Multifunctional dehumidifying and drying machine system

A kind of dryer and multi-functional technology, which is used in local stirring dryers, dryers for static materials, dryers, etc., can solve the problems of long drying time, low dehumidification energy efficiency, unstable system, etc., to ensure reliable operation. performance and stability, system dehumidification performance ratio improvement, and the effect of improving SMER value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

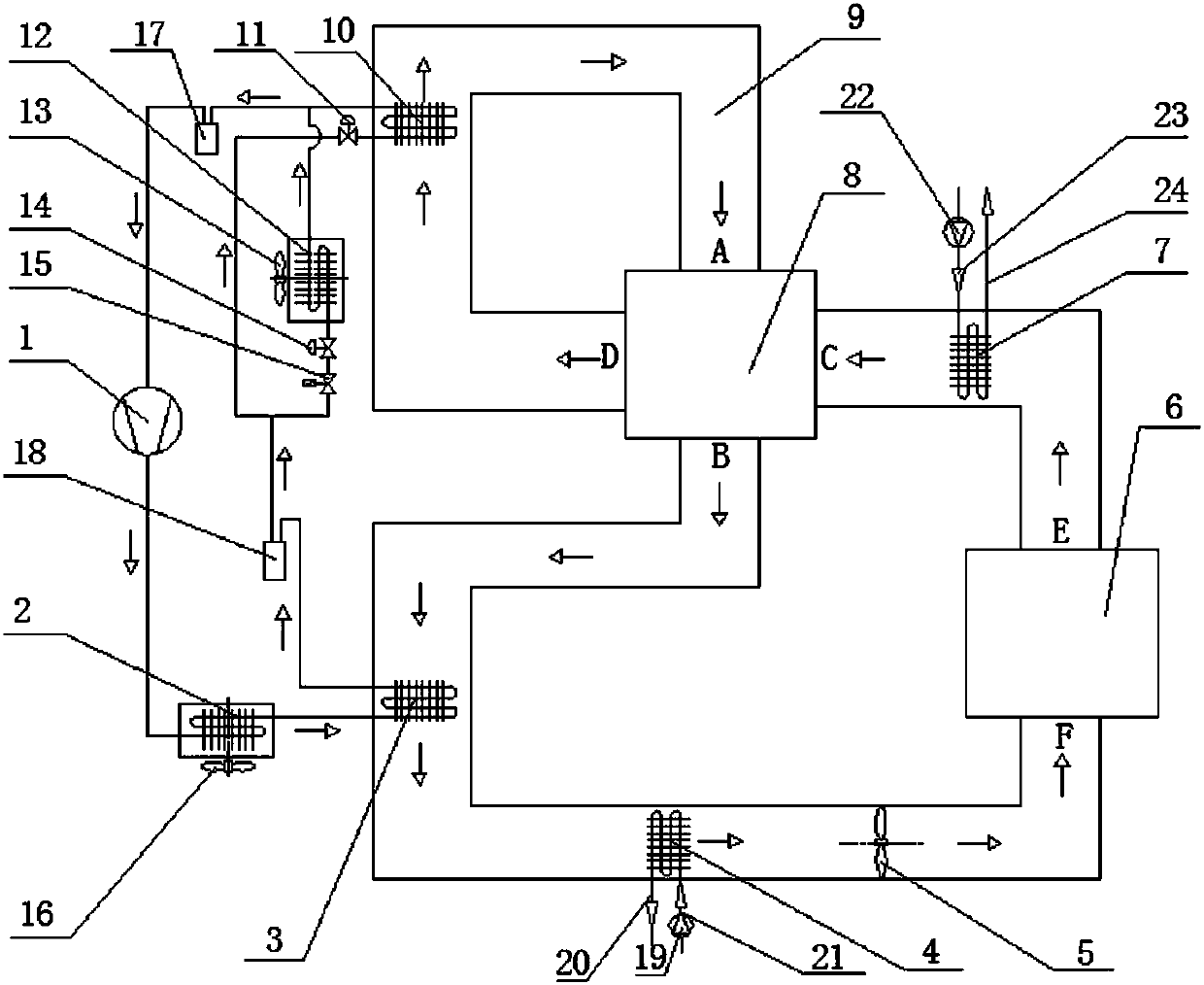

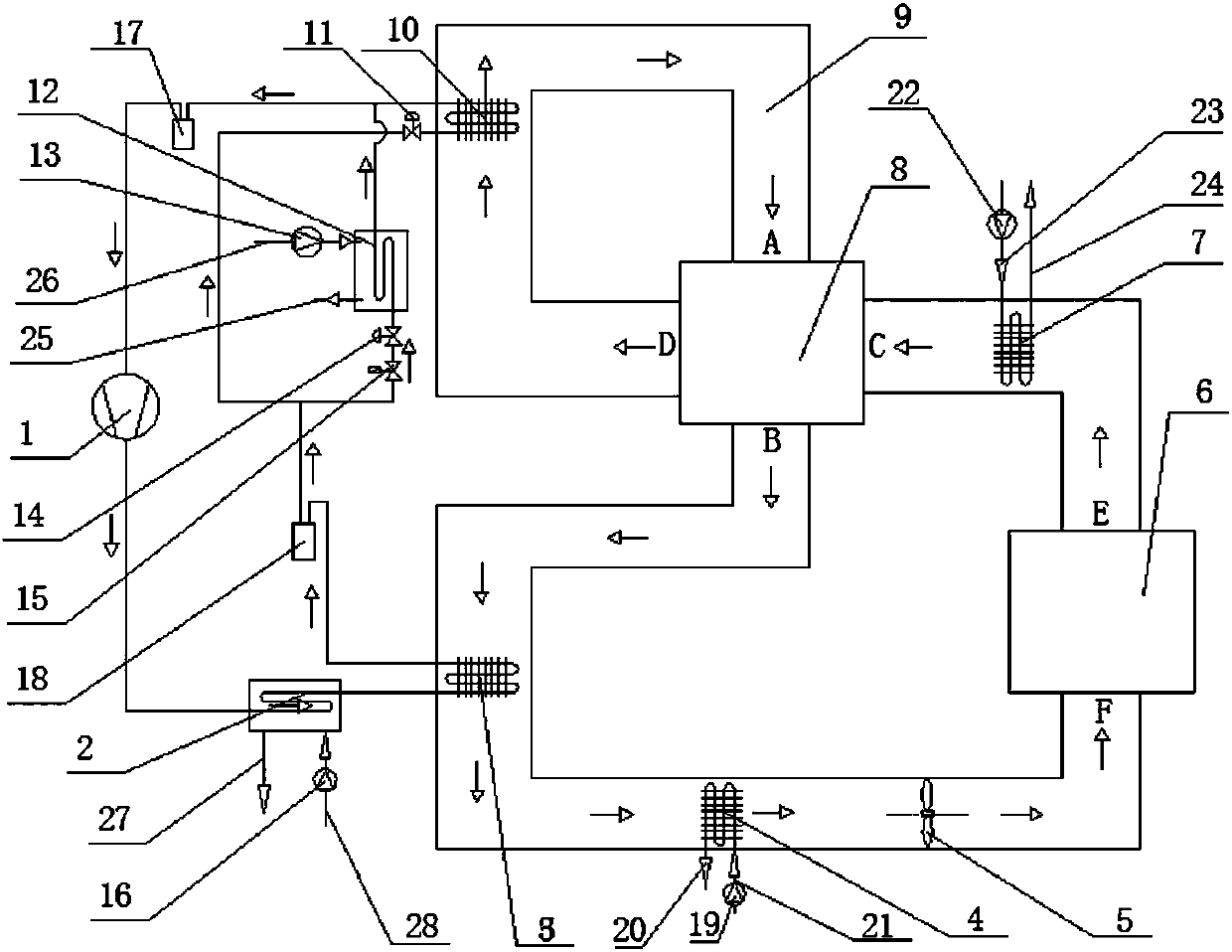

[0048] Such as Figure 1-Figure 2 As shown, it includes drying medium flow and refrigerant flow.

[0049] 1. The process of circulating dehumidification and drying medium is as follows: Figure 1-Figure 2 as shown,

[0050] Drying box 6 (air outlet E) → temperature-adjusting cooler 7 → heat recovery device 8 (C into D out) → evaporator 10 → heat recovery device 8 (A into B out) → condenser 3 → auxiliary heater 4 → Circulation fan 5→drying box 6 (air inlet F).

[0051] The outlet E of the drying box 6 is connected to the temperature adjustment cooler 7 through the air duct 9, the temperature adjustment cooler 7 is connected to the inlet C of the heat recovery device 8 through the air duct 9, and the outlet D of the heat recovery device 8 is through the air duct 9 It is connected to the evaporator 10, the evaporator 10 is connected to the inlet A of the heat recovery device 8 through the air duct 9, the outlet B of the heat recovery device 8 is connected to the condenser 3 th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com