Double-rectangular copper pipe coiling water-cooling disk

A technology of water cooling plate and copper pipe, which is applied in lighting and heating equipment, heat exchanger fixing, heat exchange equipment, etc., can solve the problems of slowing down of cooling liquid flow rate, reduced heat dissipation effect, and uncompact structure of the cold water plate, and achieves the goal of welding The seam is firm and reliable, the length of the joint surface is extended, and the weld seam is dense

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

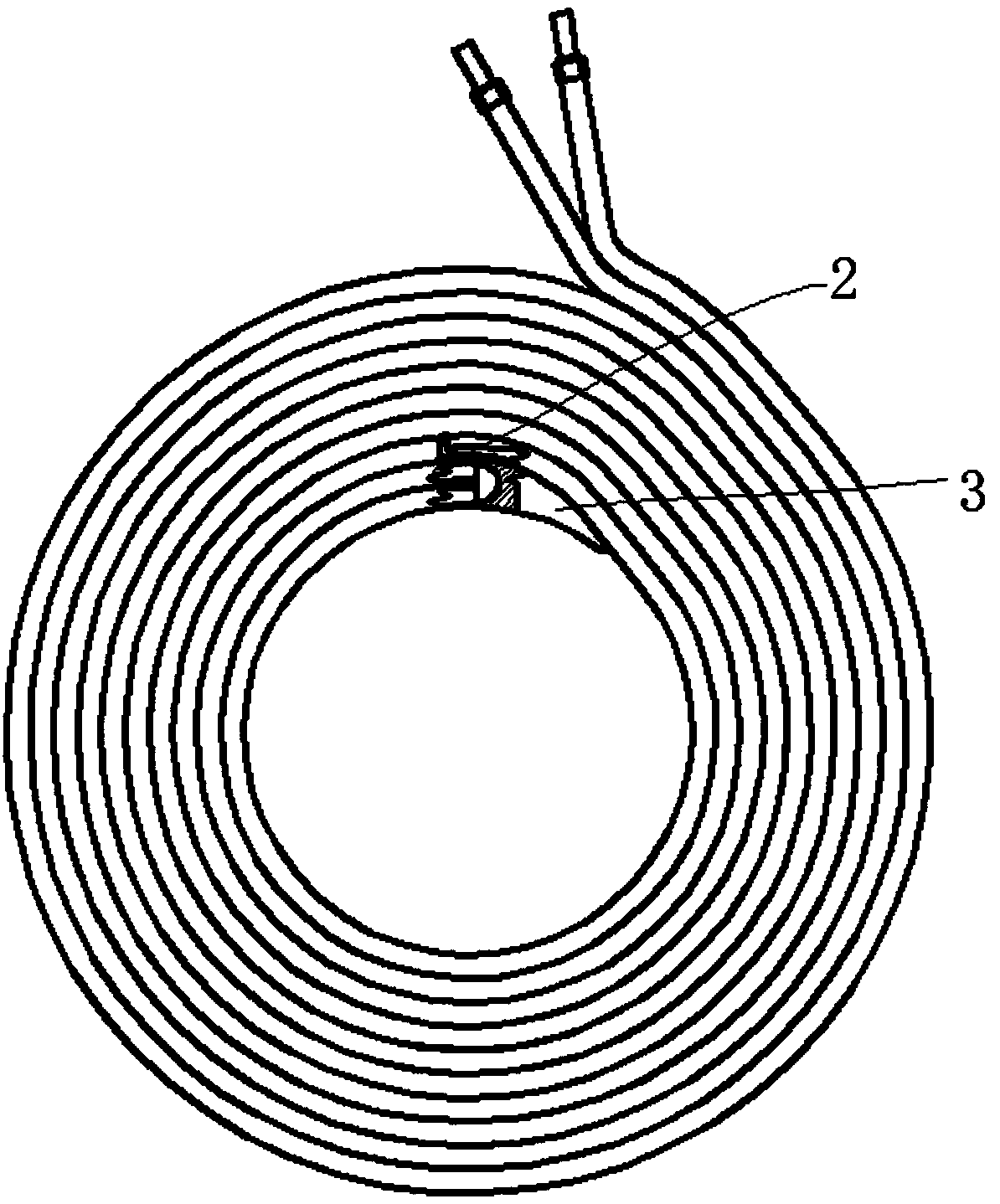

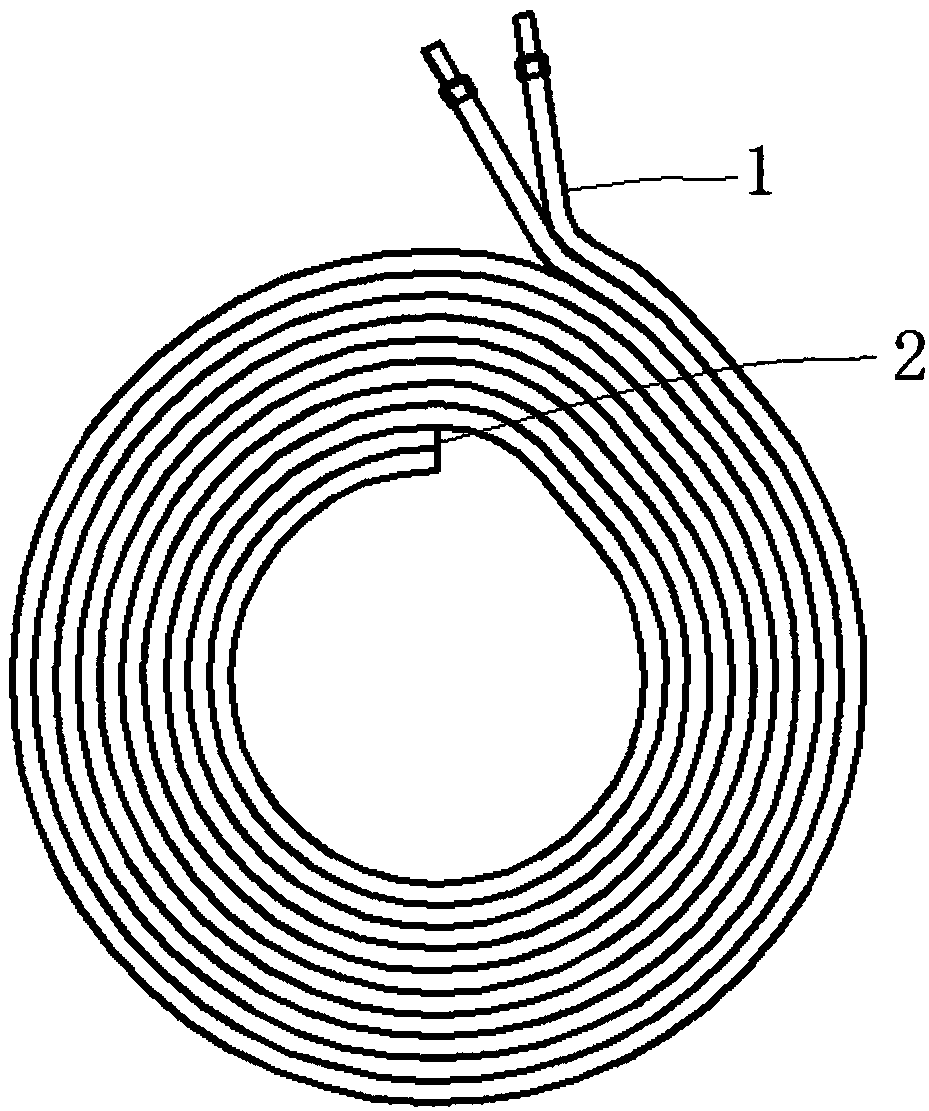

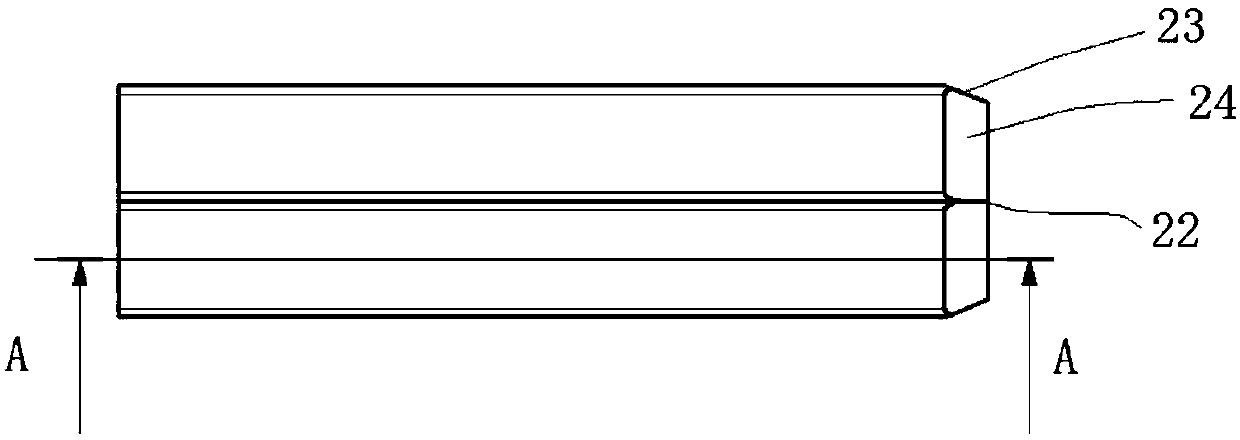

[0028] like Figures 3 to 7 As shown, a double rectangular copper tube winding water cooling plate includes two rectangular copper tubes, and the same end faces of each copper tube are attached to each other to form a circular water cooling plate 1 as a whole, and the copper tubes are located in the ring. One end is the connection port 2, the connection port 2 is connected through the joint body 3 to form a series loop, the connection port 2 includes two parallel copper pipe ports 21, and the two end faces of the copper pipe ports 21 that fit each other are vertically away from the connection port 2. The vertical side wall 22 extends in the direction of the copper pipe port 21, and the other end faces of the copper pipe port 21 extend away from the connection port 2 to form the inclined side wall 23. The vertical side wall 22 and the inclined side wall 23 are enclosed to form two shrinking openings 24. ; The joint body 3 includes a body 31 with an overall conical shape, the la...

Embodiment 2

[0034] As shown in the figure, the structure of this embodiment is basically the same as that of the first embodiment, and the similarities will not be repeated. The difference is that the connection port 2 and the joint body 3 can be connected in the form of a buckle and a ferrule. fixed, and a sealing ring is provided between the connection port 2 and the joint body 3, so that the assembly process between the connection port 2 and the joint body 3 can be simplified, thereby reducing the production cost, and the provided sealing ring can effectively The cooling liquid in the rectangular copper tube is prevented from flowing out, so that the safety performance of the cold water pan 1 is improved, so that the assembly steps are simplified and the production cost is reduced under the premise of realizing all the beneficial effects of the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com