A lithium-ion battery positive and negative electrode slurry mixing production line and production process

A technology for lithium ion batteries and positive and negative electrodes is applied in the field of lithium ion battery positive and negative electrode slurry mixing production lines and production processes. , the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

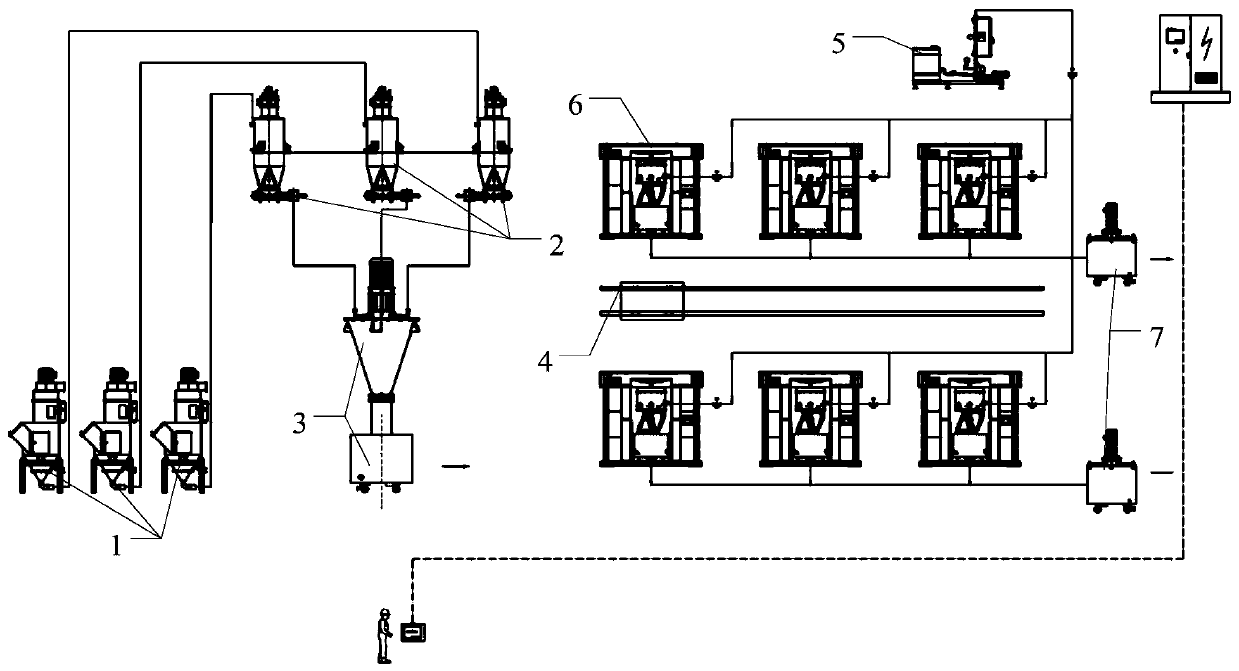

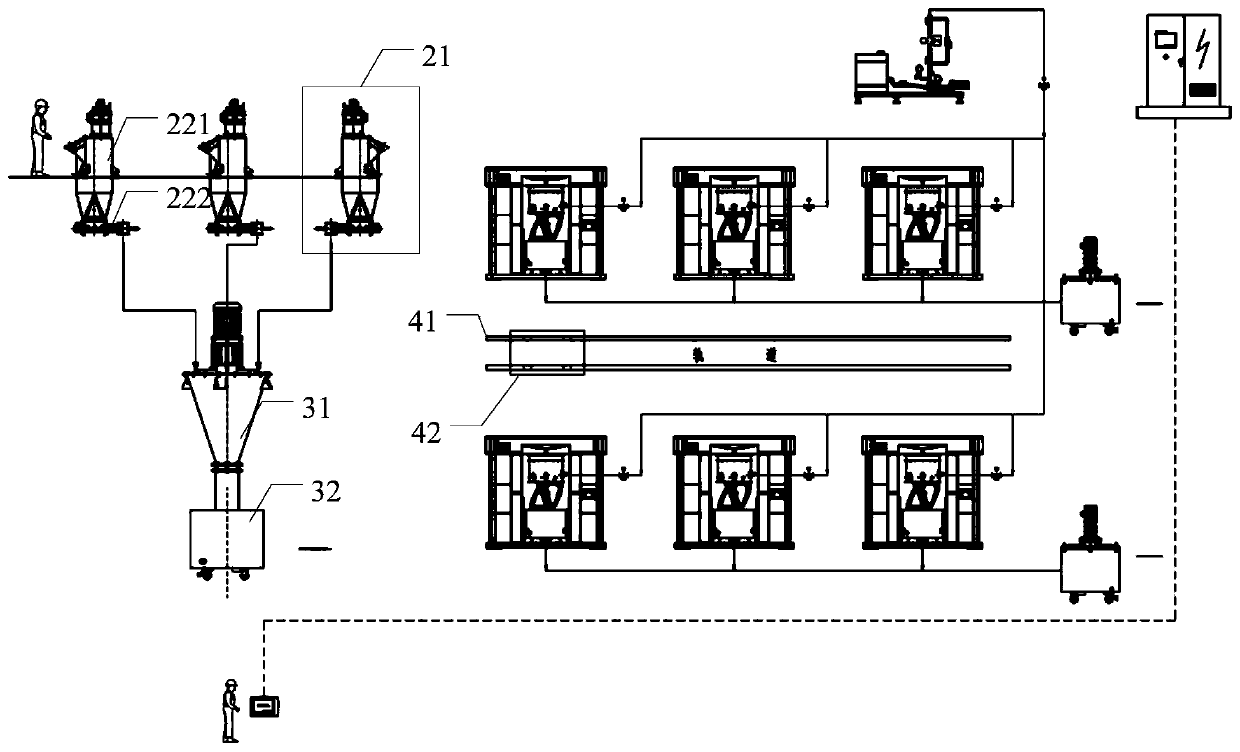

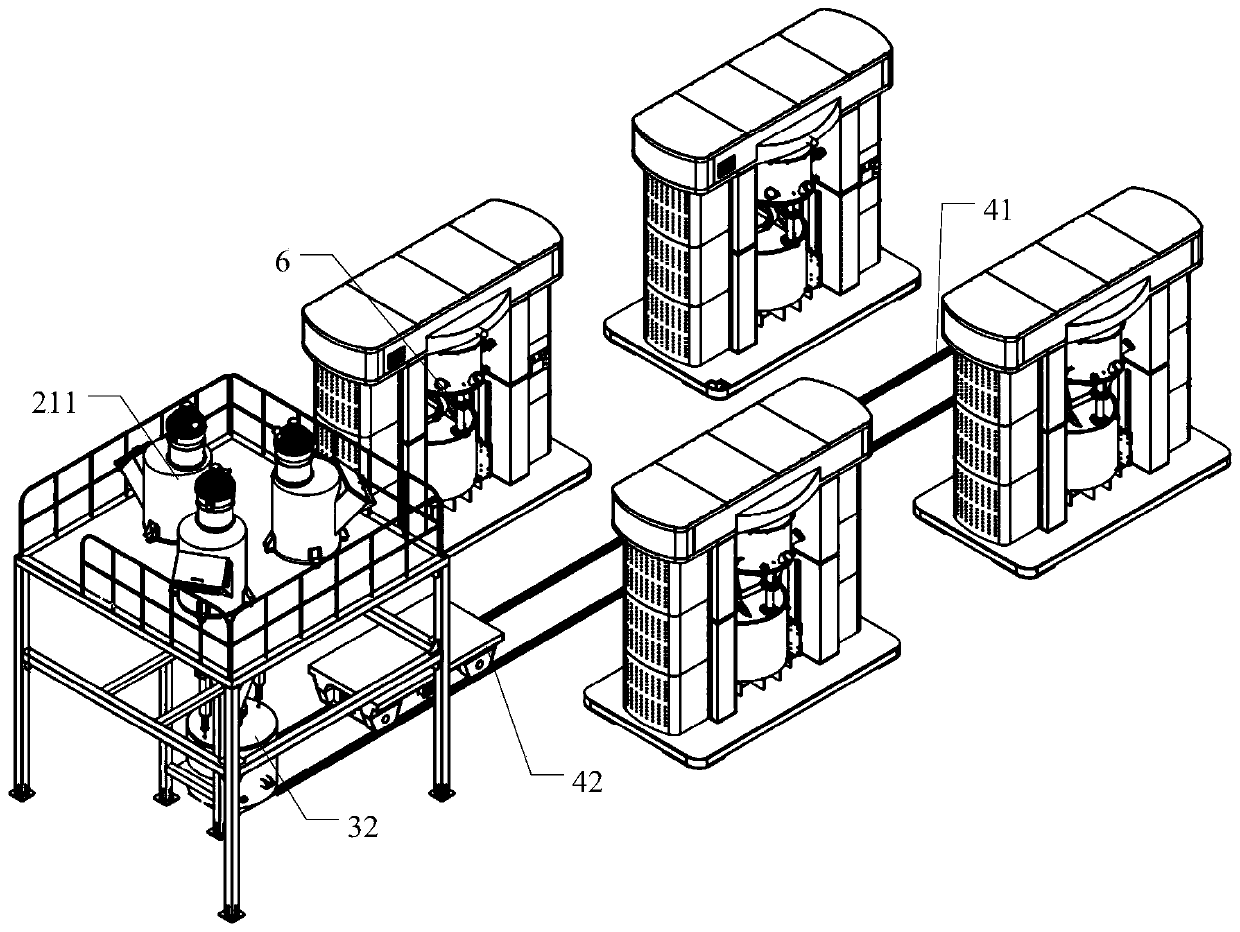

[0088] Whether it is the preparation of positive electrode slurry or negative electrode slurry, it is necessary to use a variety of different powder materials. Each powder material corresponds to a hopper. When working, the powder materials first need to be added to different hoppers of the feeding mechanism.

[0089] S2. The powder is measured by the weighing mechanism and transported to the twin-screw mixer for mixing;

[0090] The weighing mechanism measures the powder and transports it to the twin-screw mixer for mixing. During this process, the weighing mechanism adjusts the speed of powder feeding according to the mixing speed of the twin-screw mixer so that the twin-screw mixer can realize dynamic mixing. It can realize the mixing of powder more fully and efficiently.

[0091] S3, feeding the mixed powder into the bucket;

[0092] After the mixing of the ingredients is completed, the materials will be fed into the barrel. It should be noted that the number of barrels c...

Embodiment 1

[0121] PT300 dry mixing method (positive electrode slurry, taking lithium cobalt oxide as an example)

[0122]PT dry mixing pulping equipment consists of a set of weighing mechanism, RGV trolley system, solvent input mechanism, 4 PT7-300L planetary mixers, etc.; the weighing mechanism consists of one 600L measuring tank, two 400L measuring tanks, and 500L Composition of double screw mixing powder machine.

[0123] a1. Add active substances, conductive agents and binders to different hoppers of the feeding mechanism;

[0124] a2. The powder is measured by the weighing mechanism and then transported to the double-screw mixer. The double-screw mixer is rotating

[0125] The speed is 45rpm, and the powder is mixed for 20min;

[0126] a3. Feed the mixed powder into the bucket;

[0127] a4. According to the set route, the RGV trolley transports the material barrel to the idle planetary mixer;

[0128] a5. Add 50% solvent to the planetary mixer. The planetary mixer stirs the powd...

Embodiment 2

[0134] PT650 dry mixing method (negative electrode slurry, taking lithium cobalt oxide as an example)

[0135] The PT dry mixing pulping equipment consists of a set of weighing mechanism, RGV trolley system, solvent input mechanism, 6 PT7-650L planetary mixers, etc.; the weighing mechanism consists of one 1000L measuring tank, two 400L measuring tanks, and 1000L Composition of double screw mixing powder machine.

[0136] b1. Put graphite and binder into different hoppers of the feeding mechanism;

[0137] b2. The powder is measured by the weighing mechanism and then transported to the double-screw mixer. The double-screw mixer is rotating

[0138] The speed is 45rpm, and the powder is mixed for 20min;

[0139] b3. Feed the mixed powder into the bucket;

[0140] b4. According to the set route, the RGV trolley transports the material barrel to the idle planetary mixer;

[0141] b5. Add 50% of the solvent to the planetary mixer. The planetary mixer stirs the powder and solven...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com