A kind of multi-strain brewing citrus type balsamic vinegar based on tangerine concentrated juice and its preparation method

A tangerine-type and concentrated juice technology is applied in the field of multi-strain brewing of citrus-type balsamic ester vinegar and its preparation, which can solve the problems of unreported process, lack of high-end vinegar products, and single type and form.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] (1) Preparation of tangerine juice: fresh tangerines without rot and pests, washed, peeled, and cut into volumes not exceeding 0.5cm 3 Small pieces of tangerines are pressed to obtain tangerine juice, which is used as a fermentation material;

[0030] (2) Fermentation: Tangerine juice is packed into a fermenter, and inoculated with 1% (V / V) Saccharomyces cerevisiae and 1% (V / V) Acetobacter aceticum, and the total number of colonies inoculated is 5 × 10 4 CFU / mL. Place the inoculated tangerine juice at 30°C for static fermentation for 7 days to complete the sugar-alcohol conversion and alkyd-acid conversion process;

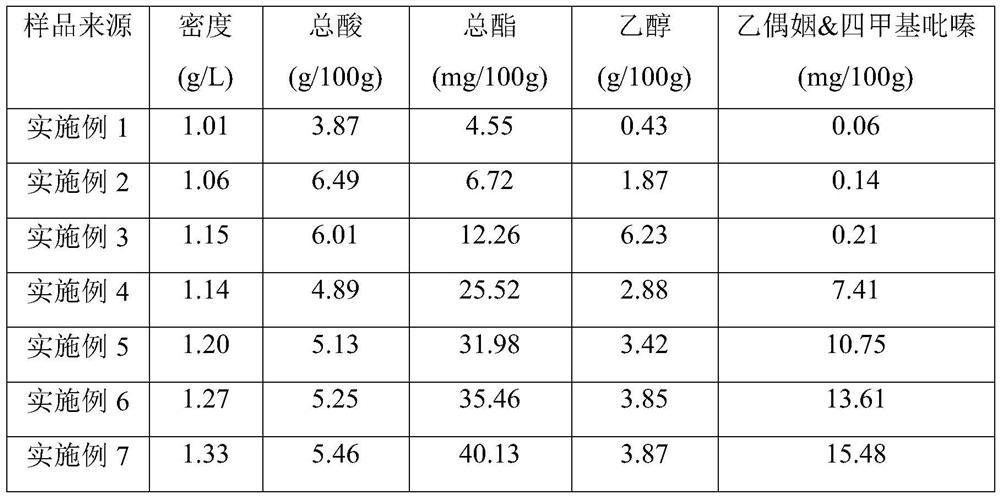

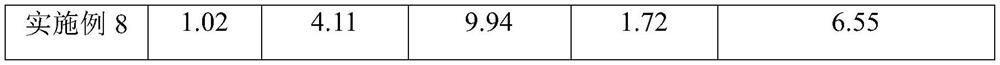

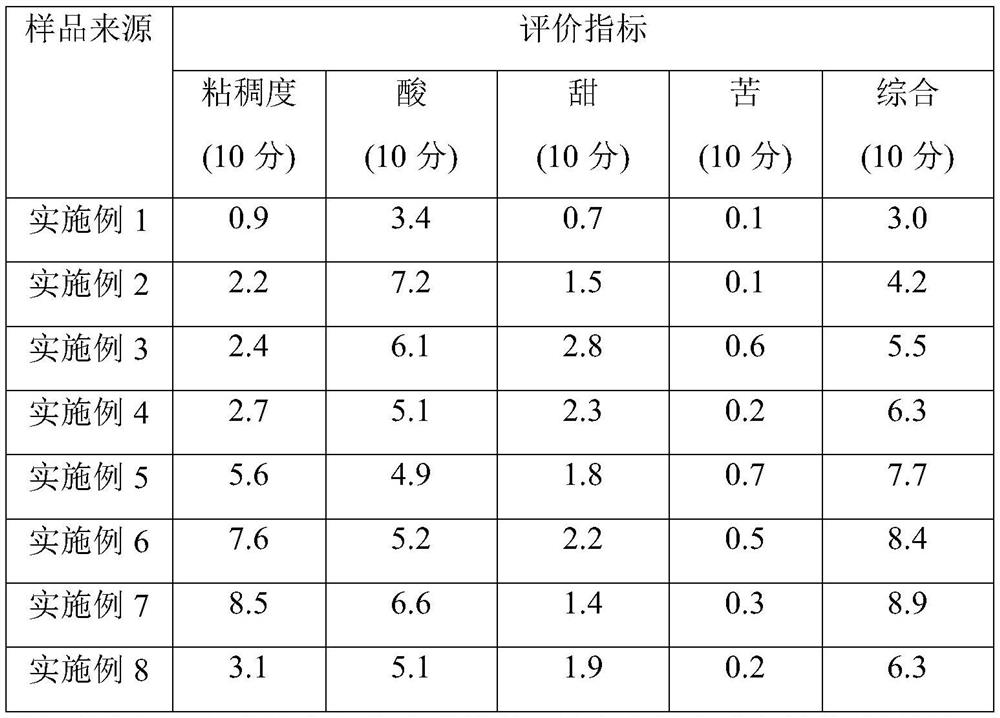

[0031] (3) After the fermentation is completed, detect the content of density, total acid, total ester, ethanol, acetoin and tetramethylpyrazine, and comprehensively evaluate the product according to evaluation and analysis indicators such as viscosity, acidity, sweetness and bitterness, The results are shown in Table 1 and Table 2.

Embodiment 2

[0033] (1) Preparation of concentrated tangerine juice: fresh tangerines without rot and pests, washed, peeled, and cut into volumes not exceeding 0.5cm 3 Squeeze small pieces of tangerine juice to obtain tangerine juice, then heat to 90°C for evaporation and concentration, and keep stirring during this period, stop heating after the volume is concentrated to one-third of the original volume, and cool to room temperature;

[0034] (2) Fermentation: Put the tangerine concentrated juice into the fermenter, and inoculate 1% (V / V) Saccharomyces cerevisiae and 1% (V / V) Acetobacter aceticum, and the total number of colonies inoculated is 7×10 4 CFU / mL. Place the inoculated tangerine concentrated juice at 30°C for 9 days to ferment for 9 days to complete the process of sugar-alcohol conversion and alkyd-acid conversion;

[0035] (3) After the fermentation is completed, detect the content of density, total acid, total ester, ethanol, acetoin and tetramethylpyrazine, and comprehensive...

Embodiment 3

[0037] (1) Preparation of concentrated tangerine juice: fresh tangerines without rot and pests, washed, peeled, and cut into volumes not exceeding 0.5cm 3 Squeeze small pieces of tangerine juice to obtain tangerine juice, then heat to 80°C for evaporation and concentration, and keep stirring during the period, stop heating after the volume is concentrated to one-third of the original volume, and cool to room temperature;

[0038] (2) Pre-fermentation: the concentrated tangerine juice is packed into oak barrels, and the mixed seed liquid of microorganisms such as yeast and Acetobacter acetobacter is inoculated, the total volume of the mixed seed liquid inoculated is 1% of the volume of the concentrated tangerine juice, and the total The number of colonies is 1×10 5 CFU / mL, wherein the cell number ratio of yeast: Acetobacter aceti is 1:1, and the cell number ratio of Saccharomyces cerevisiae: Luxie: Torulopsis globosa is 2:1:2. Place the inoculated tangerine concentrated juice ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com