Steaming and stir-frying pot discharging opening material door structure

A technology for steaming and frying pans and material gates, which is applied in the production of fat, fat oil/fat, etc., can solve the problem of stuck drag plate driving force, etc., and achieve the effect of avoiding long downtime for maintenance, stable operation and avoiding stuck.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

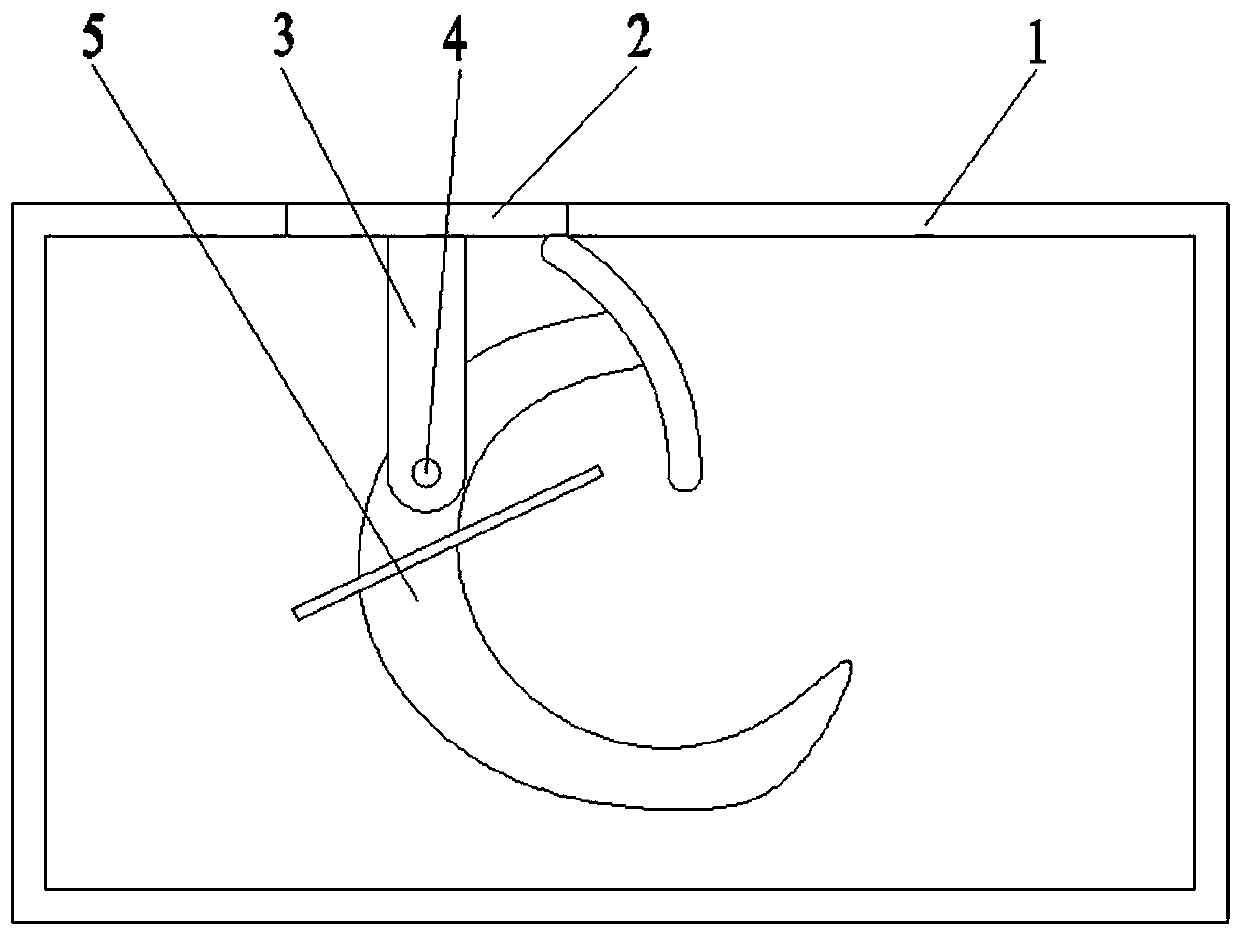

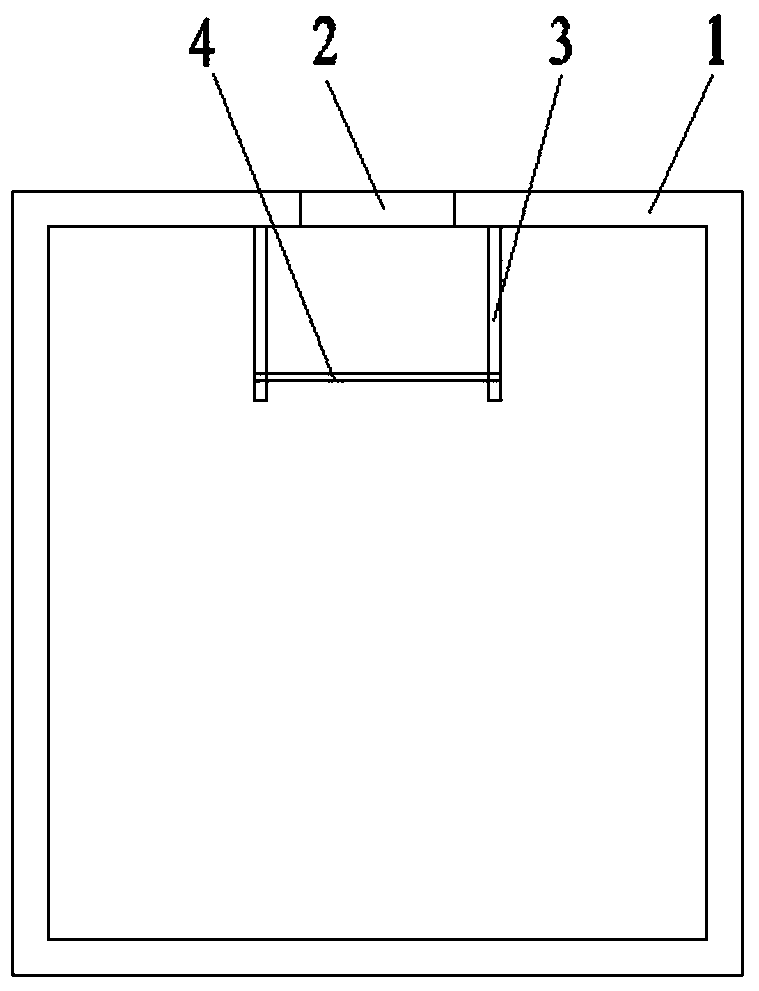

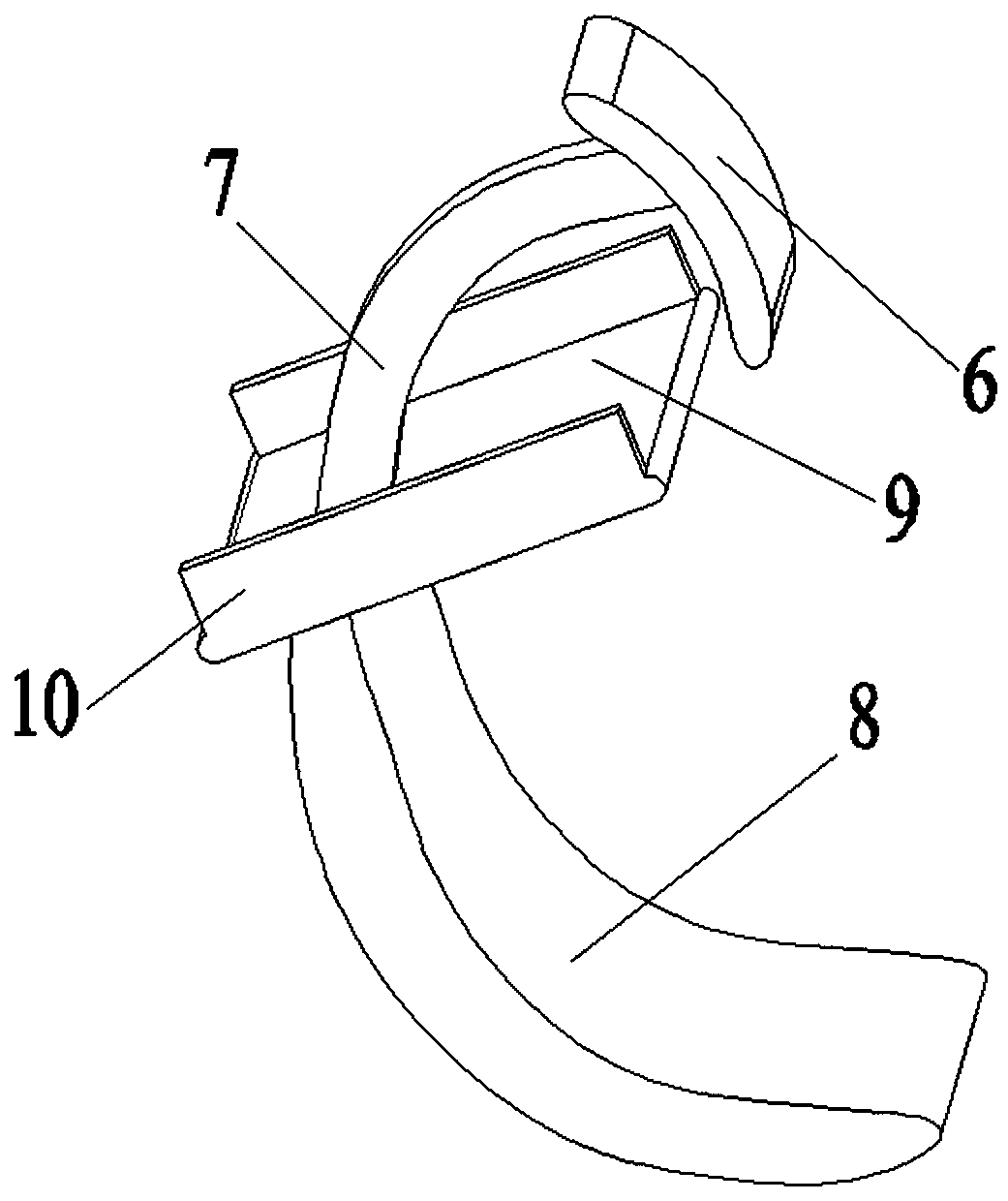

[0015] As shown in the accompanying drawings, a material gate structure of a steaming and frying pan includes a material bin 1, a rectangular material inlet 2 and a material pendulum 5, and lifting lugs 3 are fixed on the left and right sides below the rectangular material inlet 2. , the material pendulum 5 is suspended and fixed in the middle of the two lifting lugs 3 through the rotating shaft 4; the material pendulum 5 includes a material door 6 and a carriage 8 connected by a curved connecting rod 7, and a downward-sloping carriage 8 is fixed above the carriage 8 The sliding material plate 9; the material gate 5 is adapted to match the feed port 2 and is a downwardly curved arc shape, and the dragging plate 8 is an upwardly curved arc-shaped plate. Baffle plates 10 are fixed on the left and right sides of the slide plate 9 . The left and right sides...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com