Single-H-structure gearbox air path control mechanism

A gas circuit control and gearbox technology, applied in the field of gearboxes, can solve problems such as the inability to install gas circuit control valves, and achieve the effects of simple structure, error prevention, and improved stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described in detail below in conjunction with the accompanying drawings, which are explanations rather than limitations of the present invention.

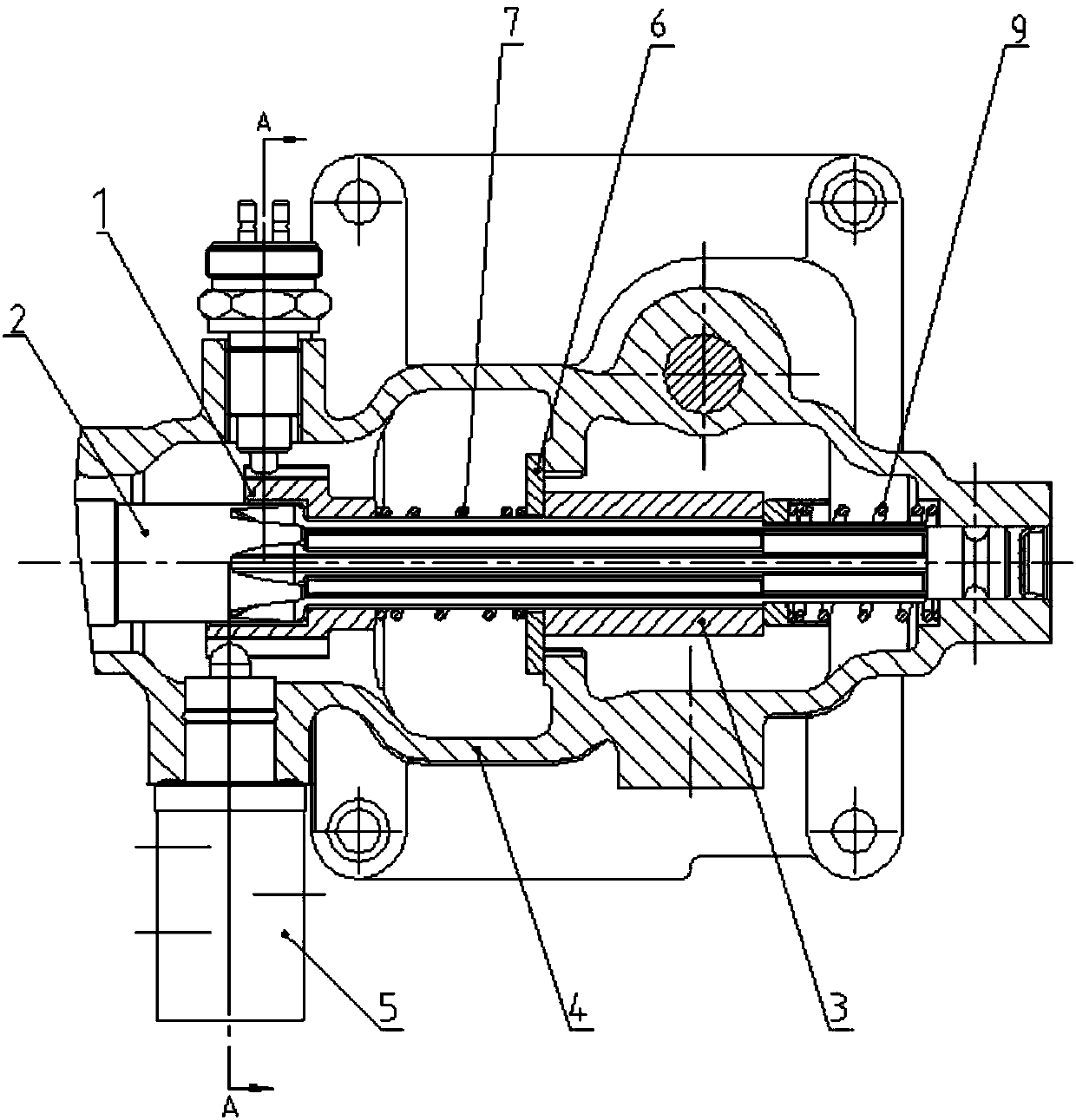

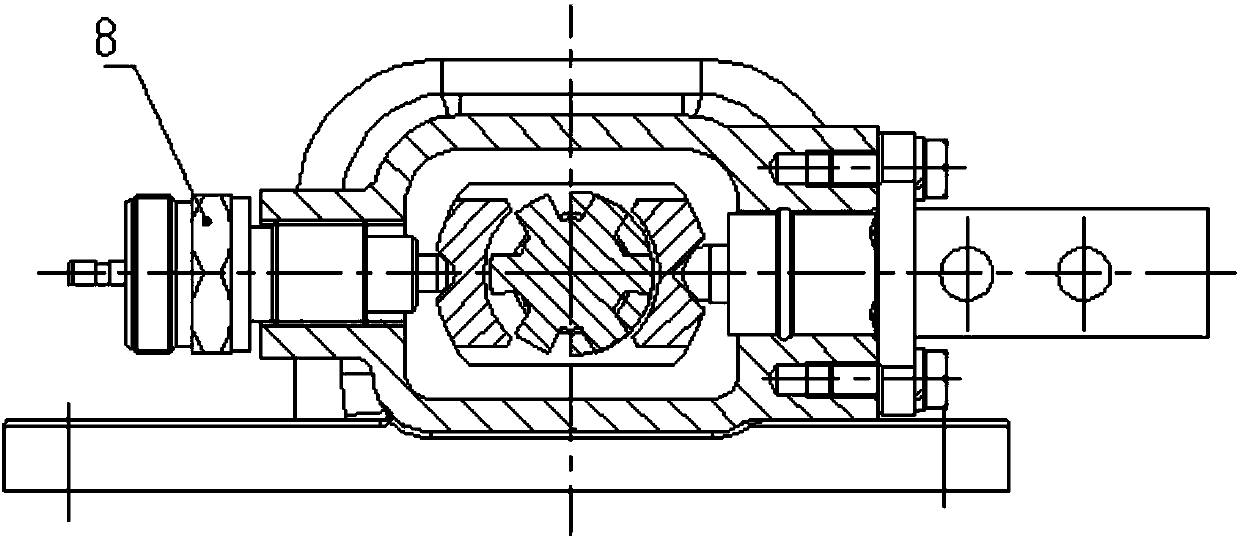

[0034] The present invention provides an air circuit control mechanism of a single H structure gearbox, including a housing 4, a control block 1, a horizontal shift lever 2, a shift dial 3, an air circuit control valve 5, a spring spacer 6, a A spring 7, a second spring 9 and a neutral indicator switch 8.

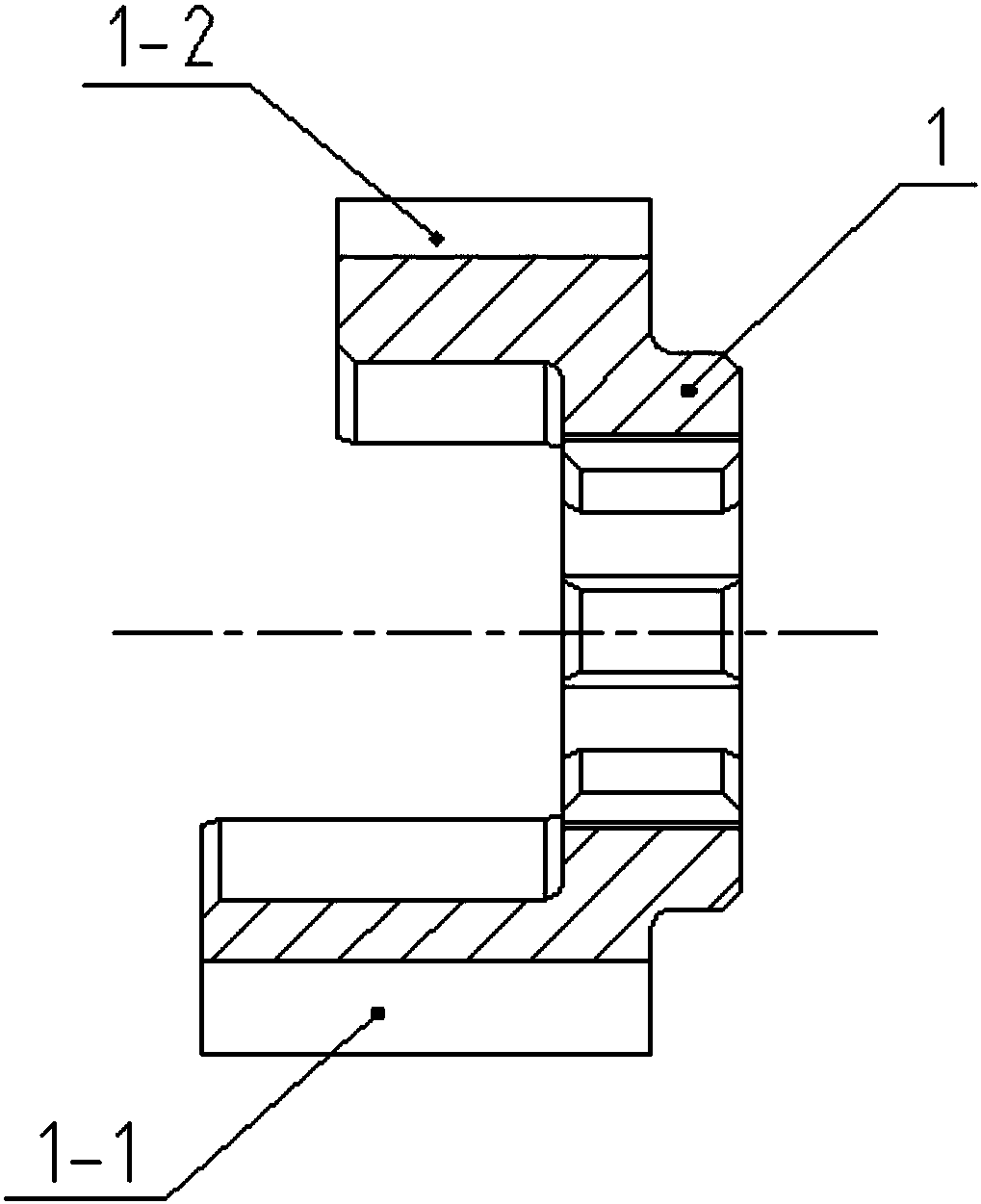

[0035] Among them, there are two symmetrical installation holes on the housing 4, and the gas circuit control valve 5 and the neutral indicator switch 8 are respectively installed in the two installation holes; the horizontal shift lever 2 is a stepped shaft, which is horizontally installed on the housing In the middle and can be rotated, the control block 1, the first spring 7, the spring spacer 6, the shift dial 3 and the second spring 9 are successively installed on the horizontal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com