Vertical annealing furnace for bonding wire

A technology of vertical annealing furnace and bonding wire, applied in the direction of furnace, heat treatment furnace, furnace type, etc., can solve the problems of slow cooling speed, high cost, long cooling time, etc., achieve good cooling effect, not easy to oxidize, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

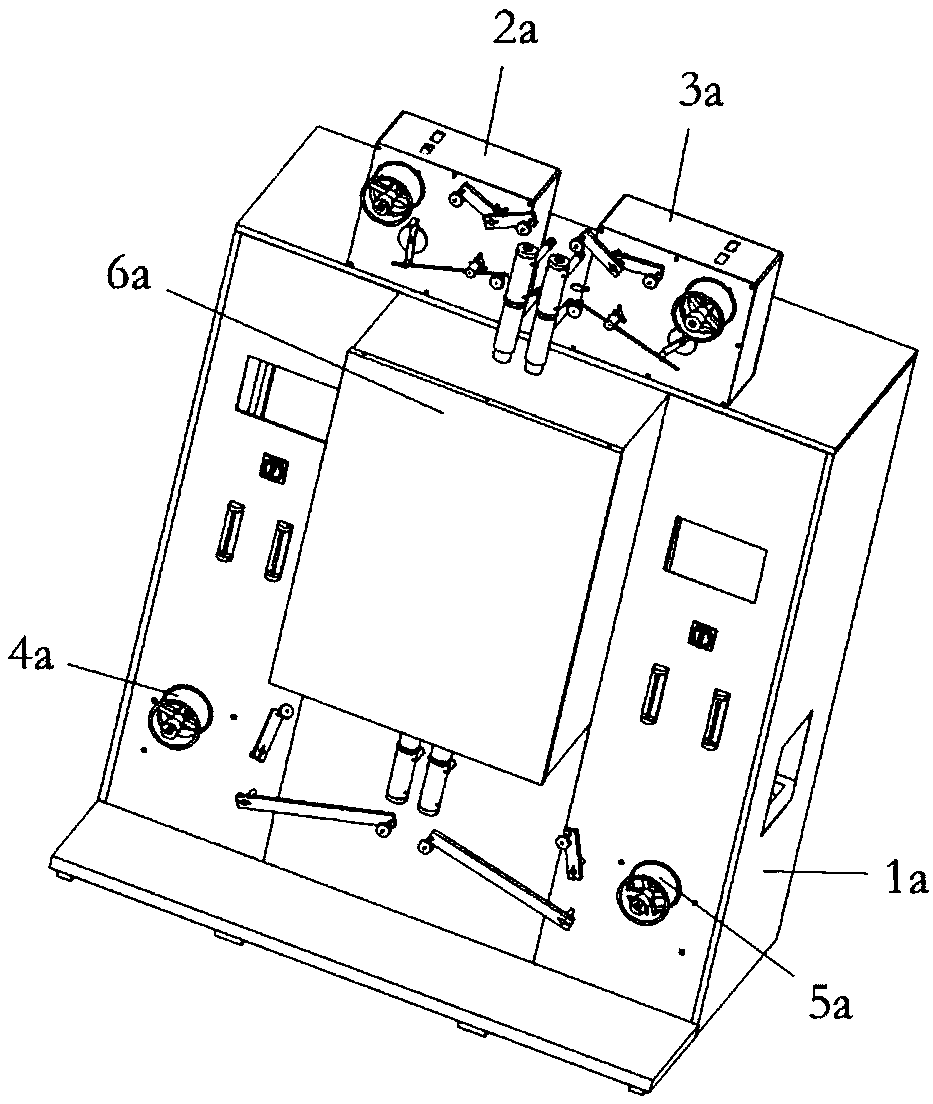

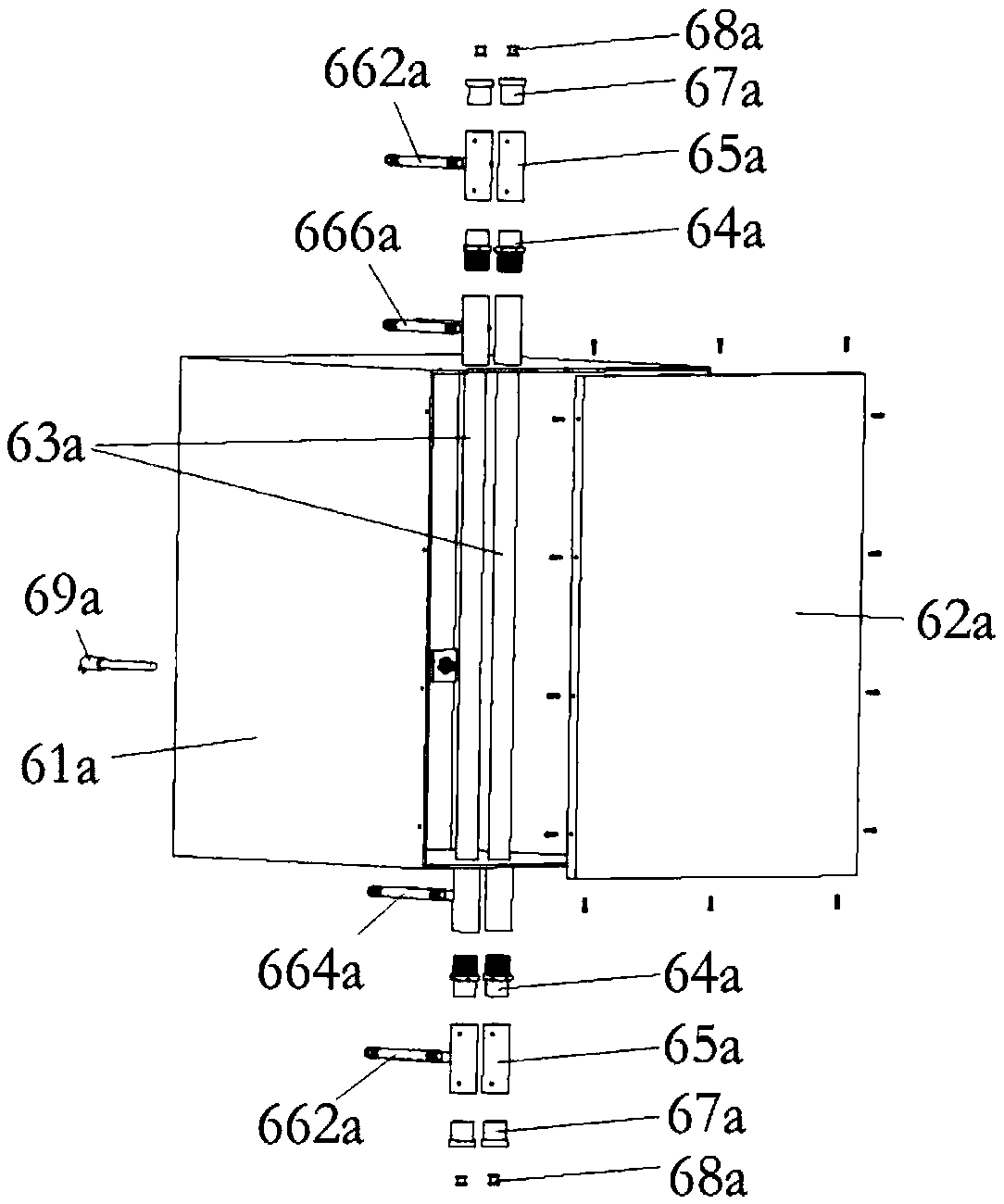

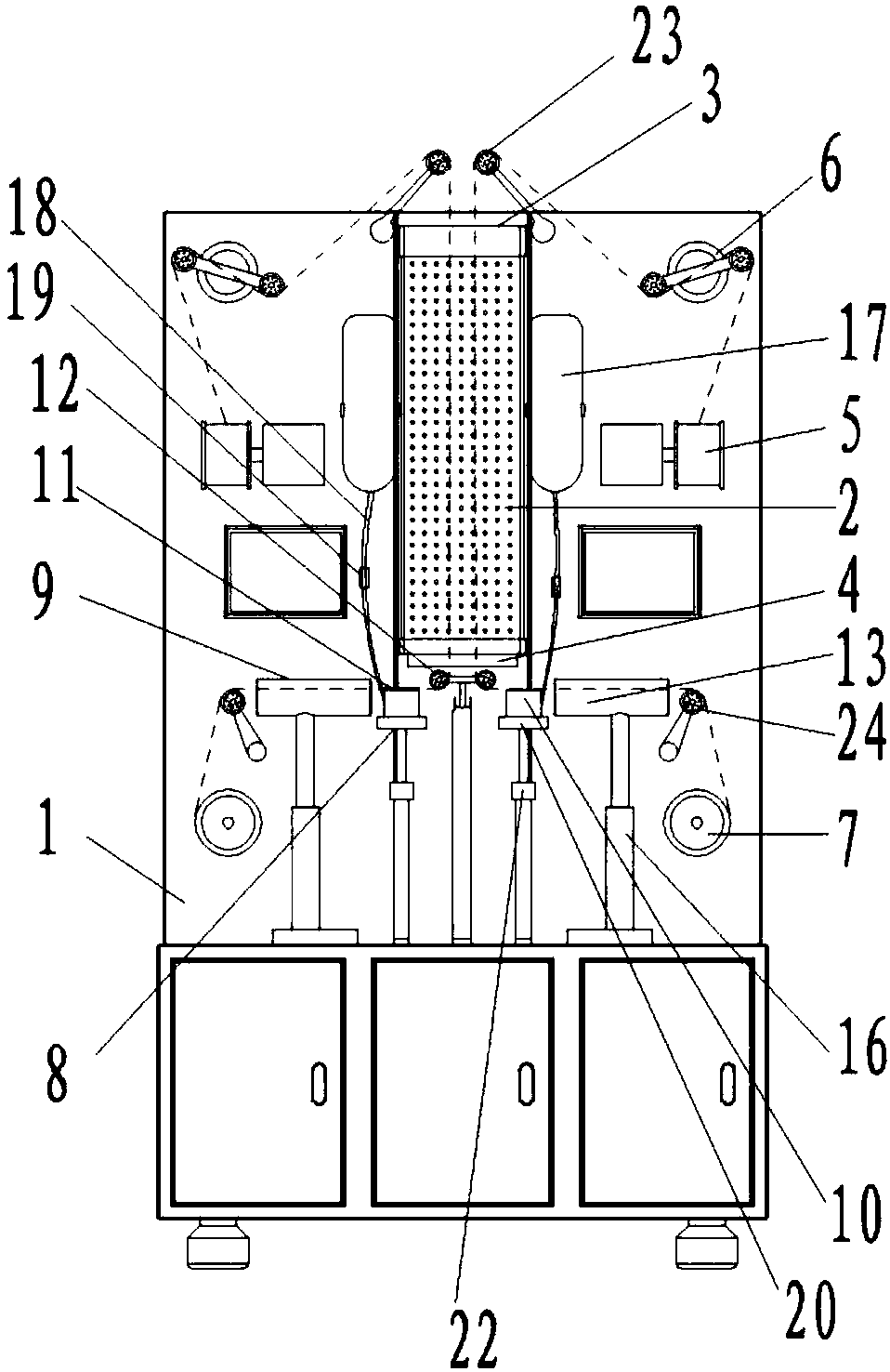

[0027] A vertical annealing furnace for bonding wires, comprising a frame 1 and an annealing assembly arranged on the frame 1, the annealing assembly includes a heating device 2, the heating device 2 is the prior art, for example, a quartz tube is used for heating , the heating device 2 is vertically arranged and the upper end is an inlet end 3, and the lower end is an outlet end 4, and the frame 1 is provided with a pay-off shaft 5 near the wire inlet end 3 of the heating device 2, and the pay-off shaft 5 and the wire-entry end 3 of the heating device 2 is also provided with a tension control assembly 6, and the frame 1 is provided with a take-up shaft 7 close to the wire-out end 4 of the heating device 2, and the annealing assembly also includes a 1 and a liquid cooling device 8 and an air-drying device 9 between the outlet end 4 of the heating device 2 and the take-up shaft 7, the liquid cooling device 8 includes a container 10 with an open upper end arranged on the frame 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com