Low-cost container top plate hydraulic forming system

A hydraulic forming and container technology, which is applied in the field of hydraulic presses, can solve the problems of high procurement costs, achieve good synchronization, improve processing efficiency, and move smoothly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

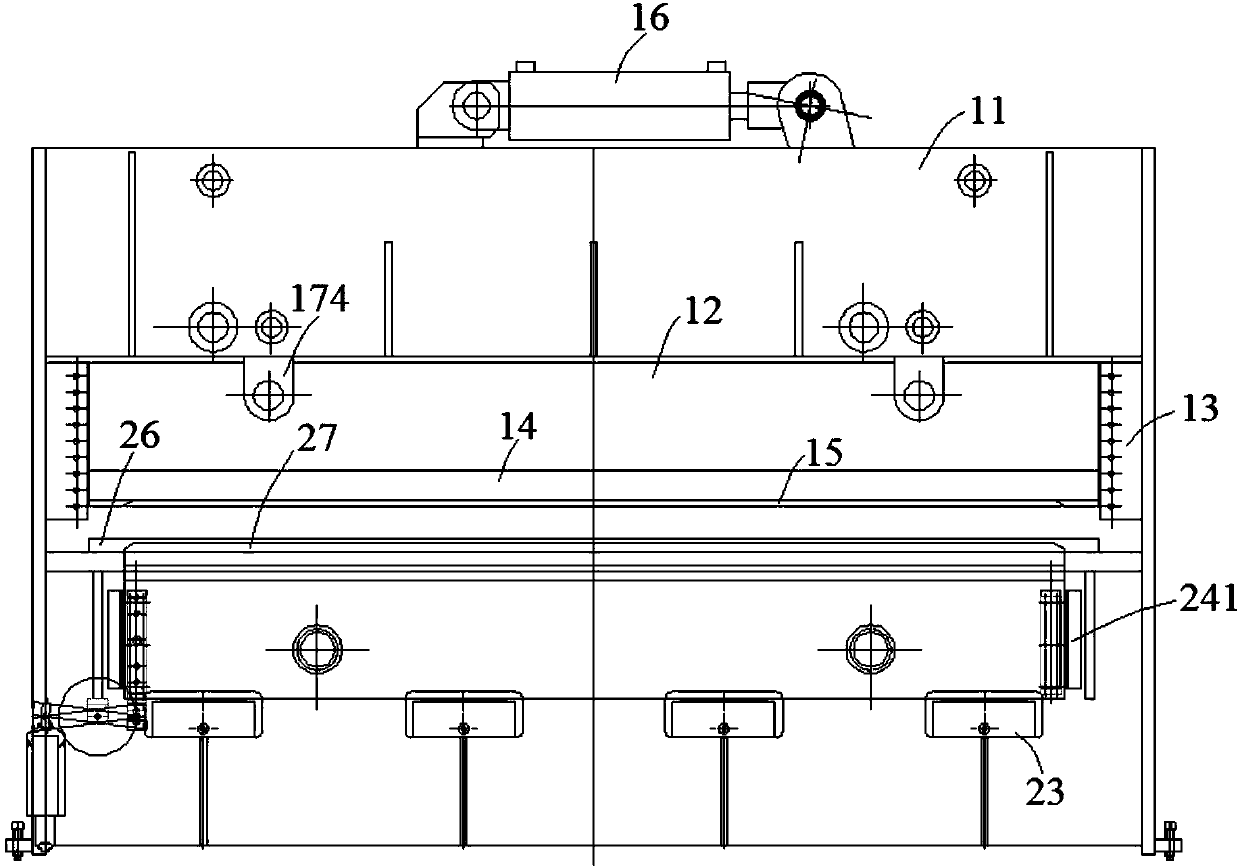

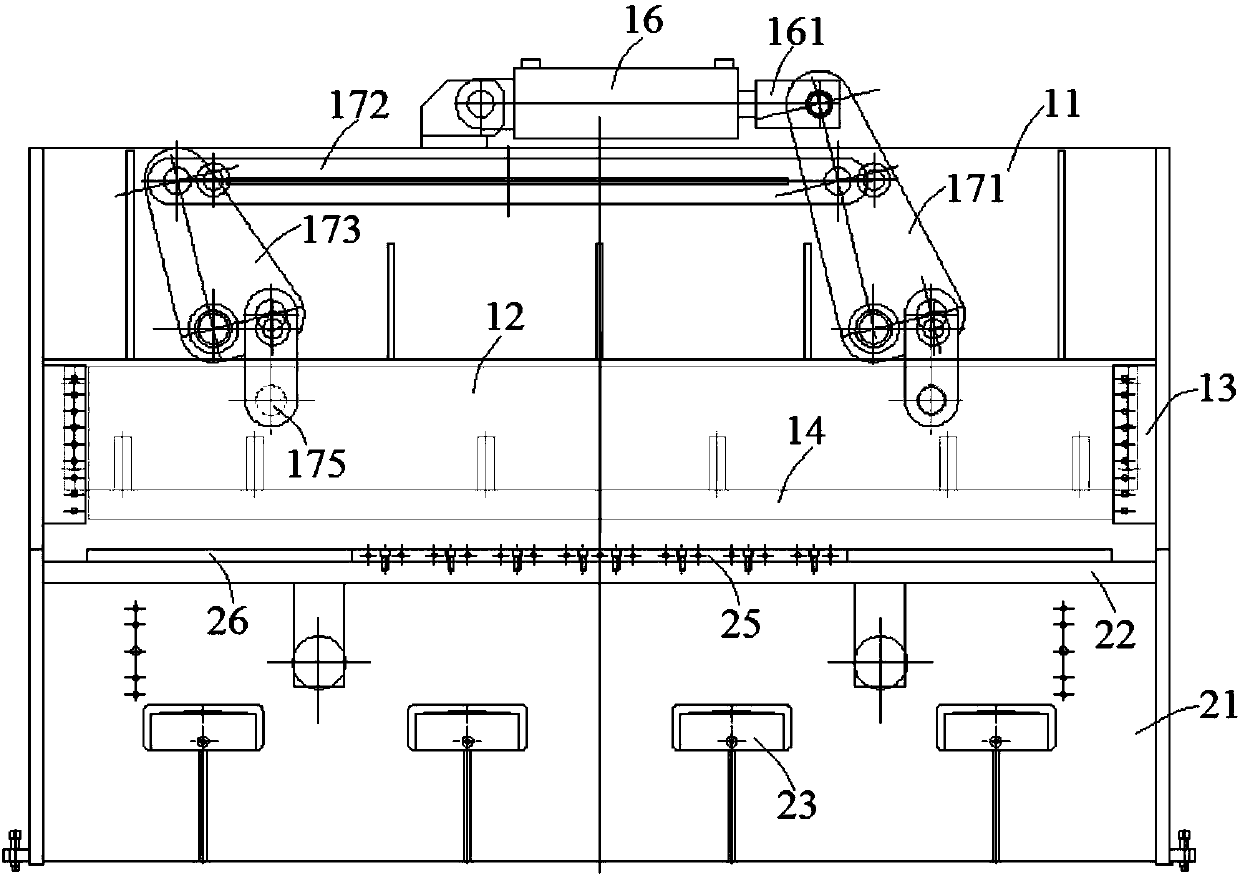

[0037] Combine figure 1 with image 3 , A low-cost container roof hydraulic forming system of this embodiment includes an upper box body 11, an upper slide block 12, an upper mold 15, an upper main cylinder 16, a lower box body 21, a lower main cylinder 23, a lower slide block 24 and Lower mold 27. The upper master cylinder 16 is arranged on the upper part of the upper box body 11, the upper sliding block 12 is arranged on the lower part of the upper box body 11, the bottom of the upper sliding block 12 is arranged with an upper mold base 14, and the upper mold 15 is fixed on the upper mold base 14.

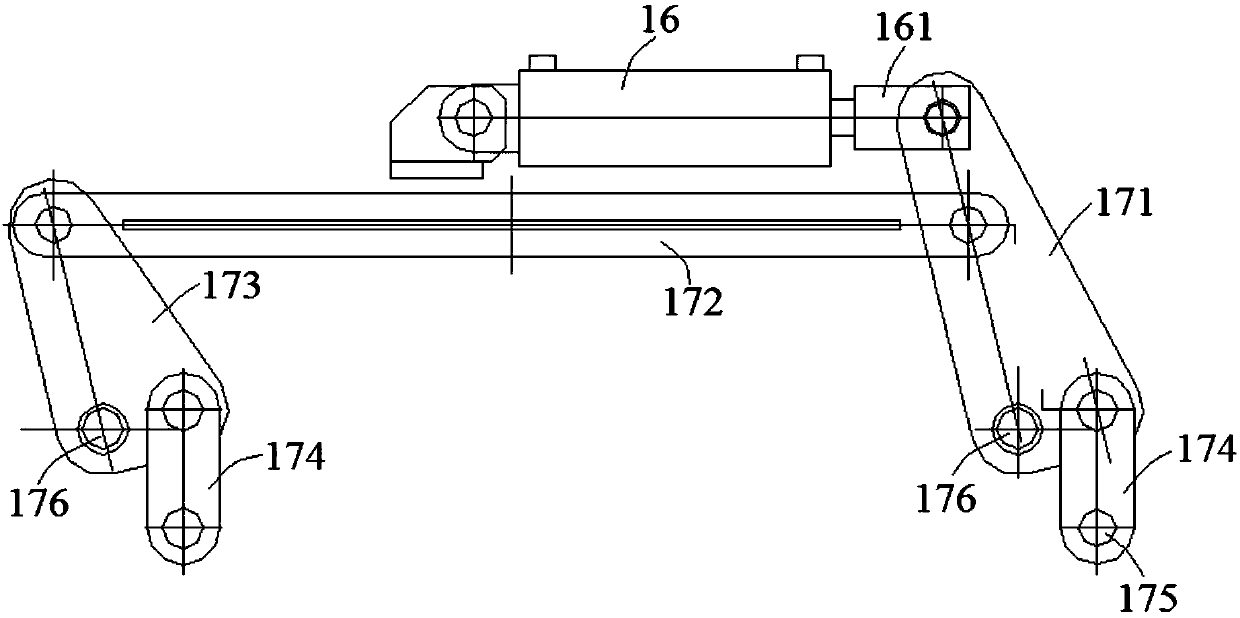

[0038] A drive unit is provided between the upper main cylinder 16 and the upper sliding block 12, which combines figure 2 The driving unit includes a main swing rod 171, a cross beam 172, an auxiliary swing rod 173 and a vertical link 174. One end of the cross beam 172 is axially connected with the main swing rod 171, and the other end is axially connected with the auxiliary swing...

Embodiment 2

[0043] Combine Figure 5 , Image 6 , Figure 7 with Picture 8 A low-cost container roof hydroforming system of this embodiment is basically the same as Embodiment 1, and the difference is that this embodiment further optimizes the design of the upper mold 15, the lower mold 27 and the blank holder 26, specifically: The upper mold 15 is set as a female mold, and threaded holes are arranged around the cavity of the female mold. The female mold is inserted into the threaded holes by bolts and is connected to the upper mold base 14 at the lower part of the upper sliding block 12. The lower mold 27 is a convex mold, and threaded holes are provided along the length direction of the lower mold 27, and the lower mold 27 is inserted into the threaded holes by bolts to be connected to the lower sliding block 24. The upper mold 15, the blank holder 26 and the lower mold 27 are all designed with a large arc structure along the length direction.

[0044] It is worth noting that in the init...

Embodiment 3

[0046] The low-cost container roof hydraulic forming system of this embodiment is basically the same as that of the second embodiment. The difference is that the thickness L1 at the highest point of the large arc surface in the longitudinal direction of the blank holder 26 in this embodiment is the same as the thickness at the lowest point. The difference in L2 is 14.2 mm. The thickness difference L3 between the highest point and the lowest point of the small arc surface of the blank holder 26 in the width direction is 3.5 mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com