Method for preparation of superior grade potassium magnesium sulfate fertilizer from crude potassium chloride and crude picromerite

A technology of potassium-magnesium sulfate fertilizer and strontium ferrite, applied in the directions of potash fertilizer, application, inorganic fertilizer, etc., can solve problems such as potassium-free magnesium fertilizer, etc., and achieve the effects of easier operation, improved grade, and short process route

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

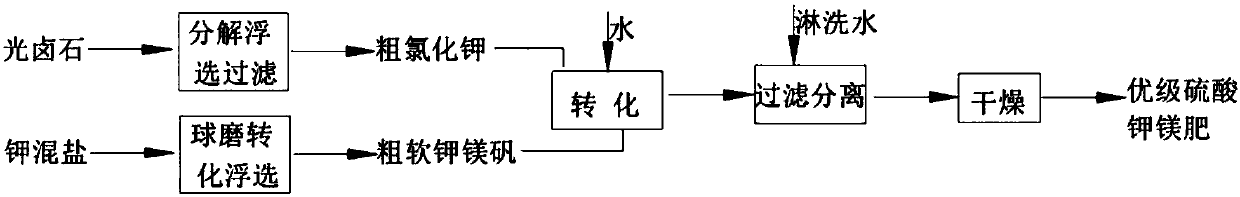

[0009] A kind of method that utilizes crude potassium chloride and coarse langbeinite to produce high-grade potassium magnesium sulfate fertilizer, such as figure 1 As shown, (1) Decomposition flotation section: Take carnallite ore and add it to the washing mother liquor, and decompose it in the environment of 23-27 ° C. After decomposition, Mg 2+ content ≥ 5.8wt%, adjust the slurry concentration to [20 ± 1]wt% for flotation, the obtained contains K + The crude potassium chloride with the content ≥ 22wt% is used as the raw material for the preparation of high-grade potassium magnesium sulfate fertilizer; the component of carnallite is: K + 6.0~8.5wt%, Mg 2+ 6.2~8.8wt%, Na + 5.0~8.5wt%, SO 4 2- 10.0~16.0wt%, Cl - (2) ball mill conversion flotation section: take potassium mixed salt ore and add water to ball mill, and the grinding concentration is controlled at 55~65wt%, so that the particle size in the potassium mixed salt after grinding is 100 mesh Some account for more ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com