Dismounting device

A technology for disassembling devices and impact parts, which is applied in the direction of hand-held tools and manufacturing tools, which can solve the problems of inconvenient disassembly, heavy weight, and large dimensions of blind mating components, shorten maintenance and repair time, reduce labor costs, The effect of easy disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the technical solutions and advantages of the present application clearer, the exemplary embodiments of the present application will be described in further detail below with reference to the accompanying drawings. Obviously, the described embodiments are only a part of the embodiments of the present application, rather than all implementations. Exhaustive list of examples. And if there is no conflict, the embodiments in this description and the features in the embodiments can be combined with each other.

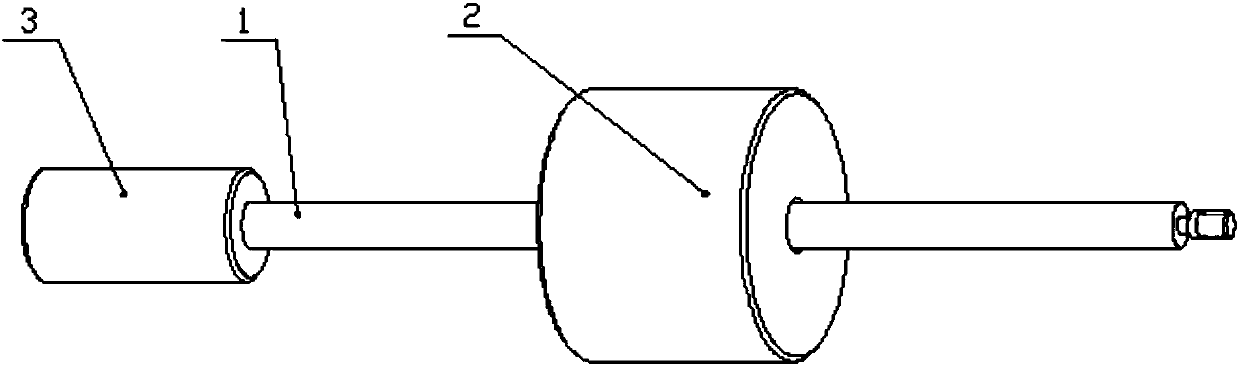

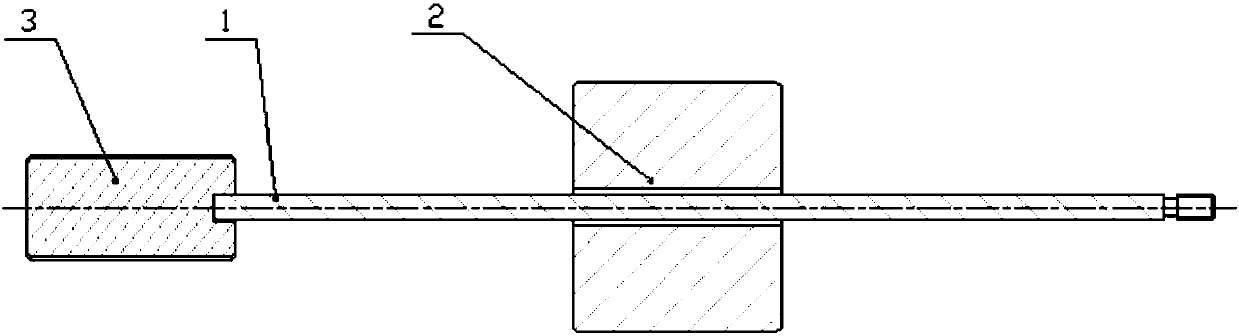

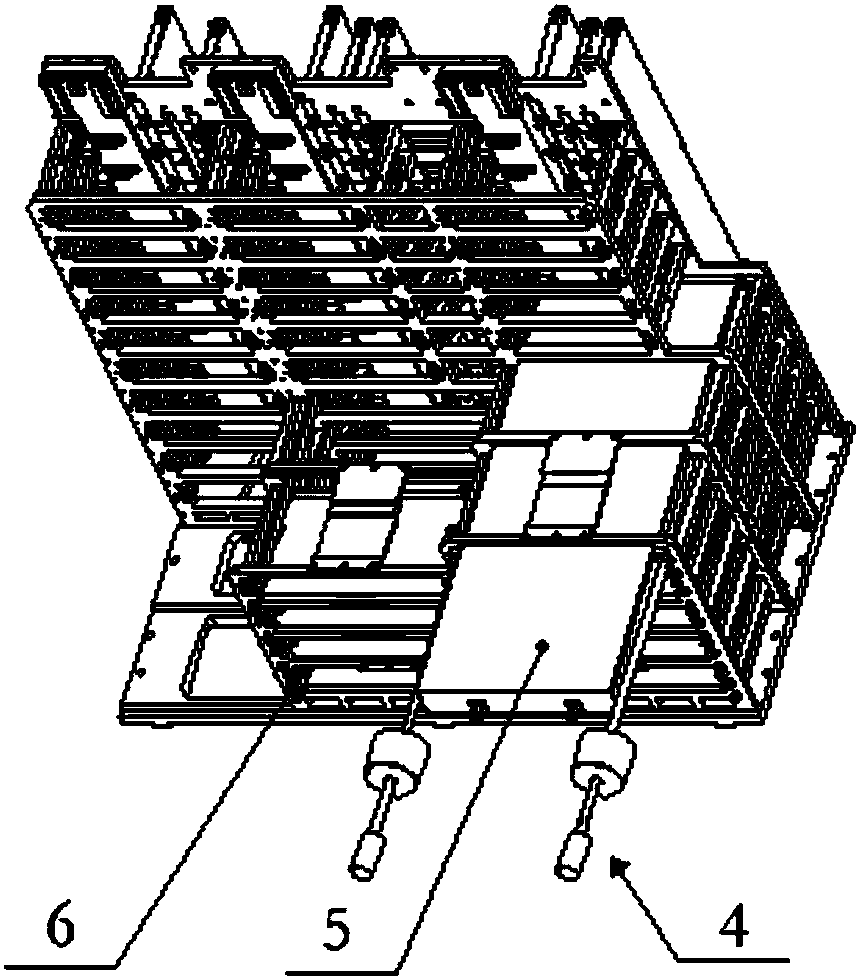

[0026] The core idea of this solution is to use the principle of inertial impact, through the rapid sliding of the impact part 2 and the inertial impact force of the limit part 3, to overcome the static friction of the blind-mate device and the frame 6, or the heavier disassembled device 5 The dislocation friction force caused by the inclination generated when sliding on the long-distance guide rail causes the disassembled device 5 to be detached from...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com