Fixing clamp for large glass sheet transportation and storage

A technology for fixing clamps and glass, which is applied in the direction of transportation and packaging, conveyor objects, furnace components, etc. It can solve the problems of shaking and inability to play a buffering role, so as to prevent breakage, economic loss, and misalignment. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

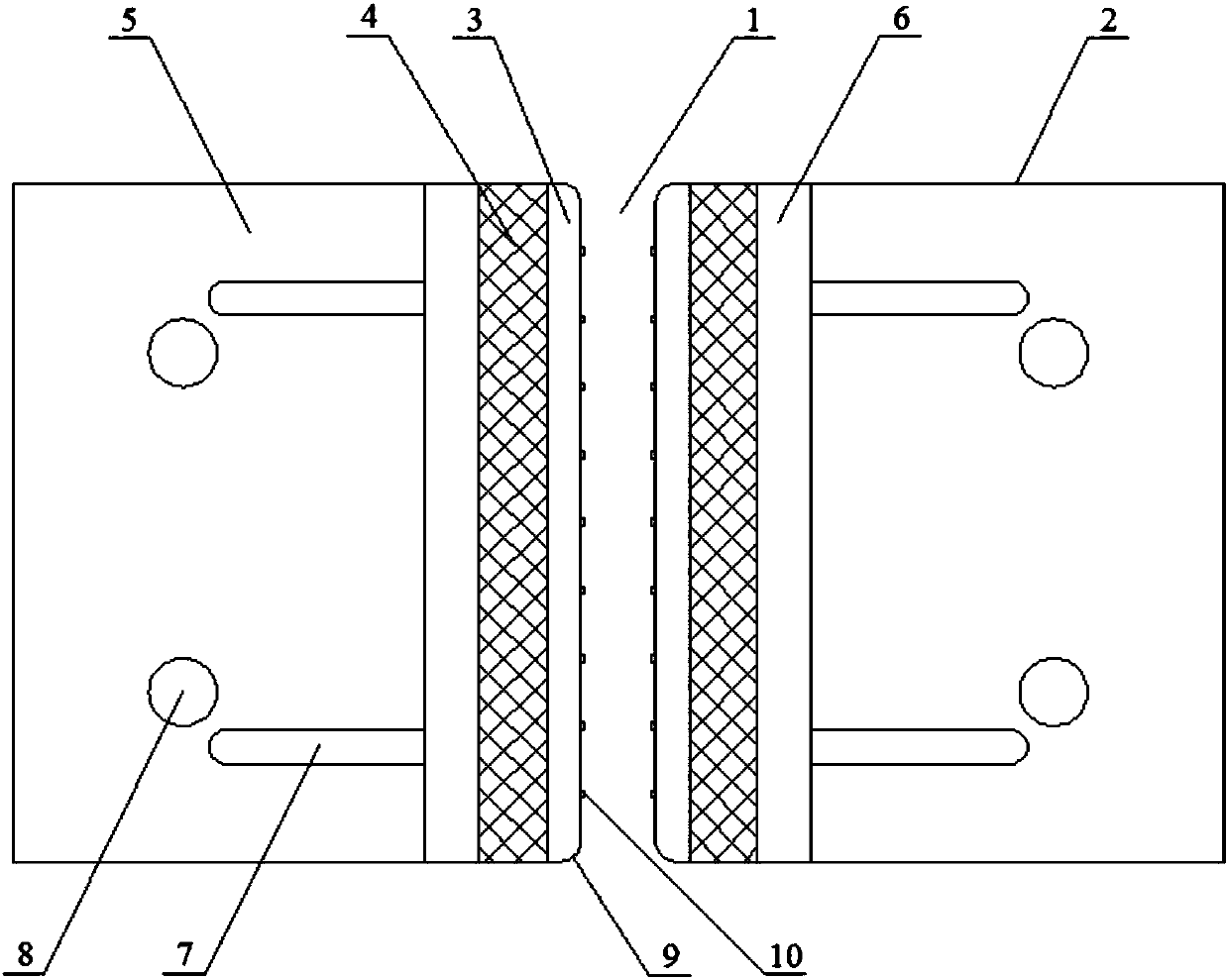

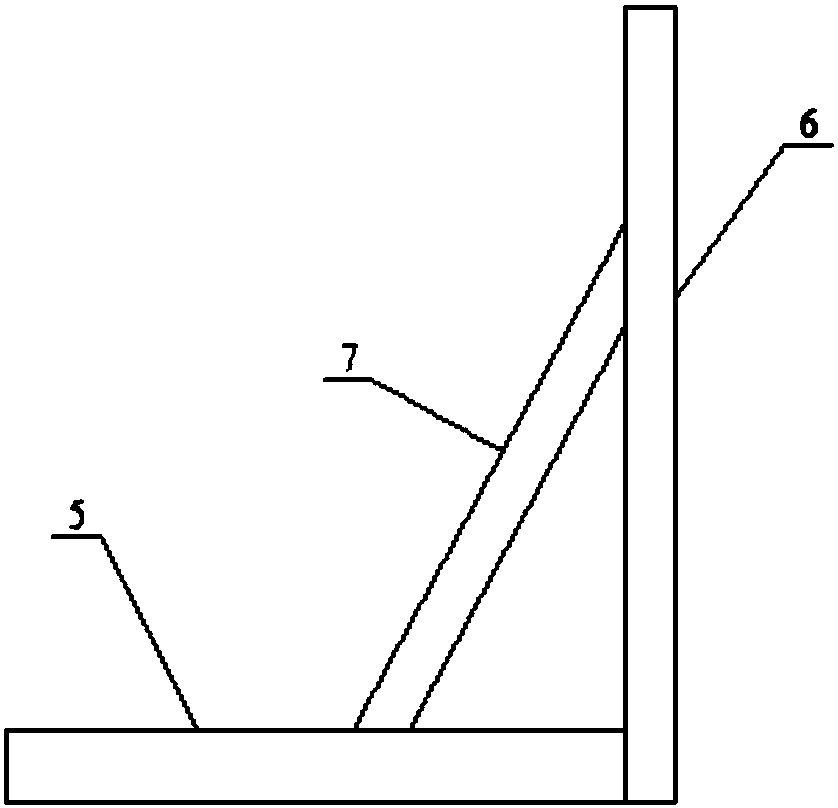

[0025] Such as figure 1 and figure 2 As shown, a fixed clip for transporting and storing a large piece of glass is composed of two symmetrically arranged clip halves, a reserved space 1 for glass fixing is provided between the two clip halves, and the clip halves include metal The support piece 2, the plastic contact piece 3 and the sponge buffer piece 4, the sponge cushion piece is arranged between the metal support piece and the plastic contact piece, the metal support piece is composed of the support bottom plate 5 and the support vertical plate 6 to form an L-shaped structure vertically, the support bottom plate and the A support rod 7 is arranged obliquely between the support vertical plates and a bolt installation through hole 8 is provided on the support base plate.

[0026] The end of the plastic contact is provided with an arc-shaped anti-collision angle 9, and plastic buffer particles 10 are uniformly arranged on the plastic contact, the plastic contact is made of ...

Embodiment 2

[0028] Such as figure 1 and figure 2 As shown, a fixed clip for transporting and storing a large piece of glass is composed of two symmetrically arranged clip halves, a reserved space 1 for glass fixing is provided between the two clip halves, and the clip halves include metal The support piece 2, the plastic contact piece 3 and the sponge buffer piece 4, the sponge cushion piece is arranged between the metal support piece and the plastic contact piece, the metal support piece is composed of the support bottom plate 5 and the support vertical plate 6 to form an L-shaped structure vertically, the support bottom plate and the A support rod 7 is arranged obliquely between the support vertical plates and a bolt installation through hole 8 is provided on the support base plate.

[0029] The end of the plastic contact is provided with an arc-shaped anti-collision angle 9, and plastic buffer particles 10 are uniformly arranged on the plastic contact, the plastic contact is made of ...

Embodiment 3

[0035] Such as figure 1 and figure 2 As shown, a fixed clip for transporting and storing a large piece of glass is composed of two symmetrically arranged clip halves, a reserved space 1 for glass fixing is provided between the two clip halves, and the clip halves include metal The support piece 2, the plastic contact piece 3 and the sponge buffer piece 4, the sponge cushion piece is arranged between the metal support piece and the plastic contact piece, the metal support piece is composed of the support bottom plate 5 and the support vertical plate 6 to form an L-shaped structure vertically, the support bottom plate and the A support rod 7 is arranged obliquely between the support vertical plates and a bolt installation through hole 8 is provided on the support base plate.

[0036] The end of the plastic contact is provided with an arc-shaped anti-collision angle 9, and plastic buffer particles 10 are uniformly arranged on the plastic contact, the plastic contact is made of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com