Blocking stator punching sheet, stator core and motor

A technology of stator punching and stator core, which is applied in the field of motors, can solve the problems of affecting electromagnetic noise and motor efficiency, large fluctuations in motor cogging torque, expensive winding machine equipment, etc., to reduce material costs, work magnetic The effect of small flux leakage and fast winding speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

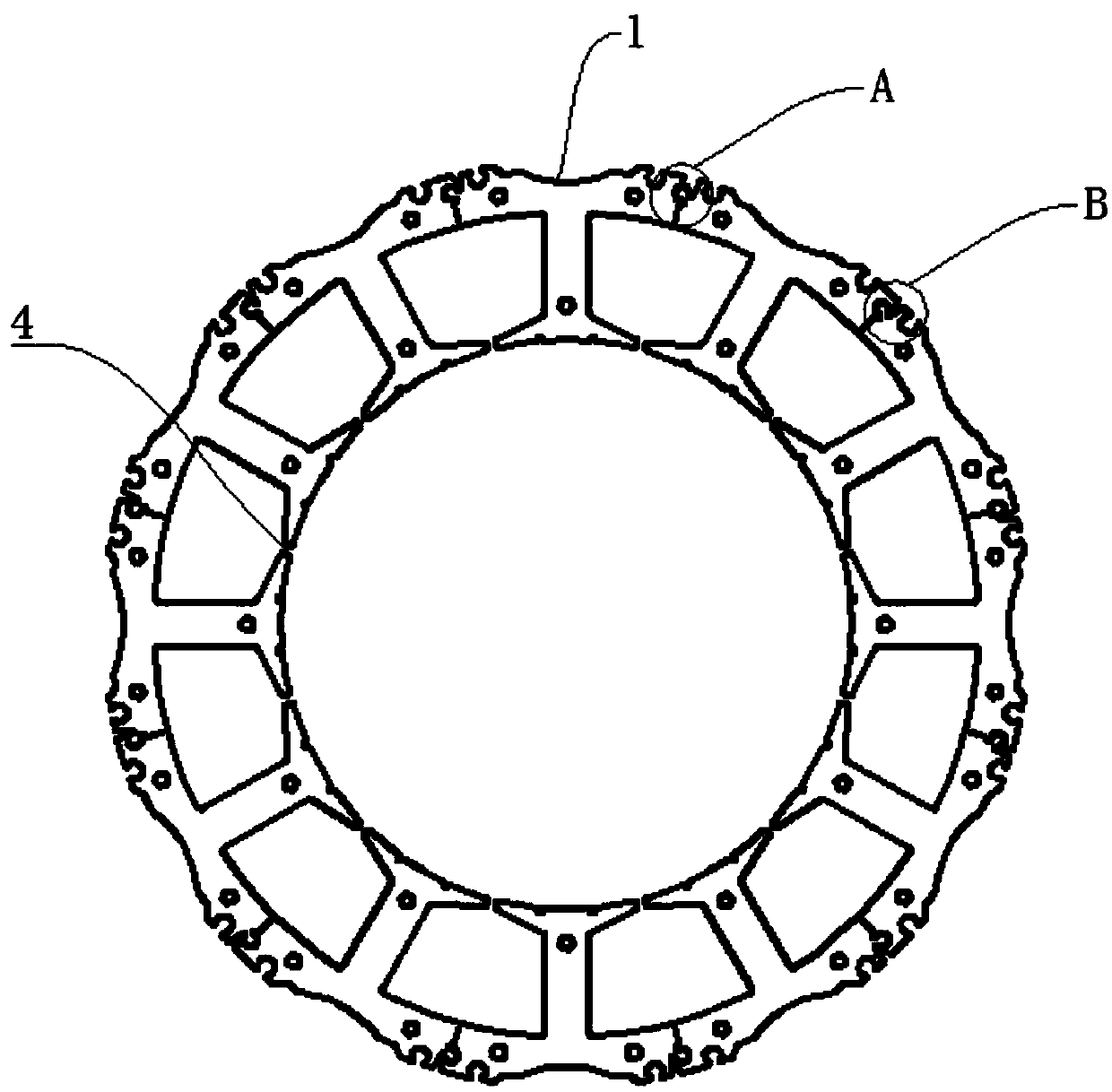

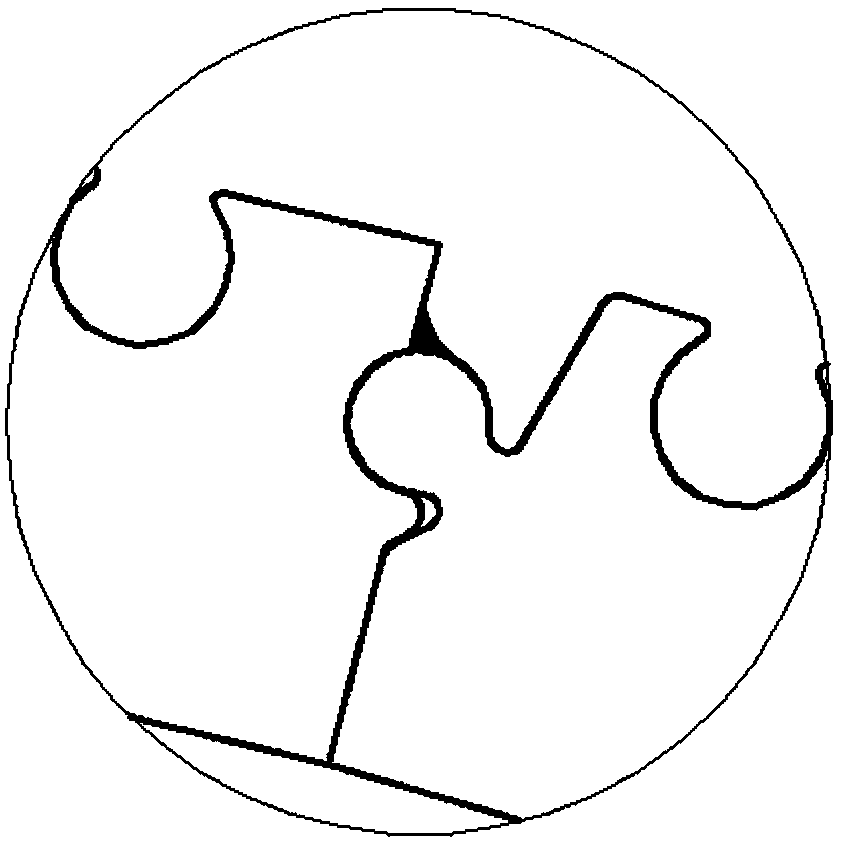

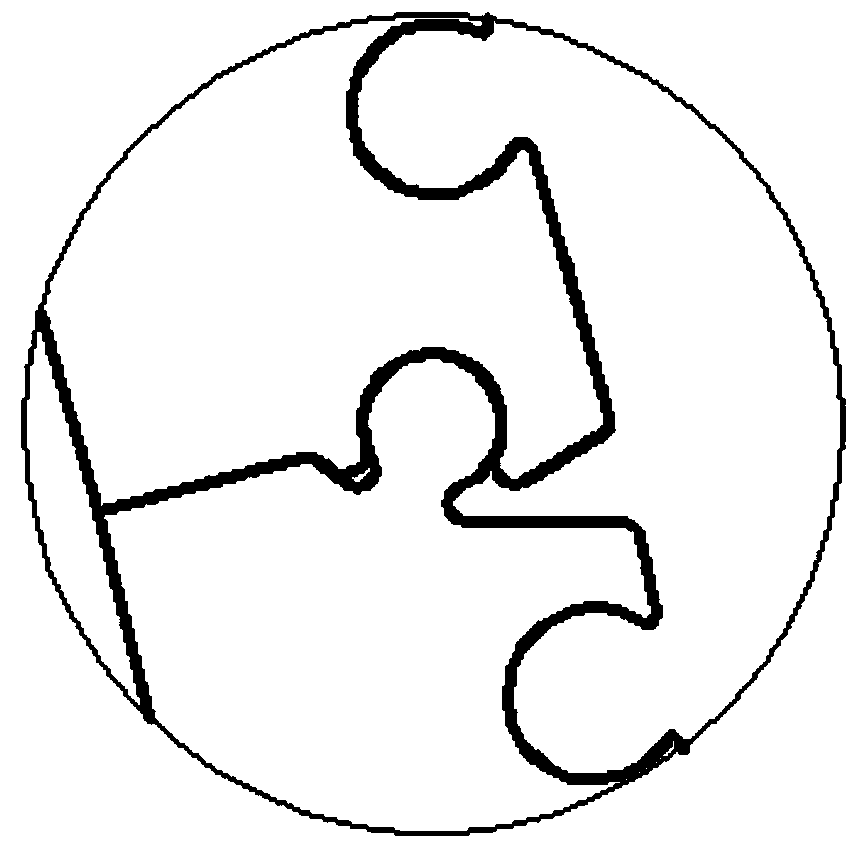

[0038] Such as figure 1 , 5 , 8, a segmented stator punching, including the stator punching body and stator teeth distributed radially on the circumference of the stator punching body, stator slots are formed between adjacent stator teeth, the segmented stator punching Slice 1 is formed by the end-to-end connection of independent tooth-shaped units 2. The bottom of the tooth-shaped unit 2 is provided with a virtual slot 5. The segmented stator punching sheet 1 has low requirements for high punching punches and molds. The iron cores can be double-rowed and arranged side by side. For the plug-in high punching die, the utilization rate of the silicon steel sheet material is high, and the waste material is less, which effectively reduces the material cost. The bottom of the tooth-shaped unit 2 is provided with a dummy groove 5, and the number of the dummy grooves 5 is 2. The structure is to reduce cogging torque, thereby reducing motor noise.

[0039] In the prior art, the slot ...

Embodiment 2

[0045] refer to figure 1 , 5 , 6, the structure of this embodiment is basically the same as that of Embodiment 1, and the similarities will not be repeated. The difference is that: the toothed unit 2 is provided with a rivet 3, and the rivet 3 is located on the horizontal plate 21 The two ends of the vertical plate 22 and the bottom end of the vertical plate 22, this structure is used for punching the self-fastening iron core of the mold, so as to cancel the manual riveting, and the riveting buckle 3 at the same position of the segmented stator punching piece 1 is at the same On a circle, the structure is center-shaped.

Embodiment 3

[0047] refer to figure 1, the structure of this embodiment is basically the same as that of Embodiment 1, and the similarities will not be repeated. The difference is that the width of the notch 4 of the segmented stator punching sheet is 0.8 mm, and the working magnetic flux leakage is small, which effectively reduces the Electromagnetic noise, improving motor efficiency.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com