Frame profiled element, wall element, and framework for a clean gas chamber

A technology of clean gas and wall components, applied in the direction of long-strip structural members for load-bearing, wing frame, window/door frame, etc., can solve the problems of large size, complicated installation and heavy weight of the inert gas shell, To achieve the effect of mechanical firmness, high bending rigidity and low weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

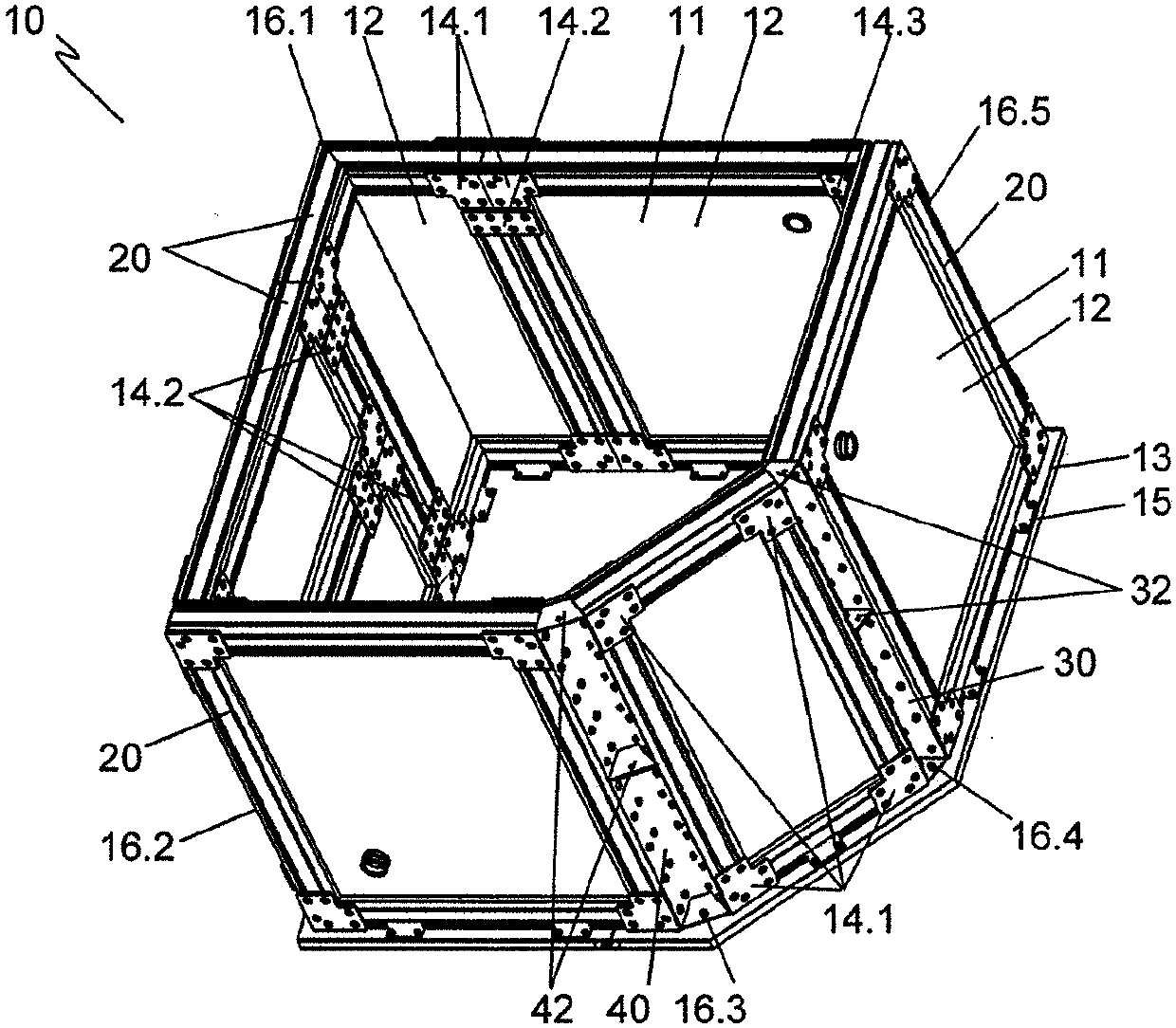

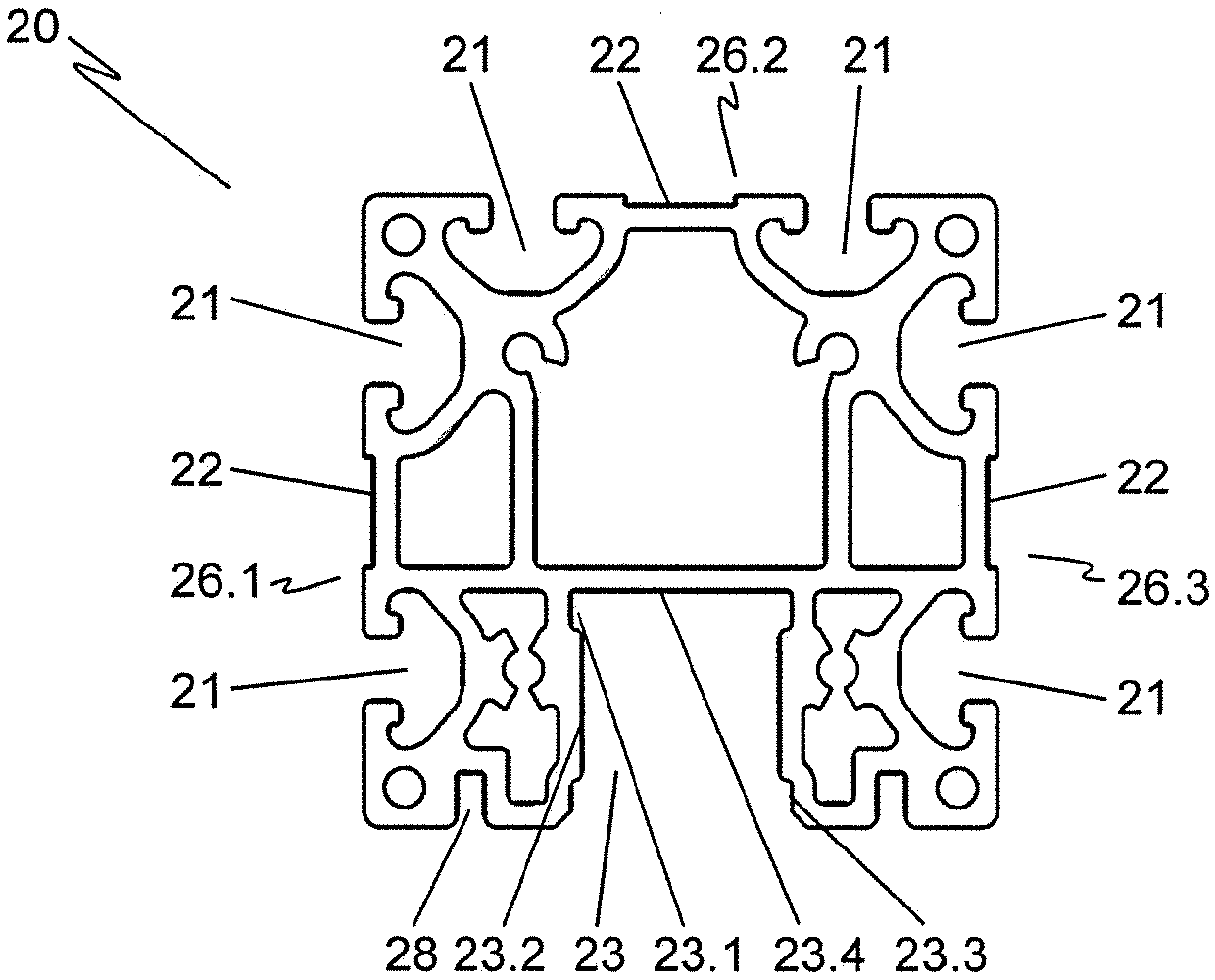

[0037] figure 1 A perspective view of a partially assembled clean gas chamber 10 with a frame made of frame profile A 20 is shown, in image 3 The frame profile A 20 is shown in more detail in .

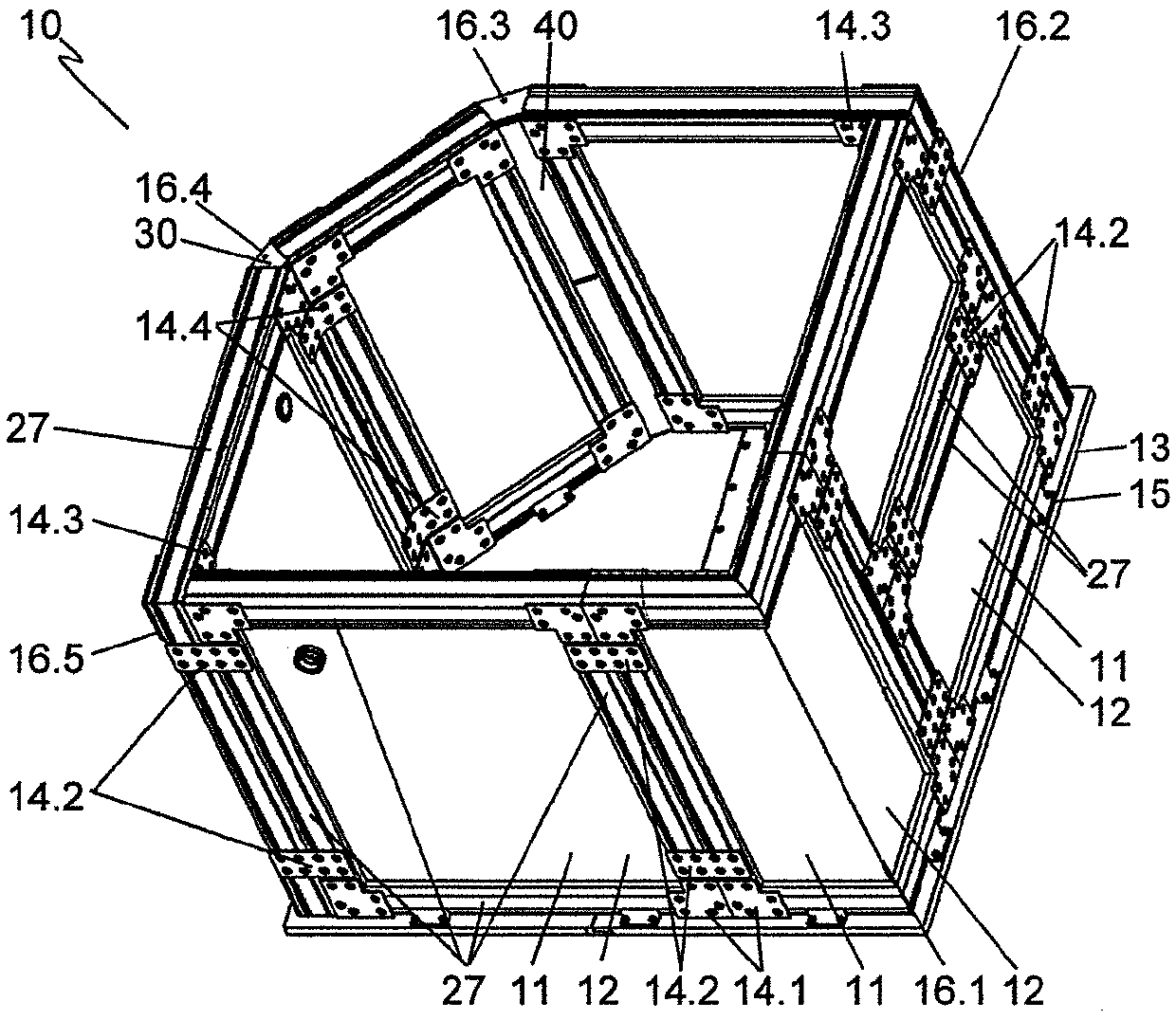

[0038] figure 2 shows the view from the opposite direction with the figure 1 Perspective view of a clean gas chamber assembled in the same part of the frame made of frame profile B 27, in Figure 6 The frame profile B 27 is shown in cross section in .

[0039] figure 1 and figure 2 The clean gas chamber 10 shown has a profile with five corners 16.1, 16.2, 16.3, 16.5 and 16.5. To this end, wall elements 11 in the form of side wall elements are placed along the outer edge of the base 13 and are connected to said base via holding brackets 15 . In the present case of an aluminum honeycomb core, the base 13 is formed by the structural core 12 . The wall element 11 is formed by a plate element surrounded by frame profiles 20 , 27 . In this exemplary embodiment the panel elements...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com