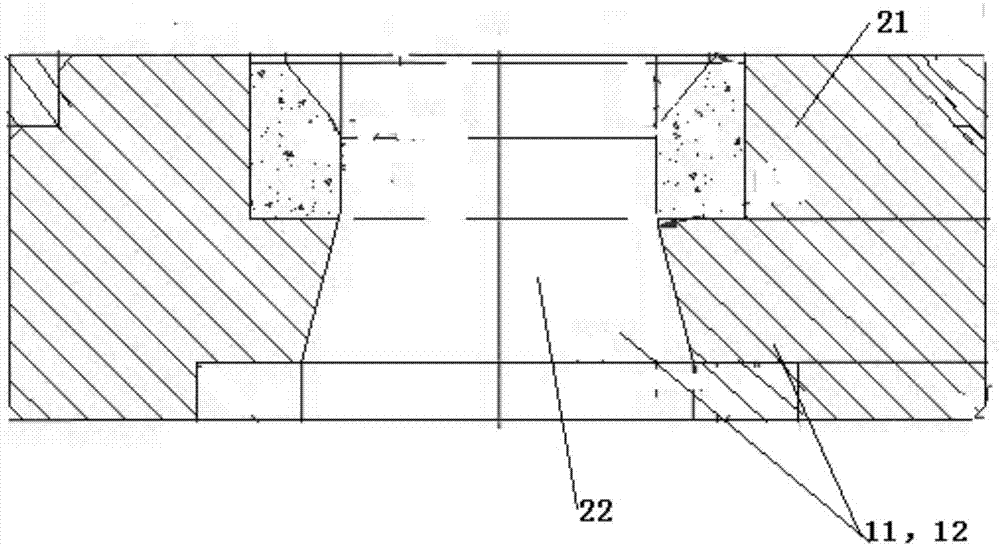

[0034] A multi-segment one-time closing forming mold for pipes, comprising a support plate, a lower mold seat, a backing plate, a concave mold plate, a discharge plate, a concave mold fixing plate, a concave mold two, a concave mold one, and a concave mold fixing plate arranged sequentially from bottom to top The sleeve and the upper mold base, the lower mold base, the backing plate, the concave plate and the discharge plate are tightly connected as one, the die fixing plate, the second die, the first die, the fixing sleeve of the die and the upper die base are tightly connected into one, There is a gap between the supporting plate and the lower mold base, and there is a gap between the unloading plate and the die fixing plate; the ejector rod passes through the lower die base, the backing plate and the concave formwork, and one end is fixedly connected with the supporting plate, and the other end is connected with the unloading plate. The material plate is fixedly connected; t...

Embodiment 2

[0041] A multi-segment one-time closing forming mold for pipes, comprising a support plate, a lower mold seat, a backing plate, a concave mold plate, a discharge plate, a concave mold fixing plate, a concave mold two, a concave mold one, and a concave mold fixing plate arranged sequentially from bottom to top The sleeve and the upper mold base, the lower mold base, the backing plate, the concave plate and the discharge plate are tightly connected as one, the die fixing plate, the second die, the first die, the fixing sleeve of the die and the upper die base are tightly connected into one, There is a gap between the supporting plate and the lower mold base, and there is a gap between the unloading plate and the die fixing plate; the ejector rod passes through the lower die base, the backing plate and the concave formwork, and one end is fixedly connected with the supporting plate, and the other end is connected with the unloading plate. The material plate is fixedly connected; the...

Embodiment 3

[0050] The multi-segment one-time closing forming method for pipes includes the following steps: (1) Assemble the mold and adjust the clearance: Assemble the mold according to the mold assembly drawing, and adjust the clearance between the die and the positioning mandrel through the adjusting screw on the fixing sleeve.

[0051] (2) Install the assembled mold on the vertical hydraulic press, and put it into the processed pipe fittings in the mold opening state. Under the pressure of the hydraulic press, the upper part of the mold goes down, and the pipe fittings are deformed through the combination of the first die and the second die and the positioning mandrel. , so as to achieve the purpose of processing and forming multiple steps at the same time.

[0052] (3) After descending to the position of the limit column, the hydraulic press returns, the die 1 and the die 2 are separated from the product, and at the same time as the hydraulic press returns, the lower oil cylinder is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com