Styrene-free high-chemical-resistance ultraviolet-curing vinyl ester resin composition

A vinyl ester resin, chemical resistance technology, applied in the field of styrene-free high chemical resistance UV-curable vinyl ester resin composition, can solve the problem of low retention rate of mechanical properties and inability to satisfy vinyl ester unsaturated resin at the same time Toughness and chemical solvent corrosion resistance, etc., to achieve good chemical solvent resistance, improved chemical solvent resistance, and reduce odor and toxicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

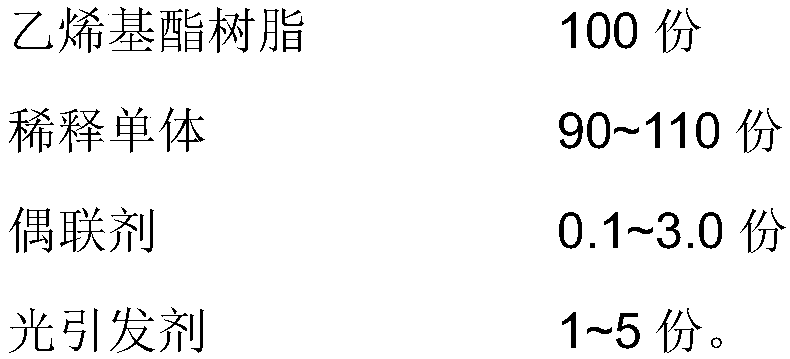

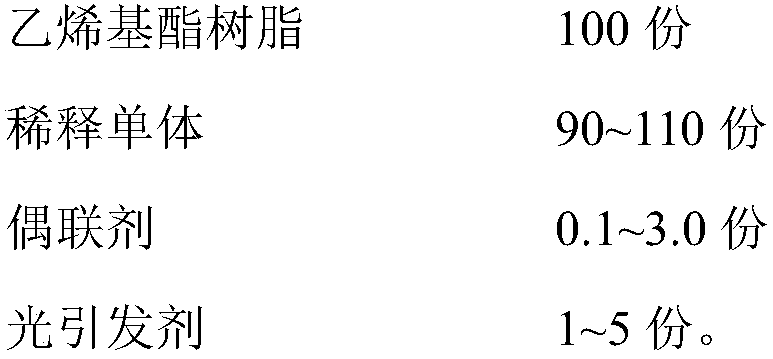

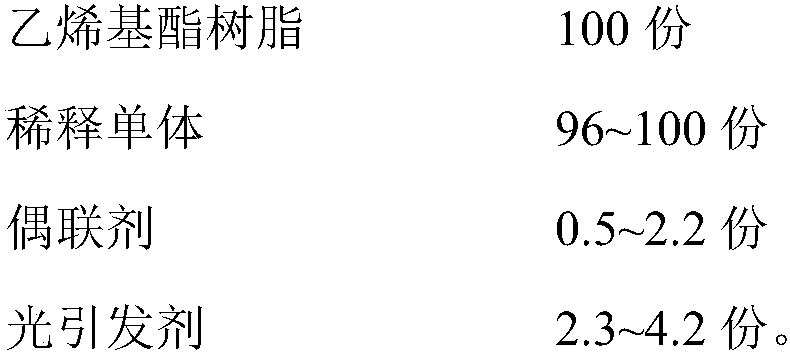

Method used

Image

Examples

Embodiment 1

[0024] Vinyl ester resin 901 produced by Wei (Shanghai) Fine Chemical Co., Ltd. is used as the matrix bisphenol A type-epoxy vinyl ester resin 100 parts, trimethylolpropane triacrylate (TMPTA) 20 parts, 1,6- 40 parts of ethylene glycol diacrylate (HDDA), 40 parts of methyl styrene (VT), 0.5 parts of coupling agent (Z-6030), 1.0 parts of photoinitiator (I-819) / (I-184) 3.0 disperse evenly with a high-speed mixer, and its viscosity at 25°C is 1800-2000cps; pour into the mold and irradiate with LED-UV (450W) for 10 minutes to complete the curing.

Embodiment 2

[0026] Vinyl ester resin 901-200 produced by Wei (Shanghai) Fine Chemical Co., Ltd. as the base is 100 parts of bisphenol A type epoxy vinyl ester resin, 30 parts of trimethylolpropane triacrylate (TMPTA), 1,6 - 50 parts of ethylene glycol diacrylate (HDDA), 20 parts of 2-hydroxyethyl methacrylate (HEMA), 2.0 parts of coupling agent (Z-6030), 1.0 parts of photoinitiator (I-819) / (I-184) 3.0 parts, disperse evenly with a high-speed mixer, and its viscosity at 25°C is 1500-1700cps; pour into the mold and irradiate with LED-UV (450W) for 10 minutes to complete the curing.

Embodiment 3

[0028] Vinyl ester resin 901-200 produced by Wei (Shanghai) Fine Chemical Co., Ltd. as the base is 100 parts of bisphenol A type epoxy vinyl ester resin, 30 parts of trimethylolpropane triacrylate (TMPTA), 1,6 - 40 parts of ethylene glycol diacrylate (HDDA), 10 parts of methyl styrene (VT), 20 parts of 2-hydroxyethyl methacrylate (HEMA), 2.0 parts of coupling agent (Z-6030), light Initiator (I-819) 1.0 parts / (I-184) 3.0 parts, disperse evenly with a high-speed mixer, and its viscosity at 25 ° C is 1300-1500 cps; pour it into the mold and irradiate it with LED-UV (450W) for 10 minutes Complete curing.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com