Aluminum alloy template special for beam-column cast-in-place node of assembled concrete frame structure

A technology of aluminum alloy formwork and frame structure, which is applied to the preparation of formwork/formwork components, formwork/formwork/work frames, and building components on site. Guarantee, unreliable splicing quality between boards, etc., to achieve the effect of good compactness, enhanced fastening effect, and simple installation and construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

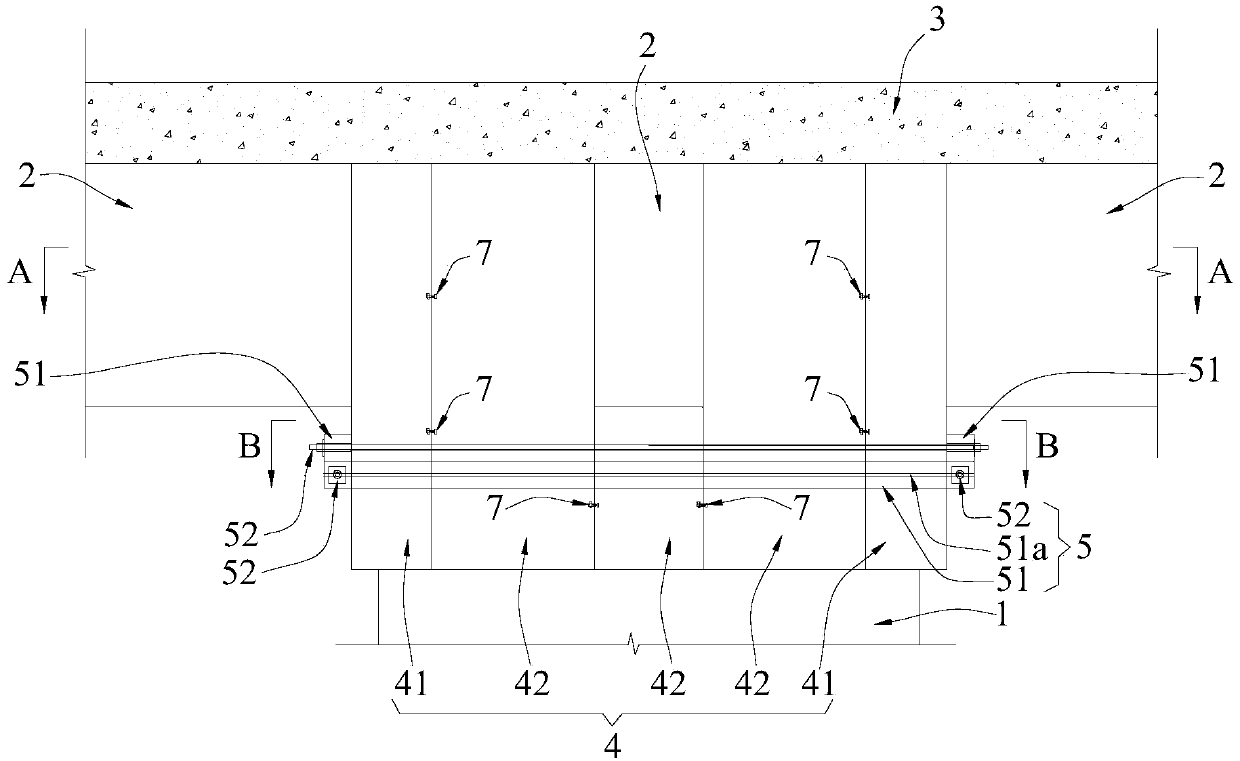

[0049] As a preferred embodiment of the present invention: the inner surface of the aluminum alloy sleeve member 4 and the frame column prefabricated part 1 is provided with a groove, and the groove is filled with a rubber layer 6 . Therefore, by utilizing the characteristics of strong compressibility and good compactness of the rubber layer 6, the present invention can strengthen the fastening effect of the column hoop 5 on the aluminum alloy sleeve member 4 without affecting the size of the beam-column cast-in-place node. The gap between the aluminum alloy sleeve member 4 and the frame column prefabricated part 1 is blocked to effectively prevent concrete from leaking during the pouring process.

[0050] As a preferred embodiment of the present invention: the aluminum alloy plates that make up the aluminum alloy sleeve member 4 include several standardized L-shaped aluminum alloy plates 41 and several standardized aluminum alloy flat plates 42, wherein the L-shaped aluminum a...

Embodiment 1

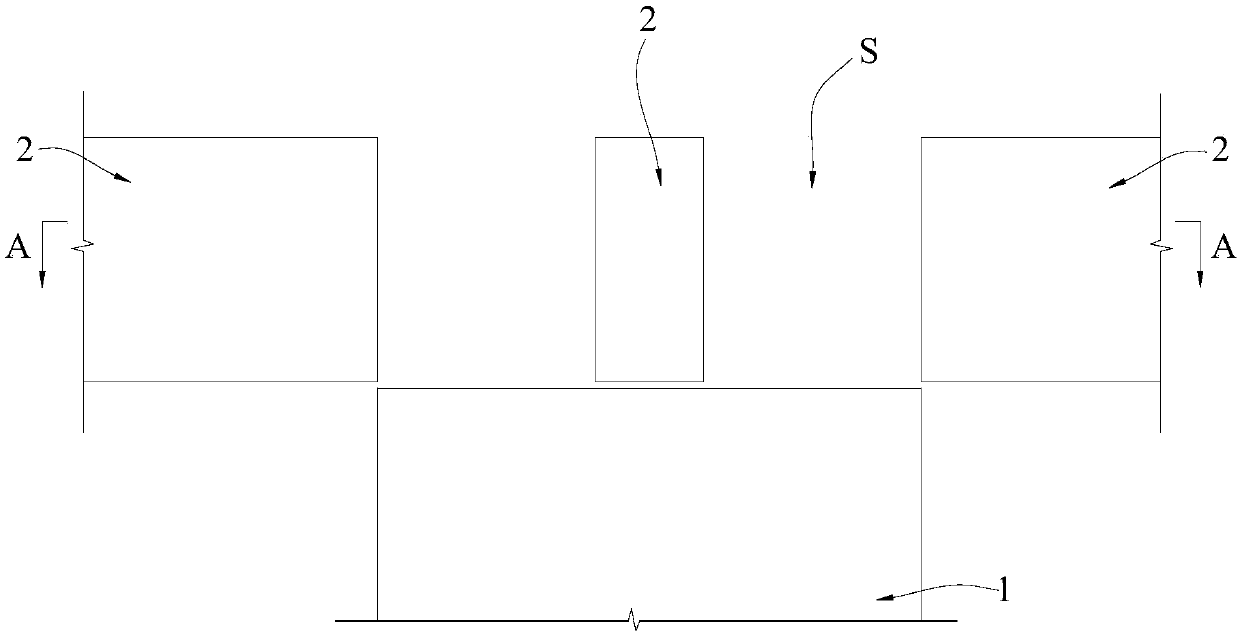

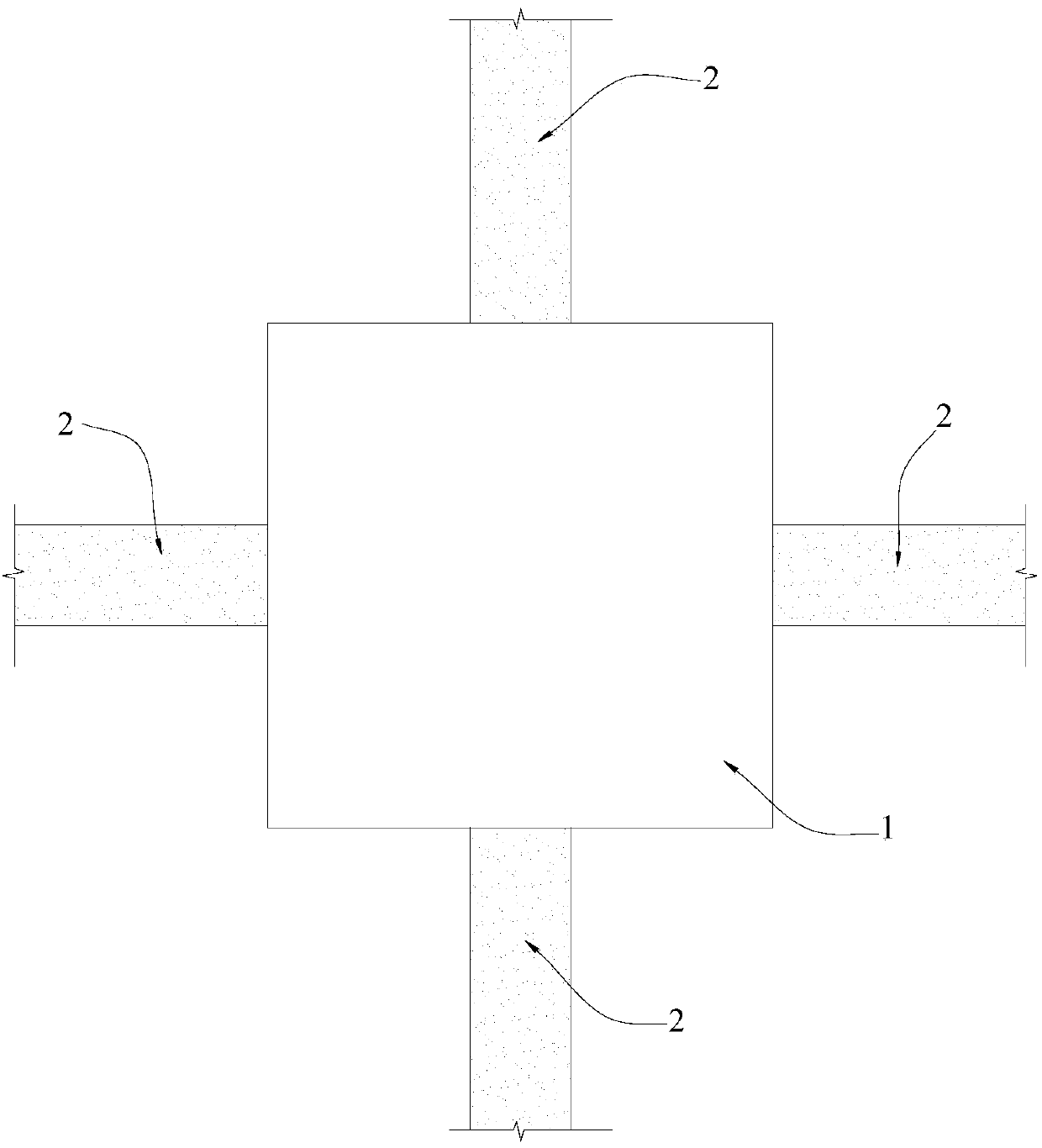

[0055] Such as Figure 1 to Figure 5 As shown, when the frame column prefabricated part 1 is a center column, the concrete pouring area S is located between the top surface of the center column and the end surfaces of the four frame beams 2, and the four frame beams 2 are respectively located on the four sides of the center column. side, and the four frame beams 2 all belong to the situation that their side faces and end faces are not respectively flush with the two sides of a certain corner of the frame column prefabricated part 1;

[0056] Embodiment 1 of the present invention is based on the above-mentioned inventive concept and the above-mentioned preferred structure, and adopts the following specific scheme: the upper end of the aluminum alloy sleeve member 4 is provided with four notches 4a corresponding to the four frame beams 2 respectively.

Embodiment 2

[0058] Such as Figure 6 to Figure 10 As shown, when the prefabricated part 1 of the frame column is a side column, the concrete pouring area S is located between the top surface of the side column and the end surfaces of the three frame beams 2, and the three frame beams 2 are respectively located on the three sides of the side column, Moreover, the two frame beams 2 located on the two opposite sides of the side column belong to the case where their side faces and end faces are respectively flush with the two sides of a certain corner of the frame column prefabricated part 1, and the remaining frame beam 2 belongs to its The side and end faces are not respectively flush with the two sides of a certain corner of the frame column prefabricated part 1;

[0059] Embodiment 2 of the present invention is based on the above-mentioned inventive concept and the above-mentioned preferred structure, and adopts the following specific scheme: the upper end of the aluminum alloy sleeve mem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com