A Method of Reverse Construction of Subway Stations under Operating Conditions

A technology for subway stations and operating conditions. It is applied to earthwork drilling, underground chambers, temporary shields, etc. It can solve the problems of complex construction technology, long construction period, and high cost, and achieve the effect of ensuring construction safety.

Active Publication Date: 2019-04-02

SHANGHAI CONSTRUCTION GROUP

View PDF7 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

In view of the existing method of improving underground transport capacity by building new subway lines, there are problems such as complex construction technology, long construction period and high cost for connecting new and old subway stations

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

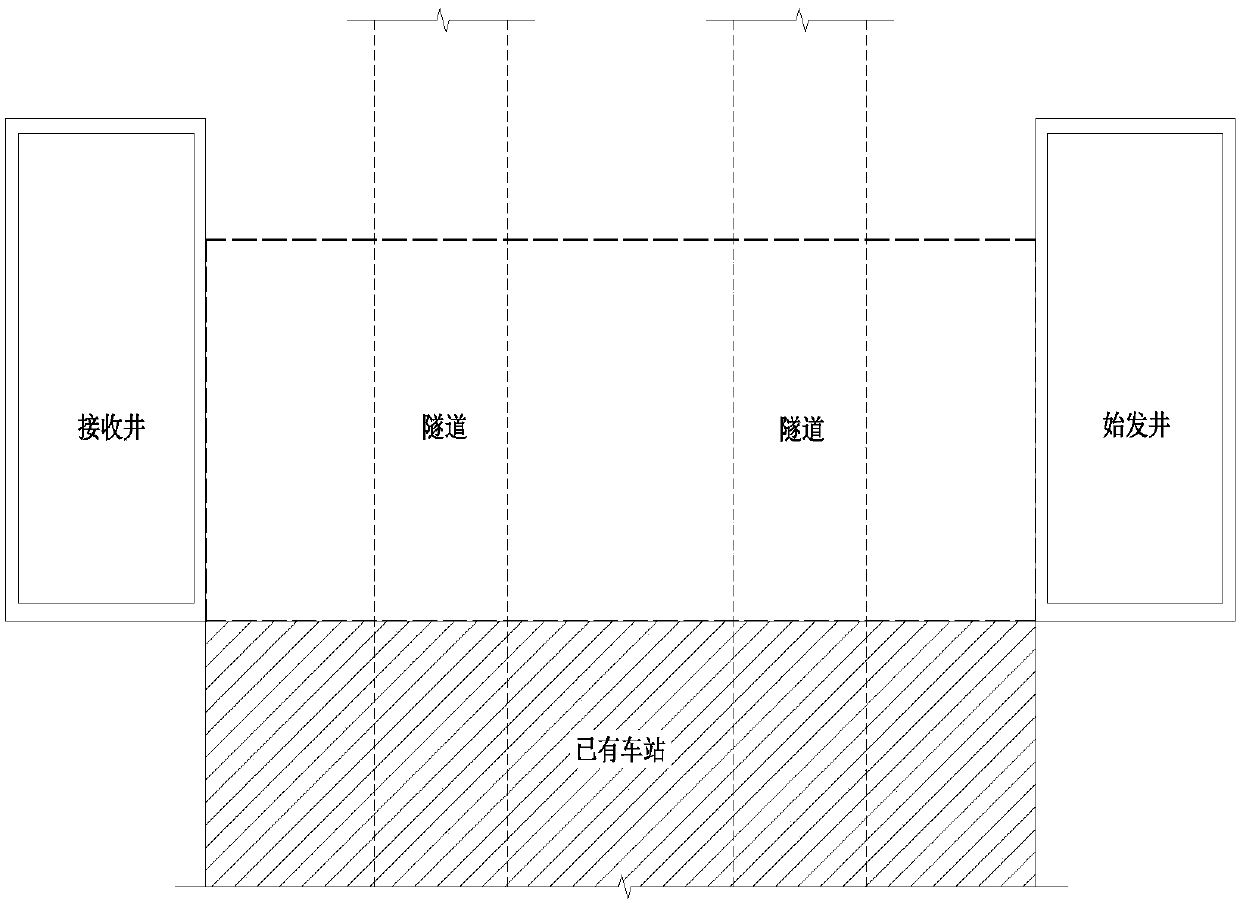

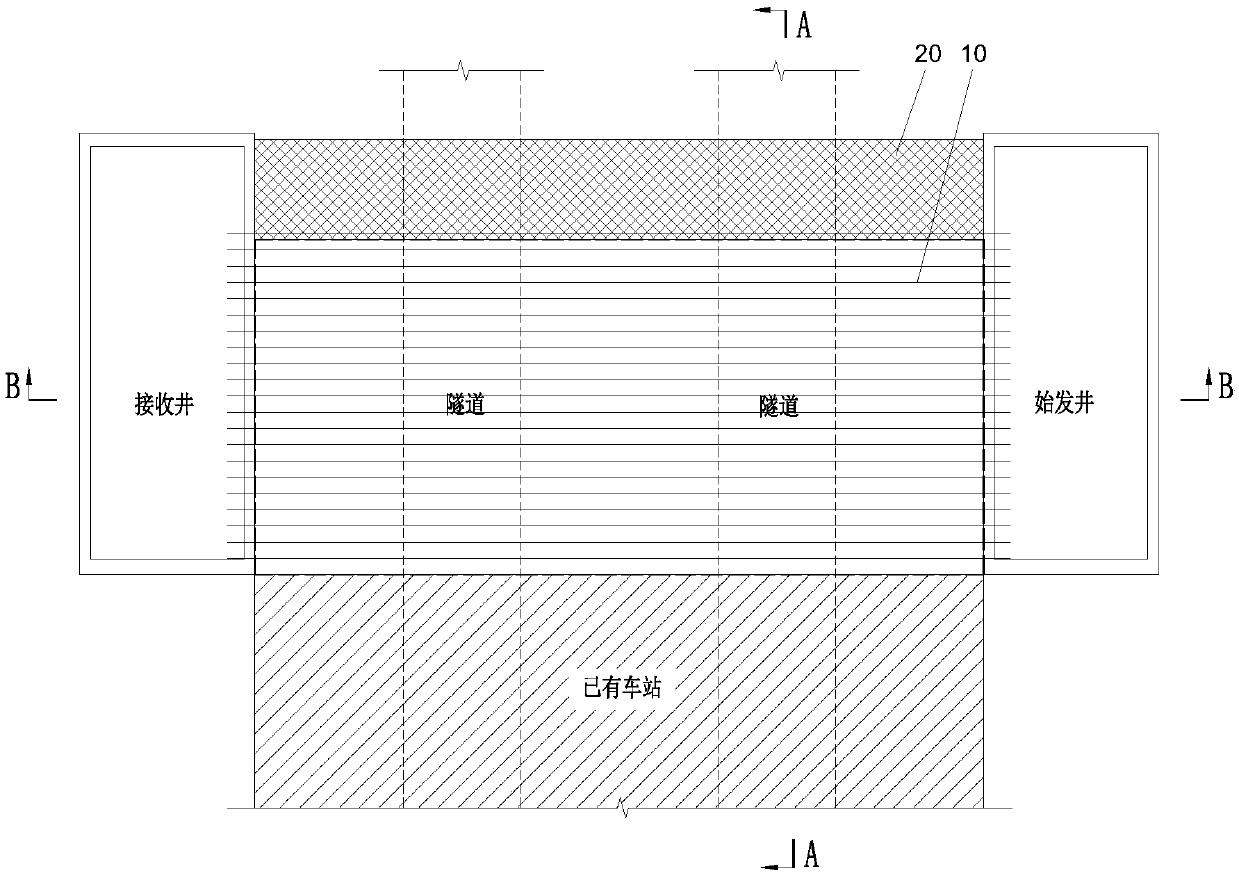

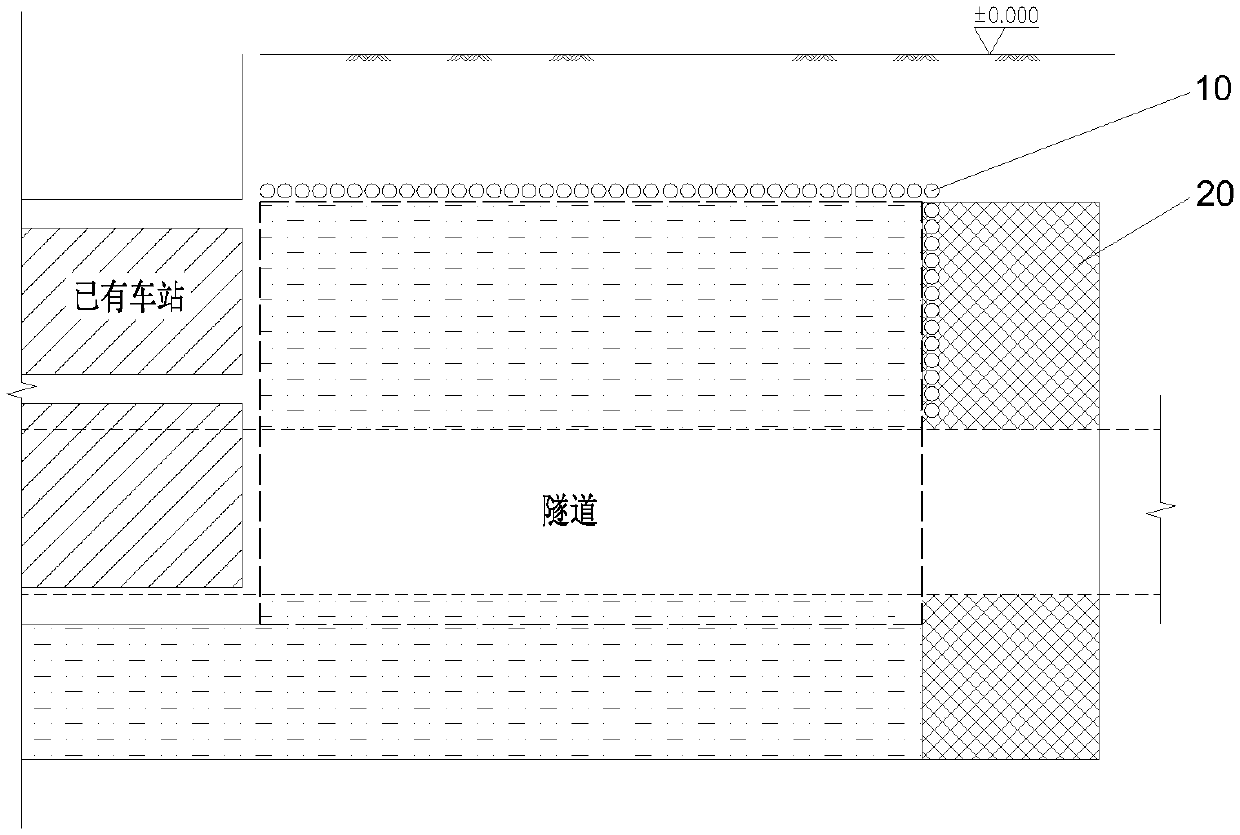

The invention discloses a subway station expanding method by using a reverse method under an operating condition, and relates to the technical field of underground space development. The subway station expanding method solves the problems of complex construction process, long construction period and the high construction cost of connecting of a new subway station and an old subway station and existed in a method for improving the carrying capacity by newly building subway routes. The subway station expanding method comprises the steps that 1, original well and receiving well construction is conducted; 2, pipe-shed construction and grouting reinforcement are conducted; 3, a first underground layer soil body is excavated, temporary support is arranged, steel pipe pile construction is conducted to build a vertical enclosure structure of a second underground layer, steel pipe piles are lengthened to make the tops of the steel pipe piles be connected with the top of a first underground layer, and first underground layer bottom plates are casted, and a soil taking opening is reserved; 4, a second underground layer soil body is excavated till the tunnel center height, an upper layer segment is removed, but bottom standard blocks are reserved; and excavating is continued to the bottom plate position of the second underground layer, and the bottom standard blocks are removed, cast-in-situ of bottom plates of second underground layer is conducted, prefabricated concrete bottom plates with tracks are laid, and the structure is connected with the existing station after being finished.

Description

technical field The invention relates to the technical field of underground space development, in particular to a reverse construction and expansion method of a subway station under operating conditions. Background technique With the increasing population of central cities, the ground transportation has been far from meeting the travel requirements of the majority of residents, and the development of underground transportation is imperative. At present, in China, new subway lines and new subway stations are mainly used to improve underground transport capacity. This method has the following disadvantages when applied to central urban areas: 1) The cost of new subway lines is high, and the construction of central urban areas needs to consider the surrounding demolition and pipeline displacement. Complex situation, high cost, and long construction period; 2) The construction process for the connection between the new subway line and the existing subway station is complicated, ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): E21D9/00E21D11/10E21D5/04E21D19/04

CPCE21D5/04E21D9/00E21D9/001E21D11/003E21D11/10E21D19/04

Inventor 吴小建程子聪孙廉威王新新

Owner SHANGHAI CONSTRUCTION GROUP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com