A kind of pressing equipment and its method for pressing tea seed oil

A technology for tea seeds and equipment, applied in the field of pressing equipment and tea seed oil, can solve the problems of insufficient friction force and low oil yield of tea seeds, and achieve the effects of even frying, large friction force and reducing storage space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

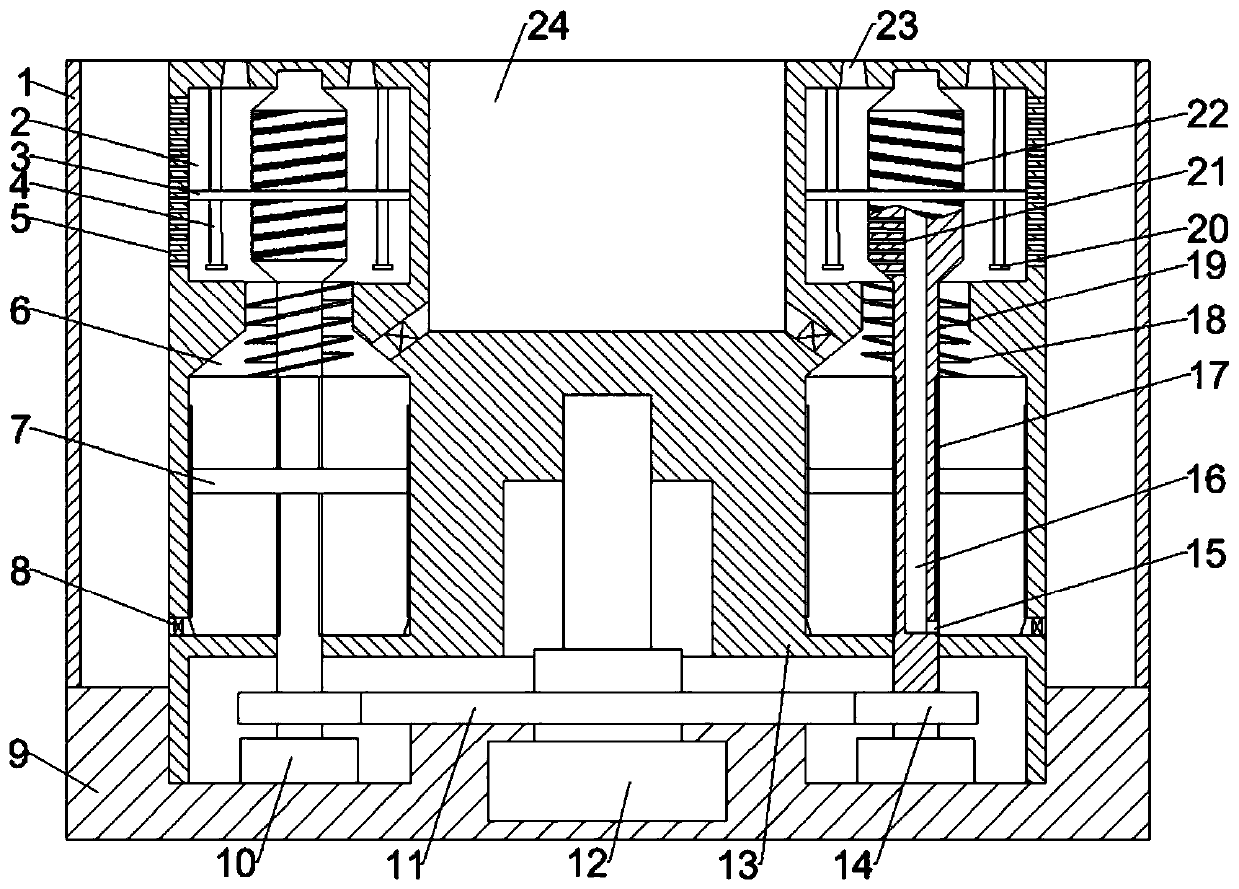

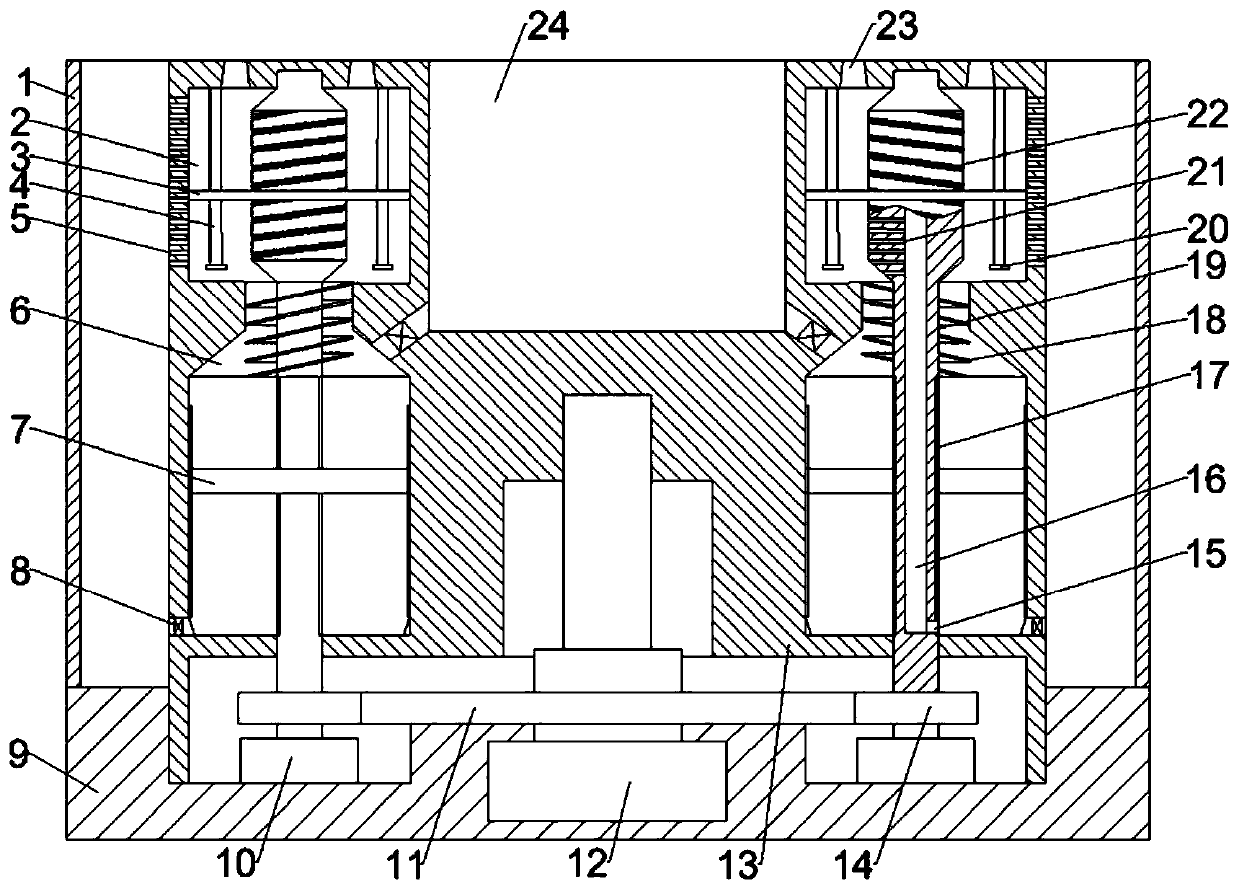

[0030] Such as figure 1 The pressing equipment shown comprises base 9, and the center of base 9 is provided with circular groove, and the center of groove is provided with motor 12, and the both sides of motor 12 is provided with bearing seat 10; Oil drum 1, the groove is located in the oil drum 1, the output shaft of the motor 12 is fixed with the first gear 11, the end of the output shaft of the motor 12 is fixed with a rotating shaft, and the rotating shaft is fixedly connected with a rotating body 13; 12 is driven to rotate in the groove; the rotating body 13 is provided with an oil pressing chamber 2, a feeding chamber 6 and a frying chamber 24, the frying chamber 24 is located in the middle of the rotating body 13, and the side wall of the frying chamber 24 is provided with Positioning line, the volume from the positioning line to the bottom of the frying chamber 24 is the same as that of the feeding chamber 6; both the oil pressing chamber 2 and the feeding chamber 6 ar...

Embodiment 2

[0037] The difference between embodiment 2 and embodiment 1 is that when the tea seeds are fried, the time for frying is 35 minutes, and the temperature for frying is 105°C.

Embodiment 3

[0038] The difference between embodiment 3 and embodiment 1 is that when the tea seeds are roasted, the roasting time is 40min, and the roasting temperature is 95°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com