Environment-friendly organic-inorganic compound fertilizer and preparation method thereof

A compound fertilizer and organic technology, applied in fertilizer mixtures, fertilization devices, applications, etc., can solve the problems of low utilization rate and easy immobilization of phosphorus, so as to improve utilization rate, enhance plant stress resistance, reduce The effect of financial burden

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

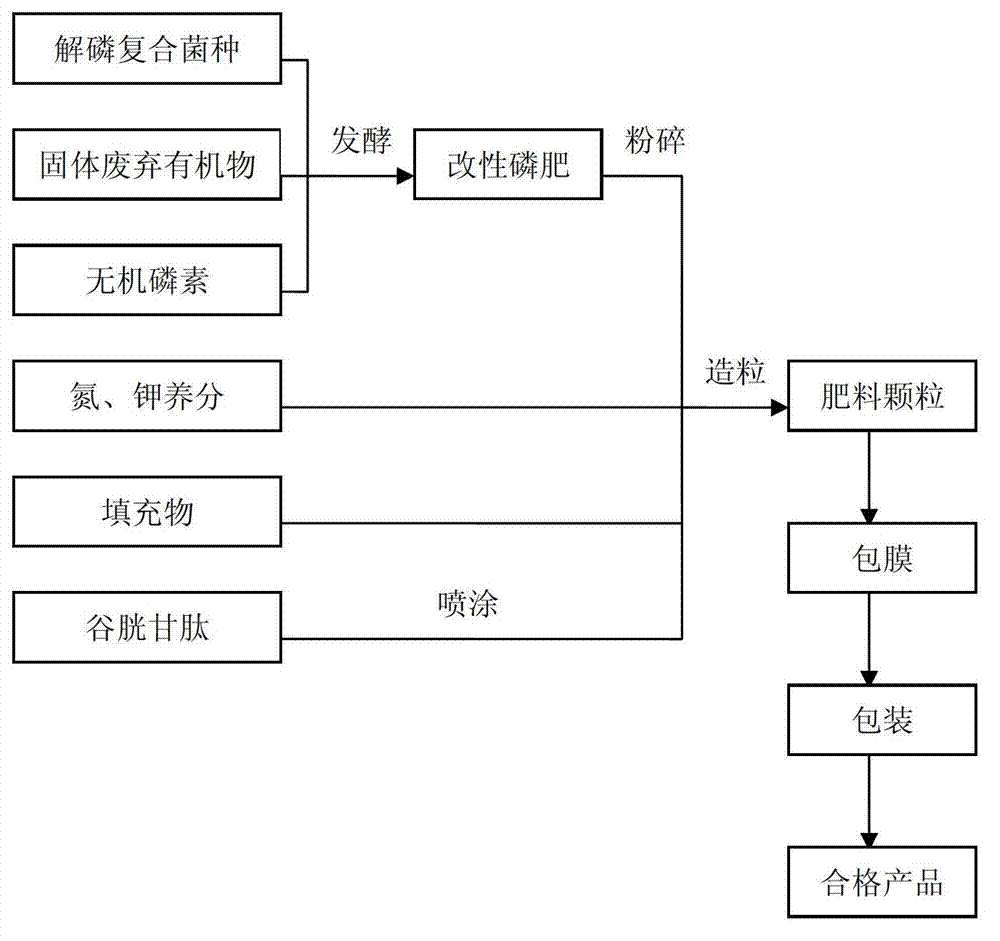

Method used

Image

Examples

Embodiment 1

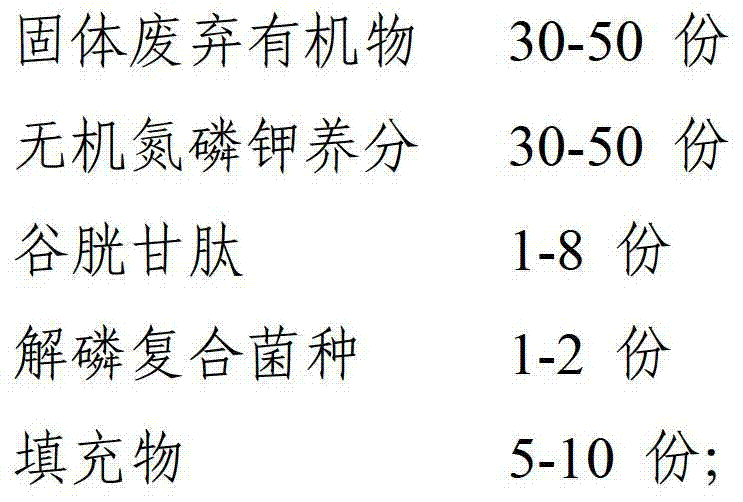

[0030] The organic-inorganic compound fertilizer, in parts by weight, has the following raw material components:

[0031] Mushroom residue 15, furfural residue 15, plant ash 8, alfalfa residue 2, urea 15, monoammonium phosphate 15, potassium sulfate 10, glutathione 8, Bacillus megaterium 0.5, Escherichia coli 0.5, Bacillus jelly-like 0.5, Pseudomonas fluorescens 0.5, diatomaceous earth 10. The mushroom slag is the retting mushroom slag. Add water to the mushroom slag to reach 70% of the maximum water holding capacity, pile it up, cover it with a plastic film, pile it for 4 months, and spread it out to air dry.

[0032]The strains used in the examples of the present invention were all purchased from the China Industrial Microbiology Culture Collection Center (CICC). A large number of strains were obtained through fermentation and amplification, and were used after being adsorbed by a carrier. Among them, the preservation number of Bacillus megaterium is CICC23048; the preserva...

Embodiment 2

[0039] The organic-inorganic compound fertilizer has the following raw material components in parts by weight:

[0040] Mushroom residue 15, furfural residue 15, plant ash 8, grape meal 2, urea 15, monoammonium phosphate 10, potassium sulfate 10, potassium chloride 5, glutathione 8, Bacillus megaterium 0.5, Escherichia coli 0.5, Bacillus jelly-like 0.5, Pseudomonas fluorescens 0.5, bentonite 10.

[0041] production method:

[0042] (1) Mixing and fermentation of raw materials: put plant ash first, then put mushroom dregs, furfural dregs, alfalfa dregs and monoammonium phosphate into the mixer, add Bacillus megaterium, Escherichia coli, jelly-like spores Bacillus and Pseudomonas fluorescens are stirred evenly, piled up in the plant for solid fermentation, sprinkled with water every two days, and keep the moisture content at 35%, and use a turner to turn over and throw the material to avoid excessive internal temperature of the material. After 10 days, the fermentation ends, a...

Embodiment 3

[0047] Organic-inorganic compound fertilizer, the raw material components in parts by weight are as follows:

[0048] Mushroom residue 10, furfural residue 10, plant ash 12, chicken manure 8, urea 15, monoammonium phosphate 10, potassium sulfate 5, potassium chloride 10, glutathione 8, Bacillus megaterium 1, Bacillus jelly-like 0.5, Pseudomonas fluorescens 0.5, diatomaceous earth 10.

[0049] production method:

[0050] (1) Mixing and fermentation of raw materials: put plant ash first, then put mushroom slag, furfural slag, chicken manure and monoammonium phosphate into the mixer, add Bacillus megaterium, Bacillus jellylike, Pseudomonas fluorescens Stir the bacteria evenly, stack them in the plant for solid fermentation, sprinkle water once every two days, keep the moisture content at 30%, and use a turning machine to turn over and throw the material to avoid excessive internal temperature of the material. After 8 days, the fermentation ends, and the organic modified phospha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com