Furfural hydrogenation catalyst, preparation method and applications thereof, and method for preparing furfuryl alcohol through liquid-phase hydrogenation of furfural

A technology of hydrogenation catalysts and additives, which is applied in the direction of catalyst activation/preparation, metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, etc., and can solve the problem of a large amount of copper metal, high consumption, and increased catalyst costs, etc. problem, achieve the effect of stabilizing the reactive center, changing the coordination environment, and promoting surface enrichment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

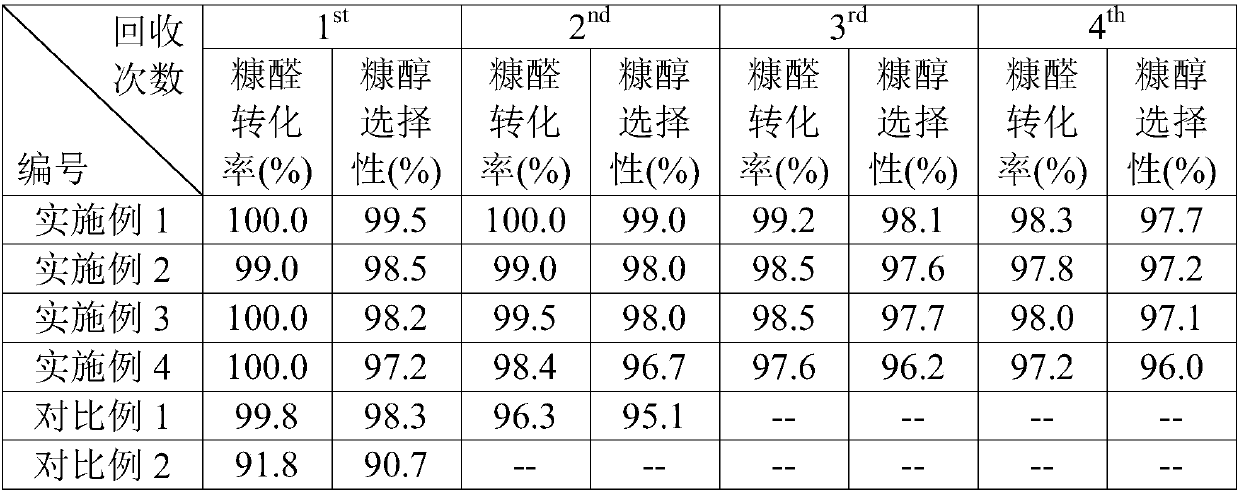

Examples

Embodiment 1

[0055] Weigh Cu(NO 3 ) 2 ·3H 2 O 120g, 25wt% acidic silica sol (pH=2.5) 70g and ZrOCl 2 ·8H 2 O13.4g is stirred and dissolved in 500mL deionized water after mixing to obtain mixed solution A; the preparation concentration is 1mol / L Na 2 CO 3 Aqueous solution B; put 100mL of deionized water into the reaction kettle, under the conditions of constant stirring and a reaction temperature of 60°C, add the mixed solution A and the aqueous solution B in parallel, wherein the amount of the aqueous solution B is to make the reaction system The pH value was kept at 7, and after the addition was completed, continue to stir at 60°C for 0.5h to carry out the coprecipitation reaction. The above-mentioned coprecipitation product was filtered and washed with deionized water, then dried at 120°C for 12h, and then placed in a muffle furnace in Roast at 300°C for 4 hours, and finally grind the product obtained above to obtain a hydrogenation catalyst. The particle size of the hydrogenation ...

Embodiment 2

[0060] Weigh Cu(NO 3 ) 2 ·3H 2 O 120g, 25wt% acidic silica sol (pH=2.5) 60g and ZrOCl 2 ·8H 2 O11.3g is stirred and dissolved in 500mL deionized water after mixing to obtain mixed solution A; the preparation concentration is 1mol / L Na 2 CO 3 Aqueous solution B; put 100mL of deionized water into the reaction kettle, under the conditions of constant stirring and a reaction temperature of 60°C, add the mixed solution A and the aqueous solution B in parallel, wherein the amount of the aqueous solution B is to make the reaction system The pH value was kept at 7, and after the addition was completed, continue to stir at 60°C for 0.5h to carry out the coprecipitation reaction. The above-mentioned coprecipitation product was filtered and washed with deionized water, then dried at 120°C for 12h, and then placed in a muffle furnace in Roast at 300°C for 4 hours, and finally grind the product obtained above to obtain a hydrogenation catalyst. The particle size of the hydrogenation ...

Embodiment 3

[0065] Weigh Cu(NO 3 ) 2 ·3H 2 O 120g, 25wt% acidic silica sol (pH=2.5) 84g and ZrOCl 2 ·8H 2 O13.7g is stirred and dissolved in 500mL deionized water after mixing to obtain mixed solution A; the preparation concentration is 1mol / L Na 2 CO 3 Aqueous solution B; put 100mL of deionized water into the reaction kettle, under the conditions of constant stirring and a reaction temperature of 60°C, add the mixed solution A and the aqueous solution B in parallel, wherein the amount of the aqueous solution B is to make the reaction system The pH value was kept at 7, and after the addition was completed, continue to stir at 60°C for 0.5h to carry out the coprecipitation reaction. The above-mentioned coprecipitation product was filtered and washed with deionized water, then dried at 120°C for 12h, and then placed in a muffle furnace in Roast at 300°C for 4 hours, and finally grind the product obtained above to obtain a hydrogenation catalyst. The particle size of the hydrogenation ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com