Device for ultrasonically measuring thickness of oil film of cylinder piston ring

A technology of oil film thickness and cylinder piston is applied in the field of cylinder piston ring oil film testing device to achieve the effect of convenient focus, stable device measurement and guaranteed working temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

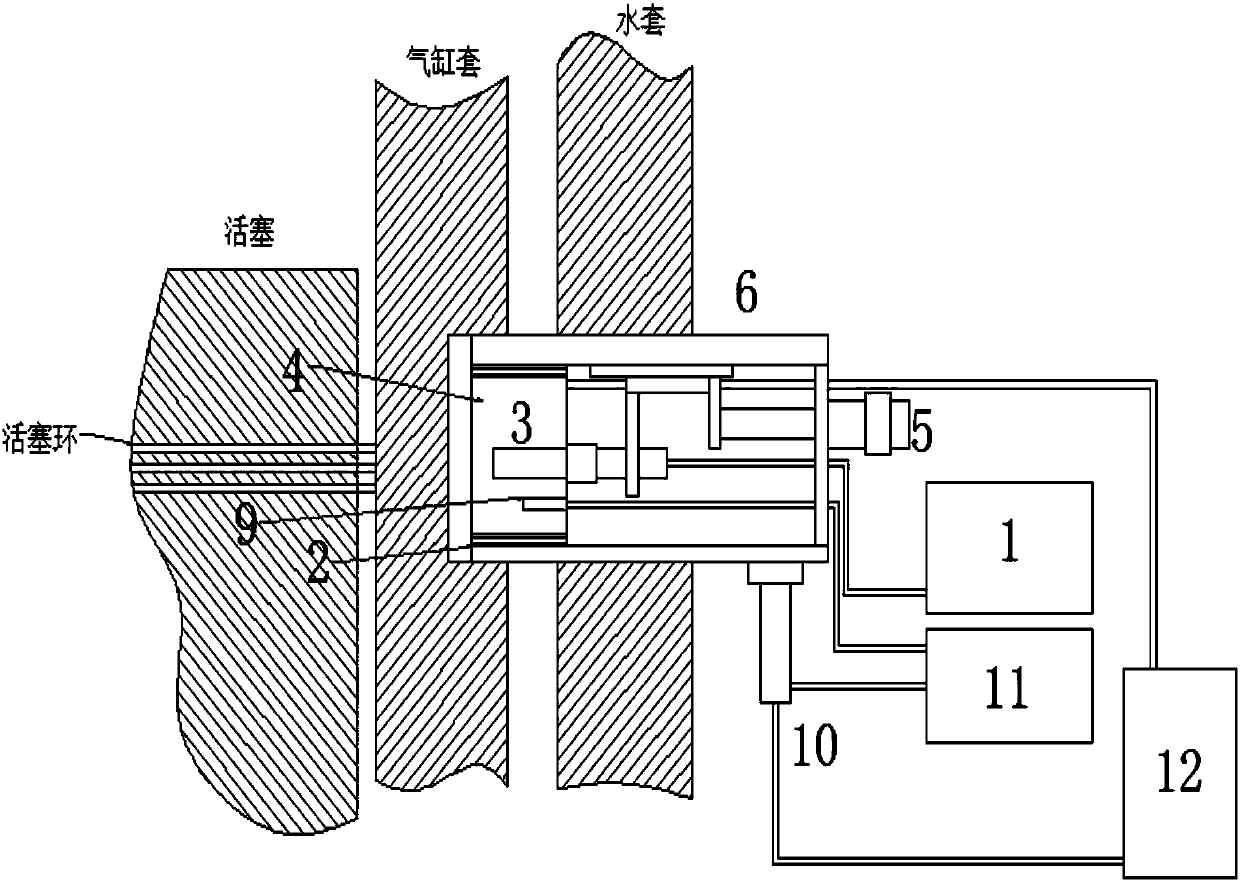

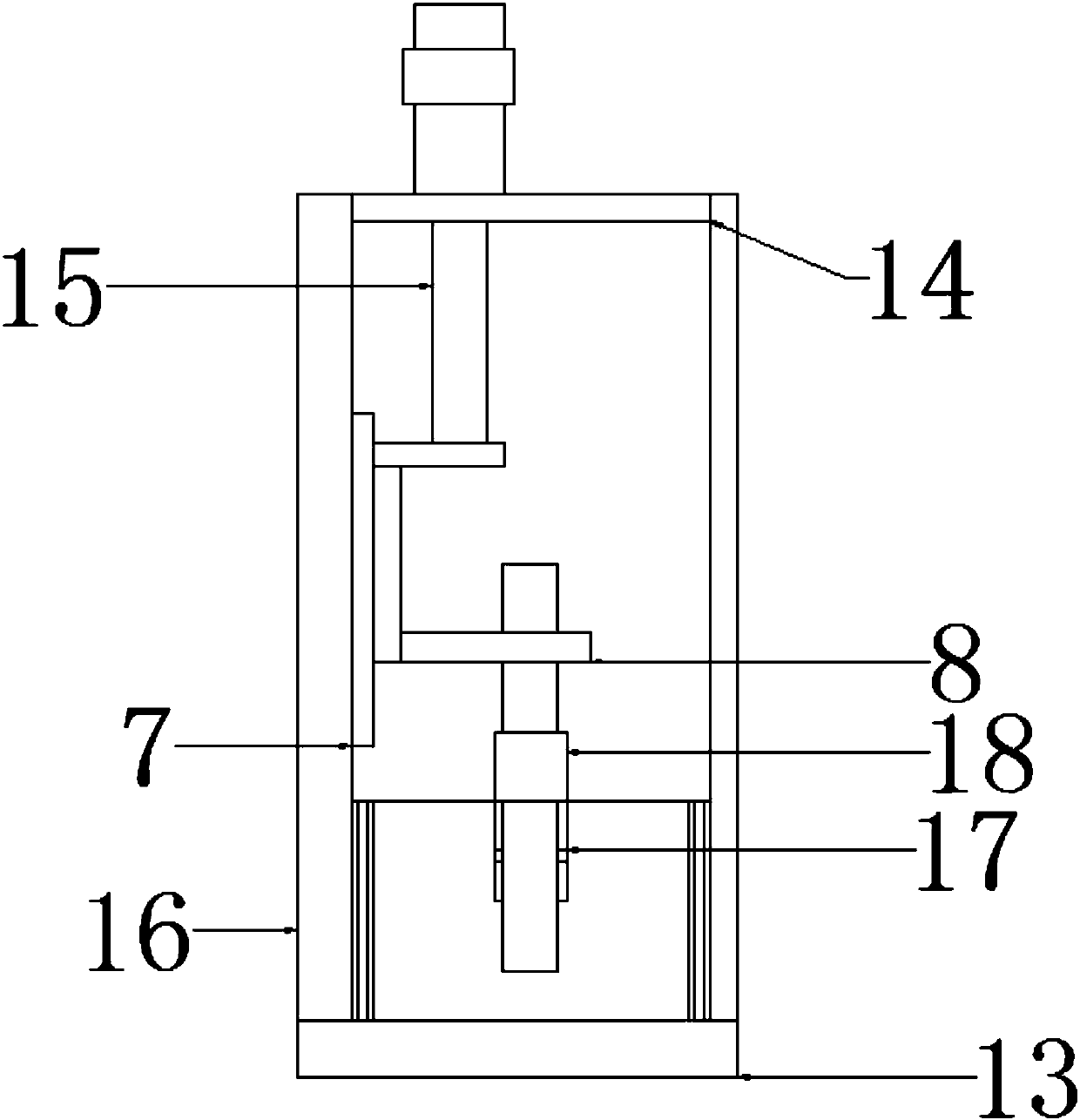

[0017] The present invention is described in more detail below in conjunction with accompanying drawing example:

[0018] combine Figure 1-2 , the present invention proposes an adjustable ultrasonic cylinder piston ring thin oil film thickness testing device, which can measure the thin oil film thickness of 1-20 μm. The device uses a spring model to calculate the thickness of the oil film through the ultrasonic reflection coefficient. The test device has higher measurement accuracy and a small minimum displacement, which can be as small as 1 μm, which improves the reliability and accuracy of the measurement result data. Since the working environment temperature of the transducer is about 50 degrees, and the transducer needs to be coupled with water, a circulating water cooling system is installed on the device, which can not only ensure the smooth operation of the transducer, but also reduce the impact of temperature changes on the measurement. influences.

[0019] The pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com