High-temperature-resistant and corrosion-resistant stable roller

A corrosion-resistant and high-temperature-resistant technology, which is applied in the field of hot-dip galvanizing, can solve the problems of time-consuming and troublesome assembly or disassembly of rollers and roller shafts, time-consuming and laborious assembly or disassembly, and small cross-sectional area of zinc liquid flow, etc., to achieve assembly Or it is convenient and quick to disassemble, easy to disassemble, and reduce the effect of sticky residue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below according to the accompanying drawings and in conjunction with the embodiments.

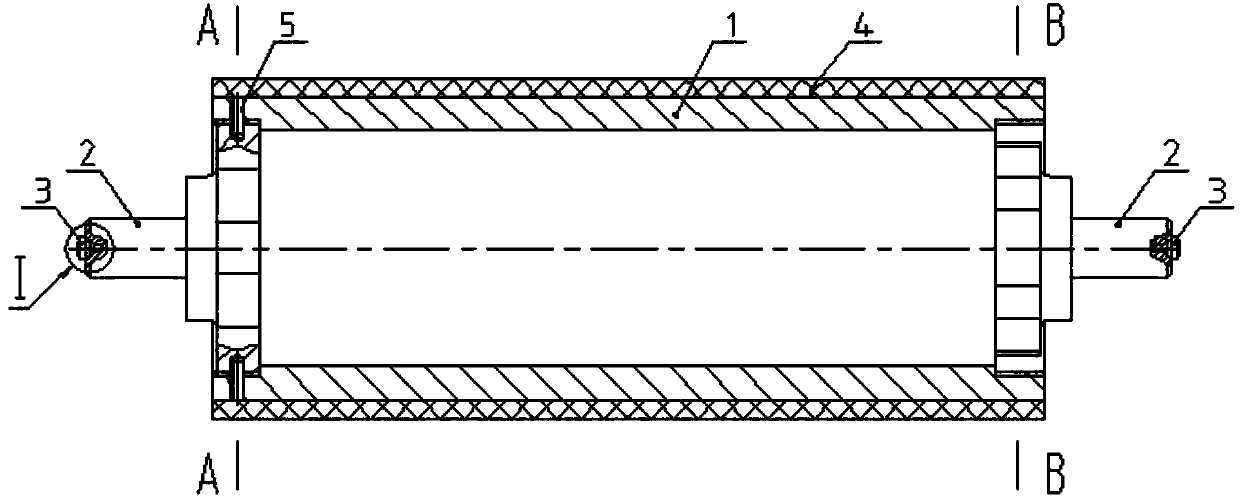

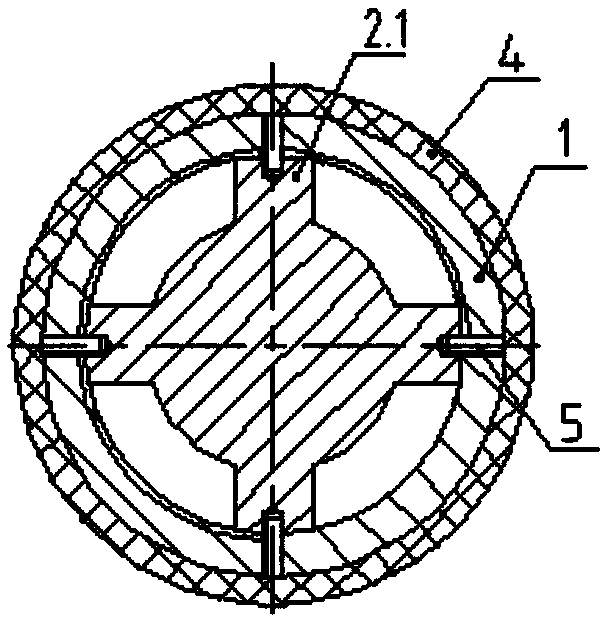

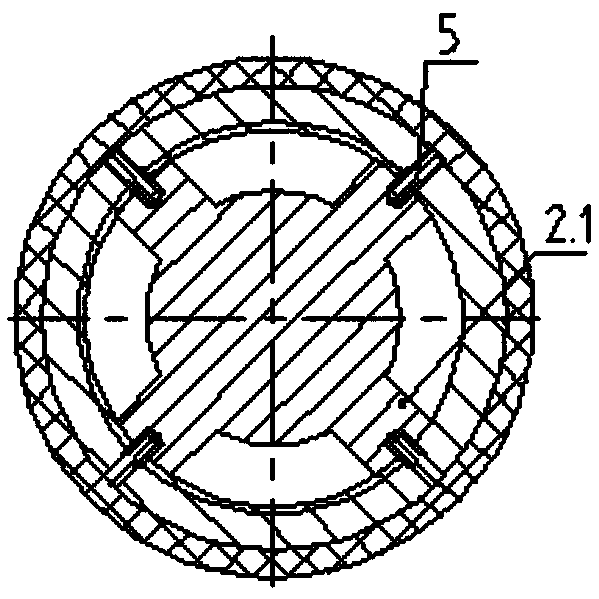

[0025] The high-temperature-resistant and corrosion-resistant stabilizing roller shown in the accompanying drawings includes a roller 1 and a roller shaft 2 connected to both ends of the roller 1; the end of the roller shaft 2 connected to the roller 1 is made of four webs 2.1 evenly distributed on the circumference Radial plate structure (in other embodiments, the end connecting the roller shaft 2 and the roller 1 is a radial plate structure with 3 or more than 4 radial plates 2.1 uniformly distributed on the circumference); the outer circumference of the radial plate 2.1 is provided with external threads , and threadedly connected with the inner threaded hole at the end of the roller 1.

[0026] There are 4 anti-loosening screws 5 at the threaded joint between the inner threaded hole at the end of the roller 1 and the threaded plate 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com