Synthesis method and application of AEN-structured Si-P-Al molecular sieve

A technology of silicon-phosphorus-aluminum molecular sieve and synthesis method, which is applied in the direction of molecular sieve characteristic silicon-aluminophosphate, molecular sieve and alkali-exchanged phosphate, separation method, etc., can solve the problems such as difficult synthesis of AEN structure silicon-phosphorus-aluminum molecular sieve, and achieve good application prospects , low addition ratio, easy synthesis effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

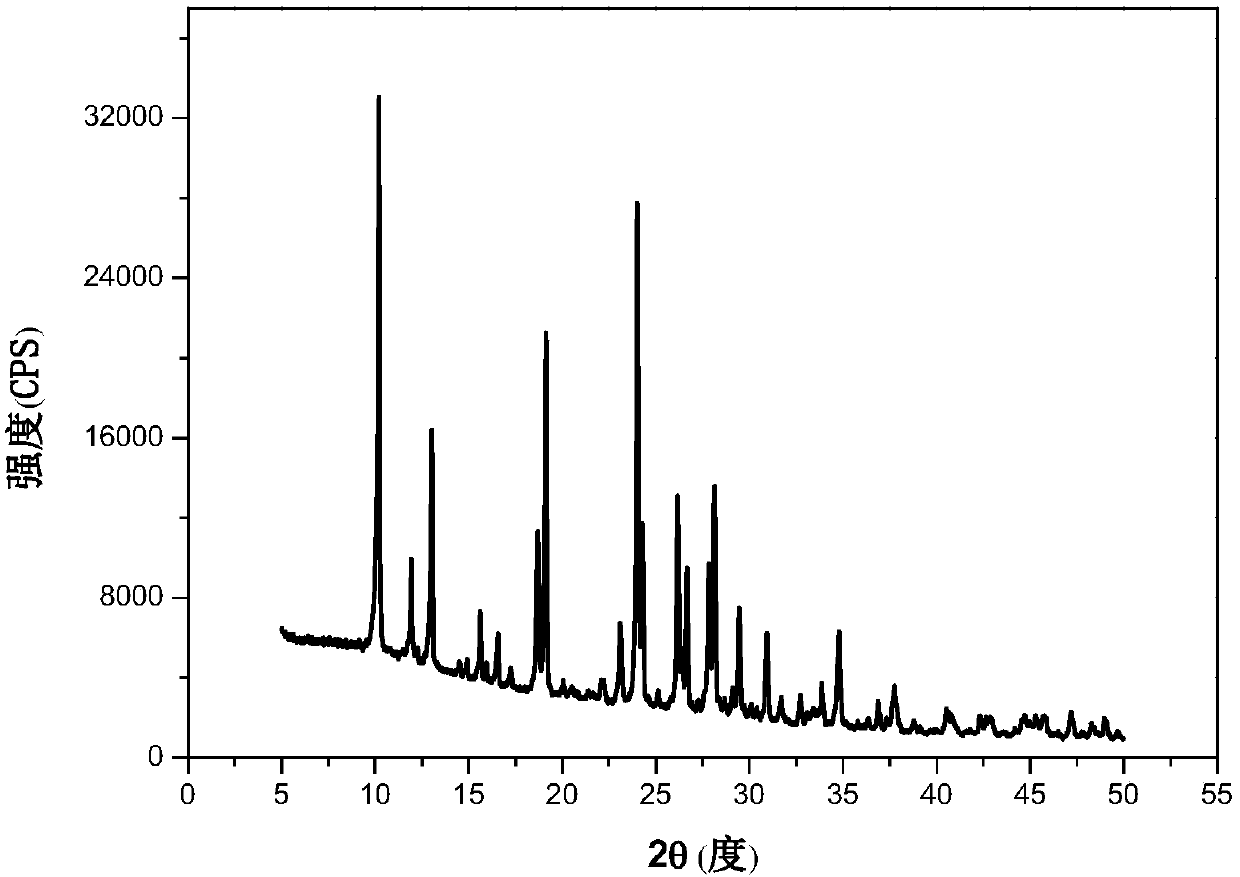

Embodiment 1

[0090] 4.91 g of pseudoboehmite (Al 2 o 3 Massfraction 83%) and 26.58 grams of deionized water are stirred and mixed to evenly, and 9.22 grams of orthophosphoric acid (H 3 PO 4 mass fraction 85%), fully stirred at 60°C, and aged for 18 hours to prepare mixture A. The mixture A was poured into a tray, and dried at 80° C. for 20 hours to obtain a phosphoraluminum xerogel.

[0091] Get 7.59 grams of obtained phosphorus-aluminum dry glue (solid content 80.3%) and add in the polytetrafluoroethylene lining, and add 0.75 grams of silica sol (SiO 2 Mass fraction 30%), 6.86 gram deionized water, 5.77 gram 1-methyl-4-piperidone (C 6 h 11 NO mass fraction 98%), stir evenly, wherein the adding molar ratio of each component is: P 2 o 5 / Al 2 o 3 =1.0, SiO 2 / Al 2 o 3 =0.15, R / Al 2 o 3 =2.0,H 2 O / Al 2 o 3 =20.

[0092] Cover the polytetrafluoroethylene liner with the above reaction mixture, put it into a stainless steel autoclave and seal it, place the autoclave in a rotar...

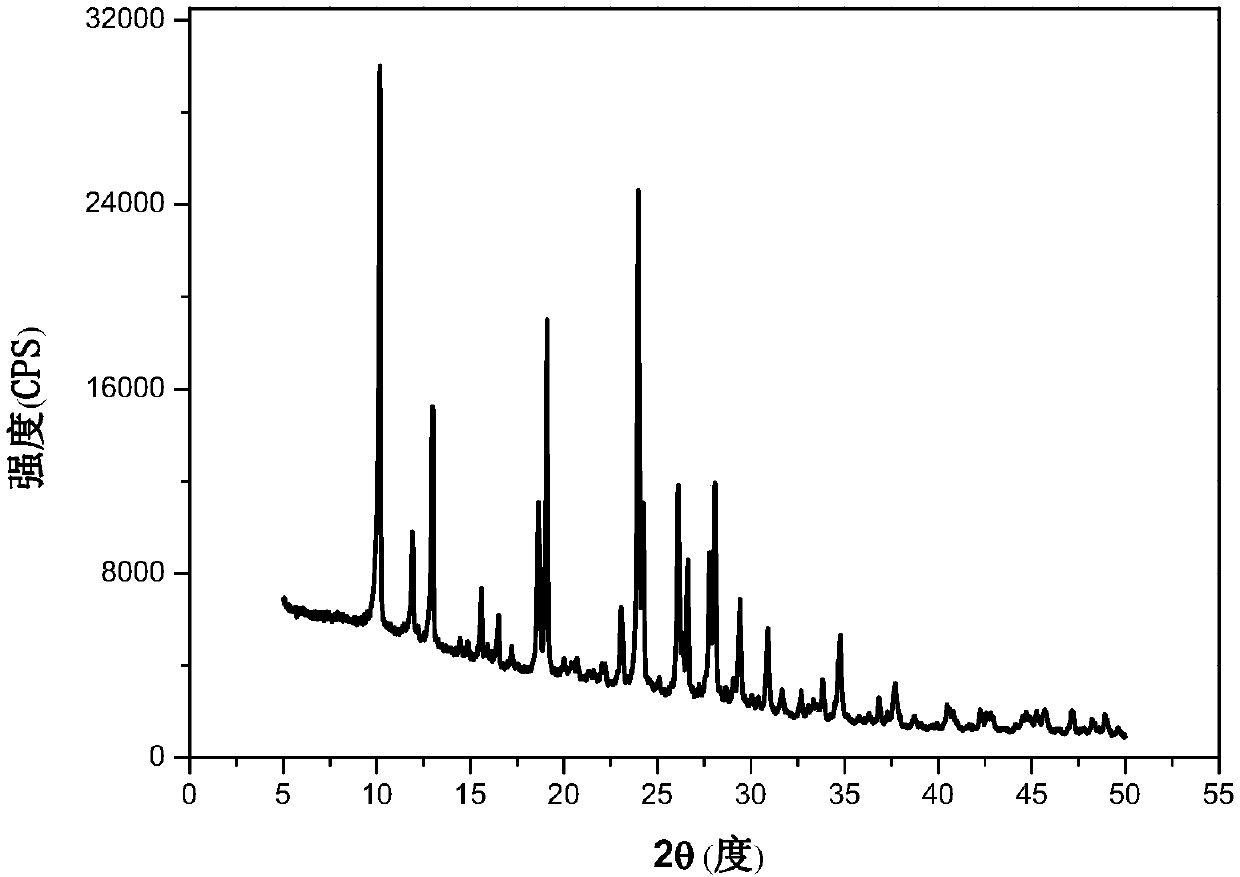

Embodiment 2

[0095] 4.91 g of pseudoboehmite (Al 2 o 3 Mass fraction 83%) and 34.95 grams of deionized water were stirred and mixed until uniform, and 10.78 grams of ammonium hydrogen phosphate ((NH 4 ) 2 HPO 4 mass fraction 98%), fully stirred at 60°C, and aged for 12 hours to prepare mixture A. The mixture A was poured into a tray, and dried at 80° C. for 24 hours to obtain a phosphoraluminum xerogel.

[0096] Get 7.63 grams of obtained phosphorus-aluminum dry glue (solid content 79.9%) and add in the polytetrafluoroethylene liner, and add 0.48 grams of solid silica gel (SiO 2 Mass fraction 93%), 5.10 gram deionized water, 4.33 gram 1-methyl-4-piperidone (C 6 h 11 NO mass fraction 98%), stir evenly, wherein the adding molar ratio of each component is: P 2 o 5 / Al 2 o 3 =1.0, SiO 2 / Al 2 o 3 =0.3, R / Al 2 o 3 =1.5,H 2 O / Al 2 o 3 =15.

[0097] Cover the polytetrafluoroethylene liner with the above reaction mixture, put it into a stainless steel autoclave and seal it, plac...

Embodiment 3

[0100] 5.44 grams of aluminum hydroxide dry glue (Al 2 o 3 Massfraction 75%) and 29.93 grams of deionized water, stir and mix to uniform, add 7.38 grams of orthophosphoric acid (H 3 PO 4 mass fraction 85%), fully stirred at 70°C, and aged for 12 hours to prepare mixture A. The mixture A was poured into a tray, and dried at 80° C. for 24 hours to obtain a phosphoraluminum xerogel.

[0101] Get 6.51 grams of obtained phosphorus-aluminum dry glue (solid content 82.7%) and add in the polytetrafluoroethylene lining, and add 0.77 grams of white carbon black (SiO 2 Mass fraction 98%), 10.02 gram deionized water, 4.33 gram 1-methyl-4-piperidone (C 6 h 11 NO mass fraction 98%), stir evenly, wherein the adding molar ratio of each component is: P 2 o 5 / Al 2 o 3 =0.8, SiO 2 / Al 2 o 3 =0.5, R / Al 2 o 3 =1.5,H 2 O / Al 2 o 3 =25.

[0102]Cover the polytetrafluoroethylene liner with the above reaction mixture, put it into a stainless steel autoclave and seal it, place the aut...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com