Noise-reducing closed house for robot stamping line

A stamping line and robot technology, applied in the direction of sealing devices, fastening devices for wings, fastening devices for buildings, etc., can solve the problems of poor use of noise-reducing closed rooms and achieve good sound insulation and noise reduction effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] In order to deepen the understanding of the present invention, the present invention will be further described below in conjunction with the examples, which are only used to explain the present invention, and do not constitute a limitation to the protection scope of the present invention.

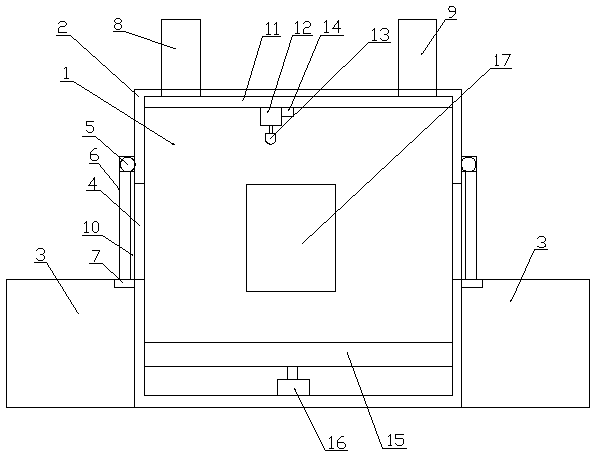

[0013] Such as figure 1 As shown, this embodiment provides a noise-reducing closed room for a robot press line, including a room body 1, and a sound-absorbing and sound-insulating cotton layer 2 is arranged on the inside of the room body 1; a transportation platform is arranged at the lower parts of the left and right sides of the room body 1 3. There are openings 4 on the left and right sides of the room body 1 above the transportation platform 3, and a rotating shaft 5 is arranged on the outer side of the opening 4. An iron sound-proof door 6 is connected below the rotating shaft 5. The inner top of the transportation platform 3 is located below the sound-proof door 6. A magnetic b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com