Heat pipe sealing structure

A sealing structure and heat pipe technology, which is applied in indirect heat exchangers, lighting and heating equipment, etc., can solve the problems of leakage of the sealing structure at the partition plate of the heat pipe heat exchanger, and achieve low processing cost, simple and convenient disassembly and replacement, and simple installation convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

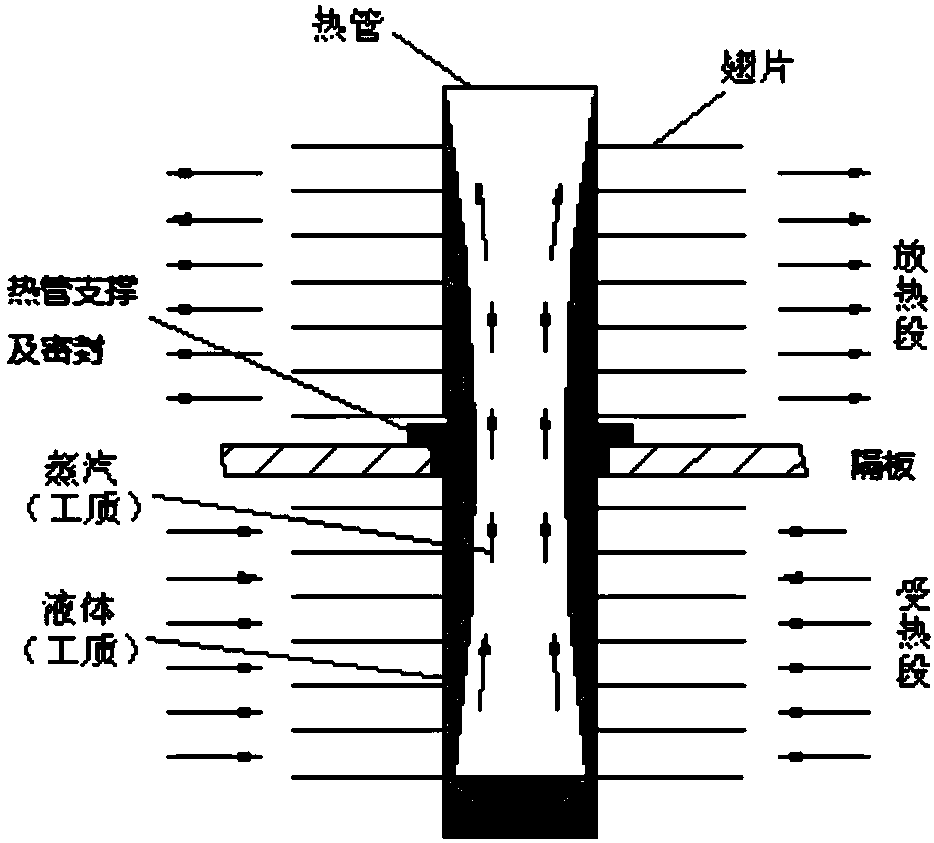

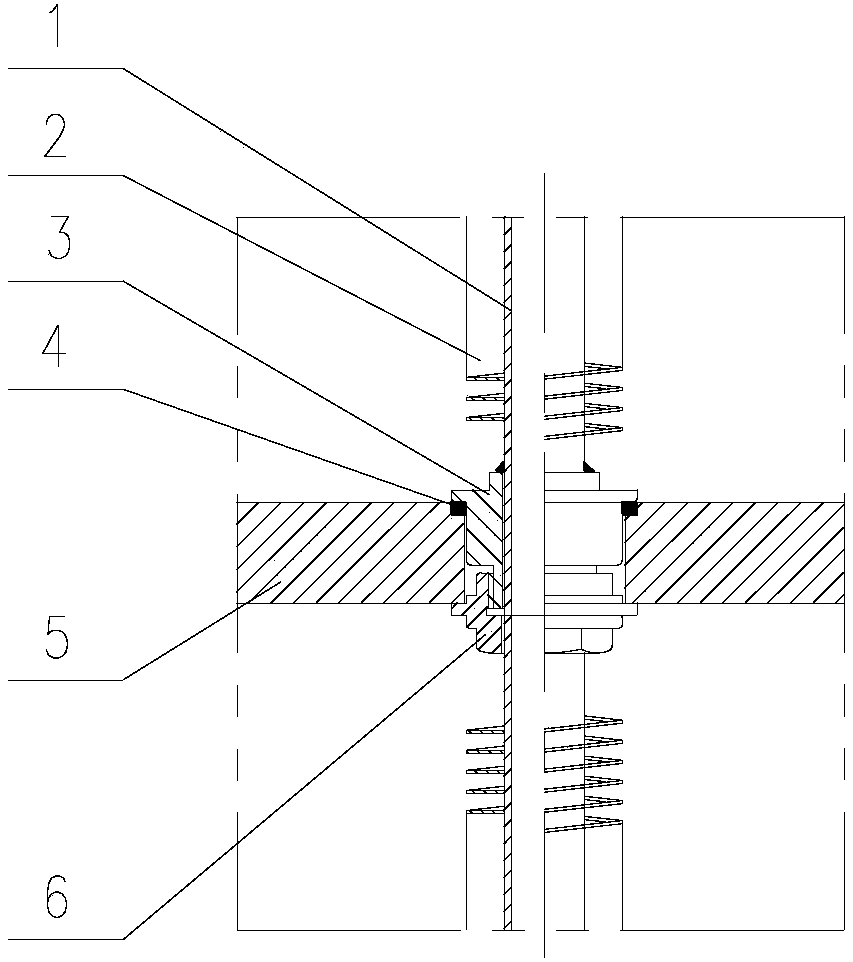

[0024] like figure 2 As shown, the heat pipe sealing structure of the present invention includes a partition 5 , a sealing block 3 , a sealing ring 4 , and a compression nut 6 .

[0025] The heat pipe 1 can be a light pipe, a finned pipe and other structures;

[0026] The sealing surface of the gasket on the partition is set above the hole of the partition and sinks into the partition, which is convenient for the sealing ring 4 to limit and protect the sealing surface;

[0027] The sealing block 3 is welded with the heat pipe 1, and is installed from the top to the partition hole along with the heat pipe 1. The upper part is provided with a sealing surface to compress the sealing ring 4, and the lower part is provided with an external thread to cooperate with the internal thread of the compression nut 6;

[0028] The compression nut 6 is installed below the partition hole, and the purpose of compressing the sealing ring is achieved by rotating the compression nut 6 .

[002...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com