Elastic wiring member

A wiring component, elastic technology, applied in the direction of printed circuit components, elastic polymer dielectrics, circuit bendable/stretchable components, etc., can solve the problems of not being able to elongate, etc., and achieve inhibition of peeling and connection The effect of excellent stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

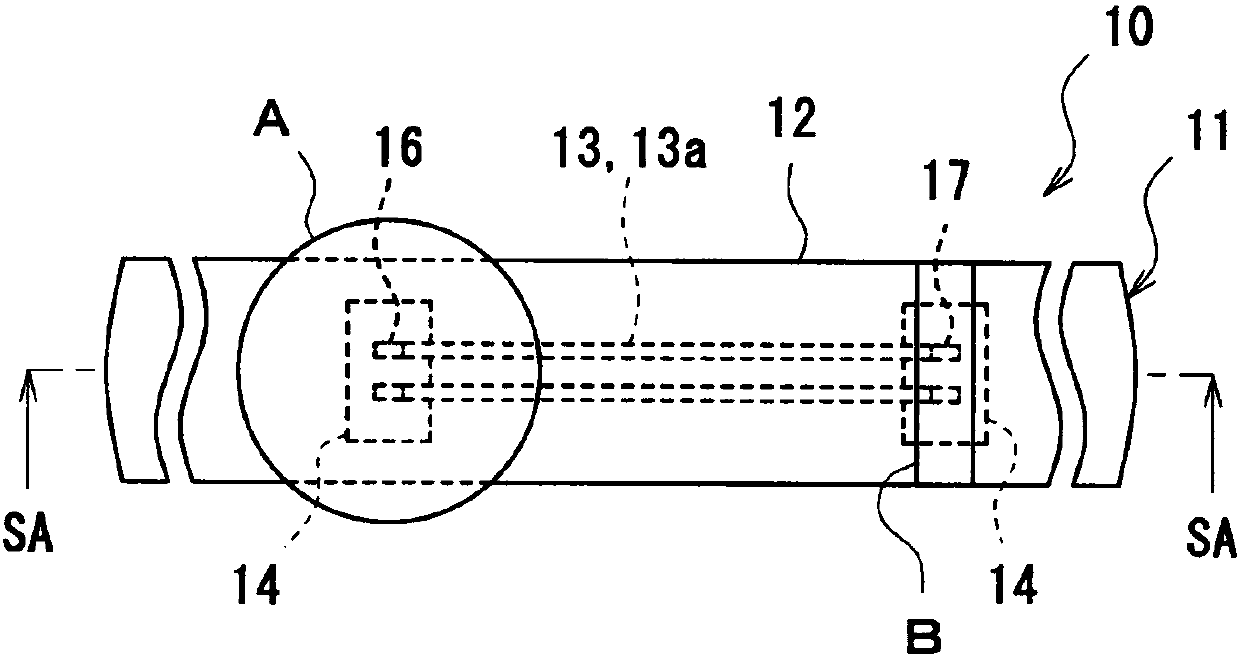

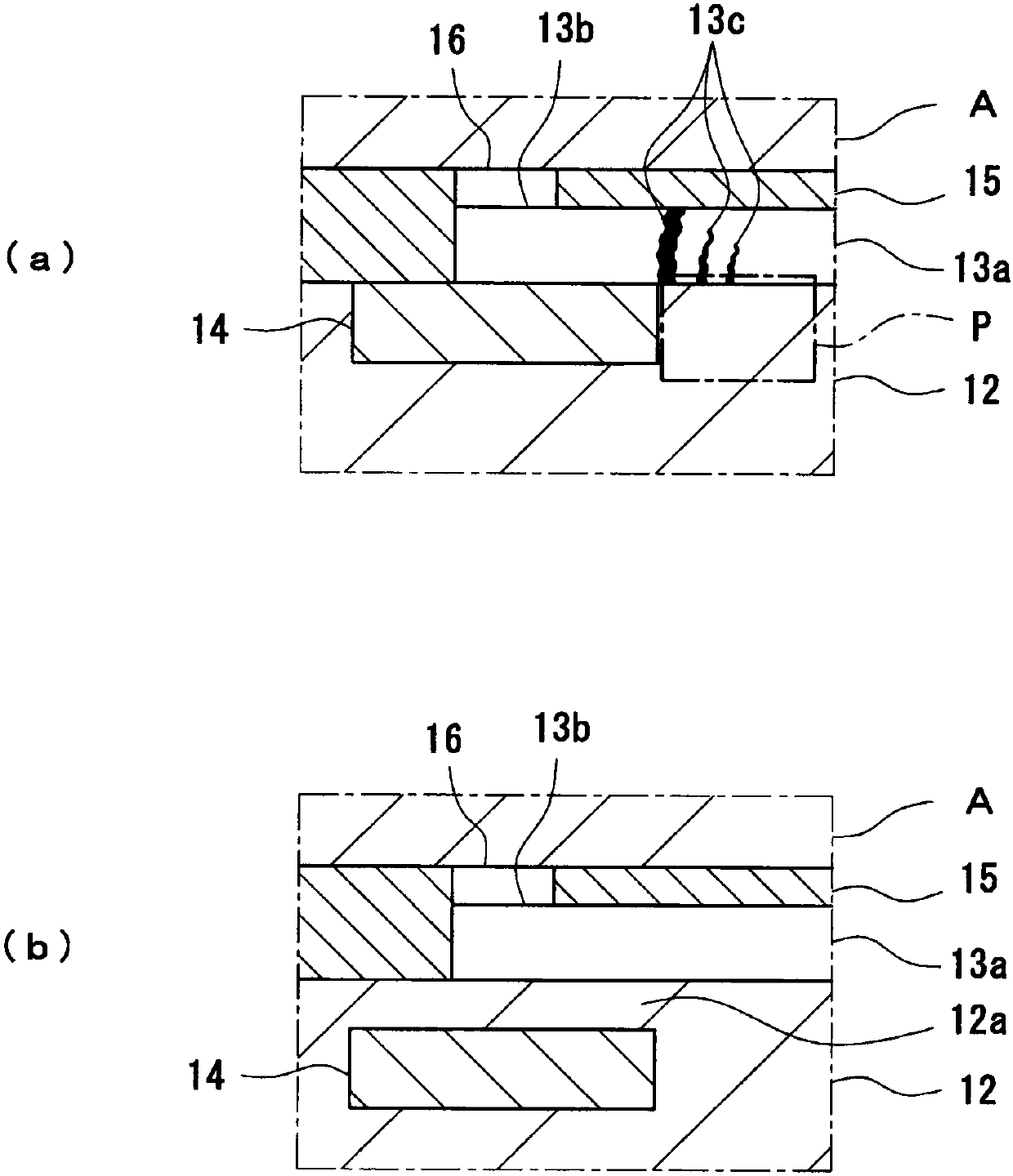

[0070] First embodiment: Figure 1 ~ Figure 4

[0071] exist Figure 1 ~ Figure 4 The elastic wiring member 11 of the first embodiment is shown in . figure 1 In order to schematically show a plan view of the electronic device 10, the electronic device 10 includes an electronic device main body A as a "connection object part" among the above-mentioned elastic wiring members 11, and an electronic component B as a "connection object part". figure 2 for its cross-sectional view. Here, the electronic device body A can be applied to a watch body such as a digital watch, and the electronic component B can be applied to an LED for lighting, for example, but the "connection object part" is not limited thereto.

[0072] Such as figure 1 or figure 2 As shown, in the electronic device 10 , the elastic wiring member 11 is connected to the main body A of the electronic device through the contact 16 , and is connected to the electronic component B through the contact 17 . The elastic...

no. 2 example

[0100] Second embodiment: Figure 6 ~ Figure 8

[0101] Now, the elastic wiring member 21 of the second embodiment will be described. Image 6 shown with Figure 4 A schematic plan view of the corresponding elastic wiring member 21, Figure 7 show Image 6 cross-sectional view. also, Figure 8 is a cross-sectional view when the substrate 12 is divided into two in the short-side direction. In these figures, the electronic components connected to the elastic wiring member 21 and the cover member 15 are omitted.

[0102] Compared with the elastic wiring member 11 of the first embodiment, the elastic wiring member 21 is different in the position and shape of the reinforcing member 24 . Such as Image 6 As shown, when viewed from the surface of the base sheet 12 (in a plan view), the reinforcing member 24 of the elastic wiring member 21 is provided at least three side positions surrounding the outer edge of the connecting portion 13b of the elastic wiring 13 (U glyphs), an...

no. 3 example

[0104] Third embodiment: Figure 9 , Figure 10

[0105] shows the elastic wiring member 31 of the third embodiment Figure 9 , is an enlarged plan view near contact 16, Figure 10 is its cross-sectional view. In addition, in Figure 9 or Figure 10 In both, the electronic components to be connected and the cover member 15 are omitted.

[0106] The elastic wiring member 31 of this embodiment also differs in the shape of the reinforcing member 34 from the elastic wiring members 11 and 21 of the other embodiments. Such as Figure 9 As shown, the reinforcing member 34 is also formed in a U-shape when viewed from above, so although it looks similar to the shape of the elastic wiring 24 at first glance, the elastic wiring 24 is formed by standing three planar reinforcing members in a U shape. The stretchable wiring 34 in this embodiment is different in that the planar reinforcing member is punched into a U-shape and then laminated on the surface of the base sheet 12 .

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com