Projection welding device and welding method for flying ring of vibration absorber

A welding method and shock absorber technology, applied in welding equipment, resistance welding equipment, metal processing equipment and other directions, can solve the problems of increasing product man-hours, long time spent, electrode protection measures, etc., to improve processing efficiency and save costs. , Welding firm effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

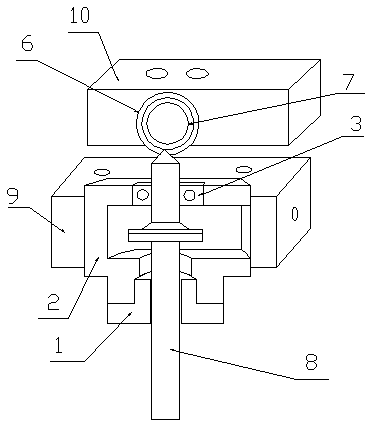

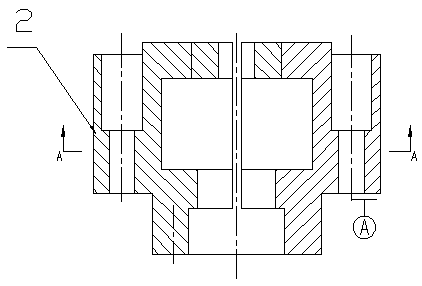

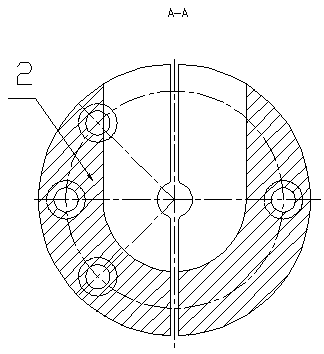

[0039] This embodiment provides a kind of shock absorber suspension ring projection welding device, refer to figure 1 , including a first clamping mechanism and a second clamping mechanism arranged on the projection welding machine; the first clamping mechanism includes an upper electrode block 6, an upper electrode top block 10 arranged on the upper electrode block 6 and The first hydraulic cylinder connected with the upper electrode top block 10, the structure of the upper electrode block 6 refers to Figure 10; The second clamping mechanism includes a lower electrode block 2, a lower electrode top block 9 arranged on the lower electrode block 2 and a second hydraulic cylinder connected with the lower electrode top block 9, the lower electrode The structure of block 2 see figure 2 and image 3 , the upper end of the lower electrode top block 9 is provided with an inlay block 3, and the structure of the inlay block 3 refers to Figure 5 and Figure 6 , the lower end of t...

Embodiment 2

[0045] refer to figure 1 , The projection welding device for suspension rings of the shock absorber provided in this embodiment is an improvement on the basis of Embodiment 1: the material of the clamping block 1 is nylon. The material of the insert 3 is tungsten copper. Tungsten copper has good electrical and thermal conductivity, high hardness, wear resistance, and easy processing. The chrome copper used in the upper electrode block 6 and the lower electrode block 2 has good electrical and thermal conductivity and is wear-resistant.

Embodiment 3

[0047] The shock absorber ring projection welding device provided in this embodiment is an improvement on the basis of the second embodiment: a position sensor is arranged in front of the top block of the upper electrode. A screw is arranged on one side of the lower electrode top block.

[0048] Adjust the opening and tightening of the top block through the two position sensors in front of the top block of the upper electrode, and adjust the screw so that the convex point is in the middle of the lifting ring, so as to prevent the loosening of the lifting ring and cause the unqualified symmetry of the replacement after projection welding, which will cause the workpiece to be scrapped .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com