Iodine-containing polycarbonate/polyester material for X-ray development and preparation method and application thereof

A technology of polycarbonates and carbonates, which is applied in the field of iodine-containing polycarbonate/polyester polymers and its preparation, can solve problems such as easy decomposition of iodine-containing monomers, limited practical applications, and harsh storage conditions. Achieve excellent X-ray imaging performance, strong shape selectivity, and good thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Example 1, take 1.5g of serinol and dissolve it in 40mL of 10% sodium carbonate aqueous solution, add 15mL of 1,4-dioxane, and after 15min in ice-water bath, slowly add 4.47g of 4-iodo-benzoyl chloride solution (containing 7.5mL 1,4-dioxane), react in an ice-water bath for 1h, then react overnight at room temperature. Suction filtration, take the filter cake into 60mL aqueous solution and stir for 2h, then suction filtration again, and dry the filter cake at 80°C for 2h to obtain white powder N-(1,3-dihydroxy-2-propyl)-4-iodobenzene Formamide 4.76g, recorded as compound a, yield 90%.

Embodiment 2

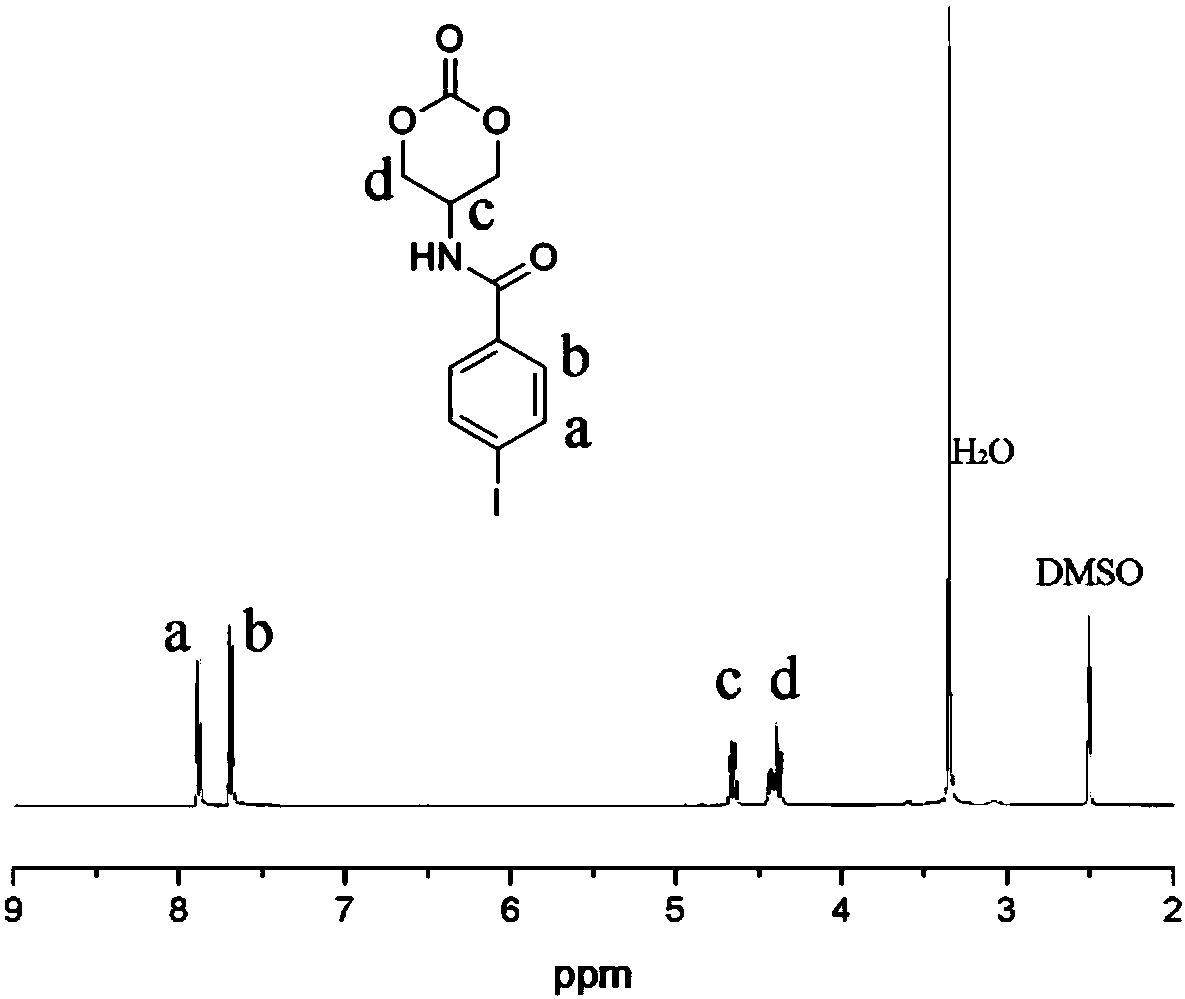

[0038] Example 2, take 0.5g of N-(1,3-dihydroxy-2-propyl)-4-iodobenzamide and add 25mL of anhydrous THF, add 0.3mL of ethyl chloroformate after ice-water bath for 10min, add dropwise 0.43 mL of triethylamine was added dropwise in 20 minutes. Suction filtration, the filter cake was added to 50 mL of tetrahydrofuran and stirred for 2 hours, then suction filtration, and the filter cake was dried at 80°C for 2 hours to obtain white powder 4-iodo-N-(2-oxo-1,3-dioxin-5- Base)-benzamide, denoted as compound b, yield 87%. figure 1 is it 1 H NMR spectrum.

Embodiment 3

[0039] Example 3, 3 g of 2,2 dibromomethyl-1,3-propanediol and 8 g of sodium iodide were added to 60 mL of acetone for dissolution, heated to reflux for 30 h, and the solvent was distilled off under reduced pressure, and sodium thiosulfate 10% (w / v) After 60mL, suction filtration, the filter cake was vacuum-dried at 60°C for 6h to obtain 3.7g of white powder 2,2-diiodomethyl-1,3-propanediol, which was designated as compound c, with a yield of 90%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Weight average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com