Fruit and vegetable granules for being added into normal-temperature yogurt and preparation method of fruit and vegetable granules

A technology of fruit and vegetable granules and yogurt, which is applied in the direction of milk preparations, applications, dairy products, etc., can solve the problem of occupying the refrigeration space of dairy factories, and achieve the effect of good taste, good texture, and good chewing texture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

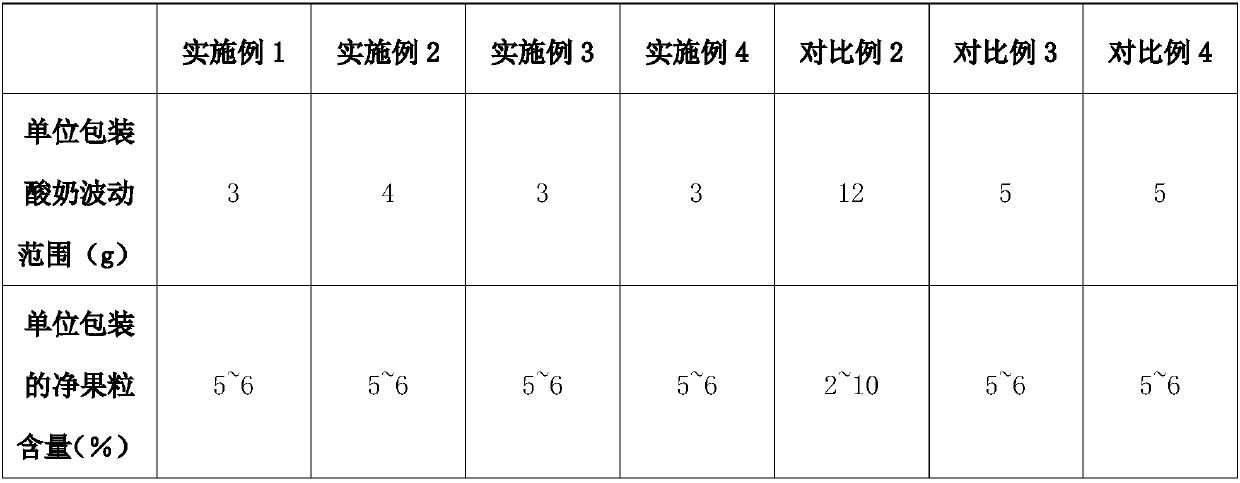

Examples

Embodiment 1

[0029] (1) Select blueberries, strawberries, raspberries and carrots as raw materials, cut (strawberries and carrots into cubes with a side length of 7mm, blueberries and raspberries choose particles with a particle size of 7mm) to make fruit pellets, the amount of fruit pellets added 50%, the ratio of blueberries, strawberries, raspberries and carrots is 1:1:1:2, add 40% white sugar, 0.3% propylene glycol alginate, 1% blueberry essence, 2% citric acid dissolved in 6.7% pure water, adjust the pH of the mixed fruit and vegetable to 3.0;

[0030](2) The mixed fruit and vegetable granules after the acid adjustment in step (1) are placed in a cooking pot at 80°C for 10 minutes, cooled to 10°C, and then pumped to a tube-type sterilizer for sterilization by a screw pump, and the sterilization condition is 121°C , the holding time is 30s, the discharge temperature after sterilization is 20°C, and under this condition, it is filled into aseptic ton tanks or aseptic bags for storage. ...

Embodiment 2

[0033] (1) select cranberries, peaches, apricots and cucumbers as raw materials, cut and make (peaches, apricots and cucumbers are cut into cubes with a side length of 5mm, and cranberries are selected as particles with a particle diameter of 5mm) fruit particles, The amount of fruit pieces added is 60%, and the ratio of cranberries, peaches, apricots and cucumbers is 1:1:1:2. Add 30% white sugar, 0.2% phosphorylated distarch phosphate, and 0.5% acetic acid to dissolve first In 9.3% purified water, adjust the pH of the mixed fruit and vegetable grains to 5.5;

[0034] (2) The mixed fruit and vegetable granules after the acid adjustment in step (1) are placed in a cooking pot at 100°C for 3 minutes, cooled to 20°C, and then pumped to a tubular sterilizer for sterilization by a screw pump, and the sterilization condition is 85°C , the holding time is 120s, the discharge temperature after sterilization is 30°C, and under this condition, it is filled into aseptic ton tanks or asep...

Embodiment 3

[0037] (1) Pick cucumbers as raw materials, cut them into cubes with a side length of 6mm, add 55% of the fruit, add 35% white sugar, 0.25% calcium chloride, and 1.3% lactic acid dissolved in 8.45% pure water , adjust the pH of the mixed fruit and vegetable grains to be 4.8;

[0038] (2) The cucumber granules after the acid adjustment in step (1) are placed in a cooking pot for 7 minutes at 87°C, cooled to 15°C, and then pumped to a tubular sterilizer for sterilization by a screw pump. The sterilization condition is 115°C. The holding time is 60s, and the discharge temperature after sterilization is 25°C, and under this condition, it is filled into aseptic ton tanks or aseptic bags for storage.

[0039] The prepared fruit and vegetable granules can be placed at room temperature for 9 months, wherein the net fruit content is 55%, the product viscosity is 6cm / min (measured by the Bostwick method), and the product uniformity of the fruit and vegetable granules is high. As measure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com