Method for preparing wave-transmitting BN fiber toughened Si-B-N ceramic-based composite material through CVD/CVI

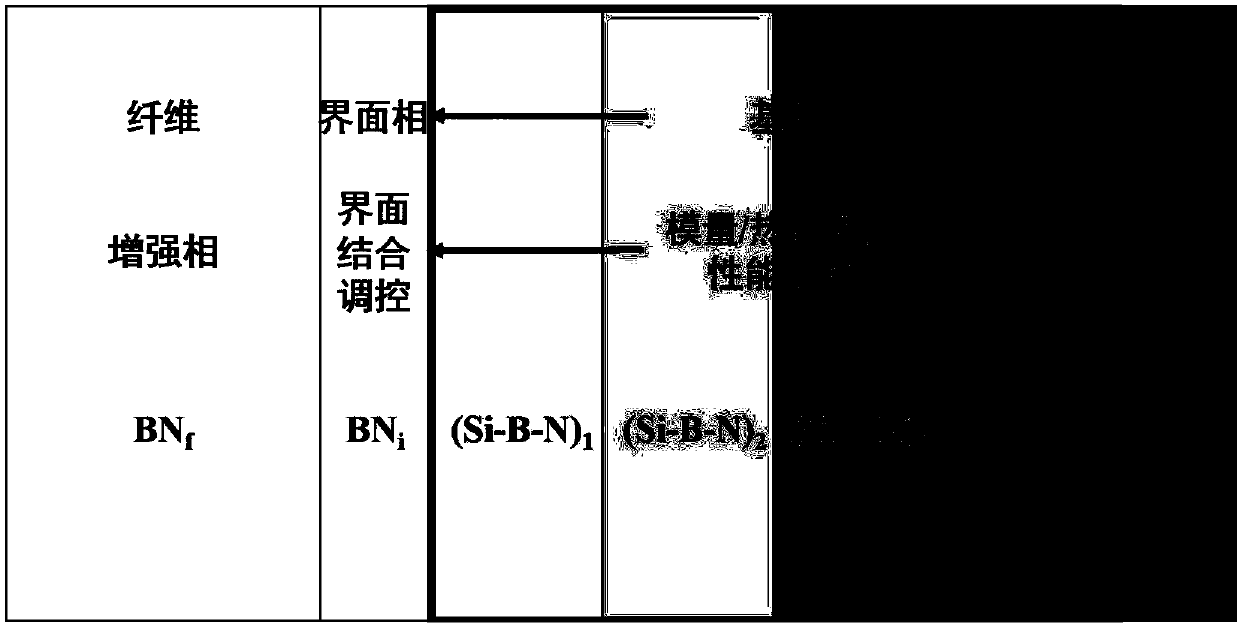

A fiber toughening and composite material technology, which is applied in the field of preparing wave-transmitting BN fiber toughening Si-B-N ceramic matrix composite materials by CVD/CVI method, can solve the fiber and matrix modulus and thermophysical properties mismatch, The wave-transmitting CFCC lacks interface control, and the cracks and pores are not continuous and dense enough to achieve the effects of regulation and optimization, realization of wave-transmitting properties and mechanical properties, and improvement of the mismatch of thermophysical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Step 1. Pretreatment of BN fiber preform. Divide 20 flat sheets into 10×10cm 2 The BN fiber cloth is soaked in xylene for 48 hours, then washed three times with xylene and three times with alcohol, and finally dried at 80°C to remove the adhesive layer.

[0035] Step 2. Preparation of BN interface. Lay the degummed BN fiber cloth in a graphite fixture to form a two-dimensional prefabricated body, and hang the prefabricated body in the isothermal zone of the deposition furnace. The deposition process parameters of the BN interface are: BCl 3 The flow rate is 100ml / min, NH 3 The flow rate is 300ml / min, H 2 The flow rate is 500ml / min, the Ar flow rate is 500ml / min, the furnace pressure is 1kPa, the deposition temperature is 650°C, the deposition time is 50h, and the thickness of the BN interface is 1500nm. Then, the BN fiber preform containing the BN interface was placed in a high temperature furnace for heat treatment, the treatment temperature was 1300°C, and the tr...

Embodiment 2

[0039] Step 1. Pretreatment of BN fiber preform. Entrust the fiber weaving unit to weave BN fiber bundles into a fiber prefabricated body with a two-dimensional and a half structure. Soak the two-dimensional semi-BN fiber prefabricated body in xylene for 48 hours, wash it three times with xylene and three times with alcohol, and finally dry it at 80°C to remove the glue layer.

[0040] Step 2. Preparation of BN interface. Hang the degummed two-dimensional semi-BN fiber preform in the isothermal zone of the deposition furnace. The deposition process parameters of the BN interface are: BCl 3 The flow rate is 100ml / min, NH 3 Flow rate is 300ml / min, Ar flow rate is 500ml / min, H 2 The flow rate is 500ml / min, the pressure in the furnace is 1kPa, the deposition temperature is 650°C, the deposition time is 40h, and the interface thickness of the prepared BN is 1000nm. Then, the BN fiber preform containing the BN interface was placed in a high temperature furnace for heat treatmen...

Embodiment 3

[0044] Step 1. Pretreatment of BN fiber preform. Entrust the fiber weaving unit to weave BN fiber bundles into a fiber prefabricated body with a three-dimensional four-way structure. Soak the three-dimensional four-way BN fiber prefabricated body in xylene for 48 hours, then wash it three times with xylene and three times with alcohol, and finally dry it at 80°C to remove the glue layer.

[0045] Step 2. Preparation of BN interface. Hang the three-dimensional four-directional BN fiber preform after degumming in the isothermal zone of the deposition furnace. The deposition process parameters of the BN interface are: BCl 3 The flow rate is 100ml / min, NH 3 Flow rate is 300ml / min, Ar flow rate is 500ml / min, H 2 The flow rate is 500ml / min, the pressure in the furnace is 1kPa, the deposition temperature is 750°C, the deposition time is 15h, and the interface thickness of the prepared BN is 800nm. Then, the BN fiber preform containing the BN interface was placed in a high temper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com