Alcohol-based fuel system and cold-start device thereof

An alcohol-based fuel, cold start technology, applied in the direction of charging system, liquid fuel feeder, engine components, etc., can solve the problem that methanol is not easy to start

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

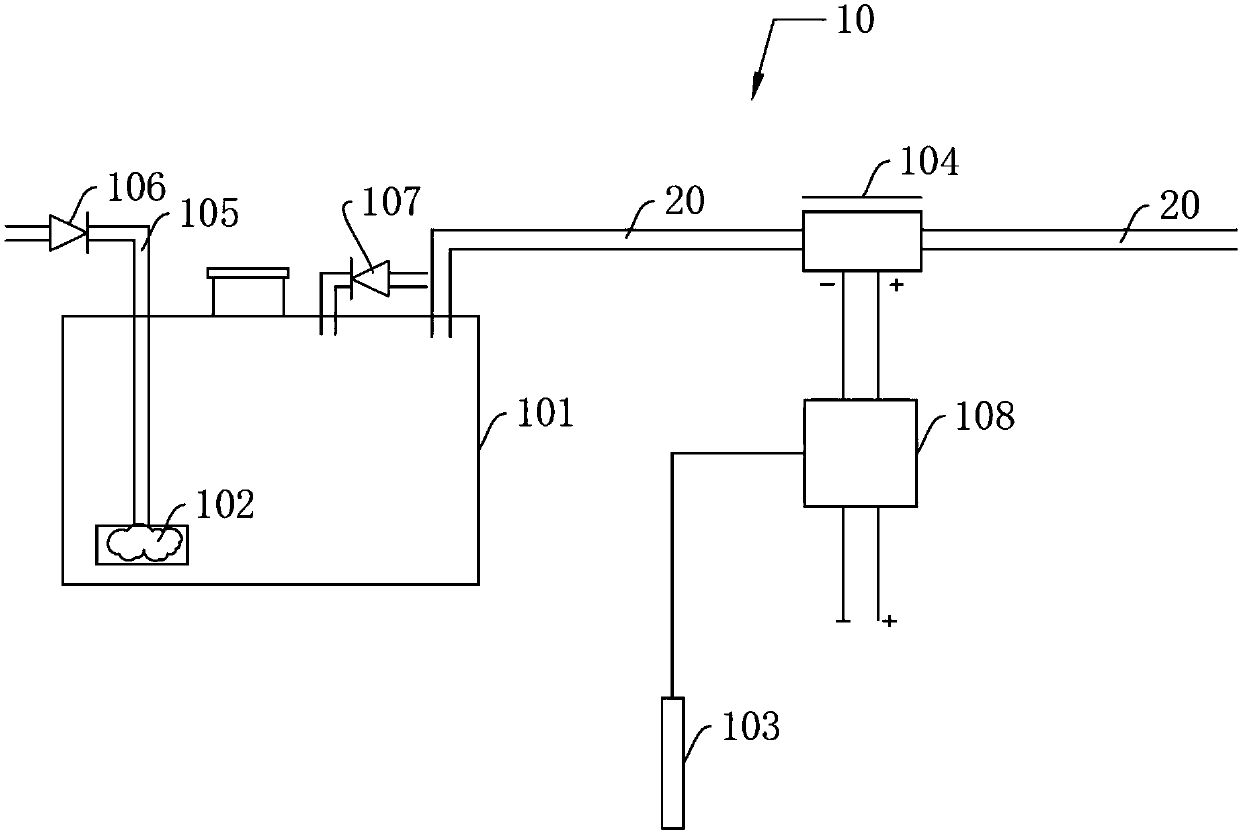

[0030] figure 1 A schematic structural diagram of the cold starting device 10 is shown.

[0031]The cold start device 10 is applied to the alcohol-based fuel system 1 as an auxiliary device when an engine using alcohol-based fuel is started at a low temperature. Adding the cold start device 10 provides the engine with gasified oil, thereby increasing the content of oil and gas in the engine, making the ignition of the engine easier and reducing the cold start time of the engine. The cold start device 10 includes a cold start oil tank 101 , an oil and gas generator 102 , a temperature sensor 103 and a solenoid valve 104 . The cold start tank 101 supplies fuel to the engine through the fuel rail 20 .

[0032] The cold start oil tank 101 is a container for the cold start device 10 to hold oil, and the oil in the cold start oil tank 101 is the same as the oil in the main oil tank. In this embodiment, the cold start device 10 is applied to a methanol-gasoline mixed alcohol-based...

Embodiment 2

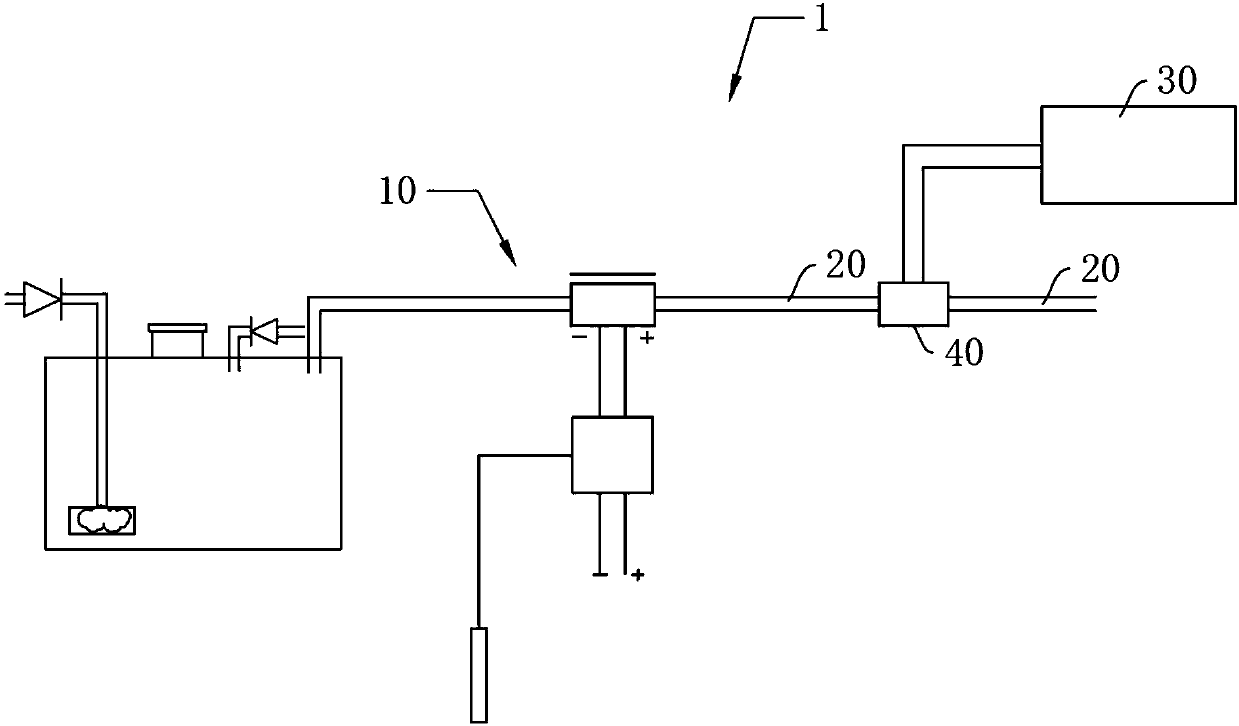

[0046] figure 2 A schematic structural view of the alcohol-based fuel system 1 is shown.

[0047] This embodiment provides an alcohol-based fuel system 1, which includes a fuel rail 20, a fuel tank 30 and the cold start device 10 of Embodiment 1. The fuel tank 30 is arranged on the fuel rail 20 , and the gas in the cold start fuel tank 101 flows to the fuel rail 20 through the solenoid valve 104 to mix with the oil in the fuel tank 30 .

[0048] Alcohol-based fuel is contained in the fuel oil tank 30, and alcohol-based fuel is exactly the fuel that uses alcohols (such as methanol, ethanol, butanol, etc.) to configure gasoline or diesel oil. The alcohol-based fuel in this embodiment is methanol gasoline, and the alcohol-based fuel system 1 supplies methanol gasoline to the engine. When the engine is cold started, it is difficult to start the methanol gasoline, so a cold start device 10 is added to the alcohol-based fuel system 1 to assist the engine start. Methanol gasoline...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com